8

Section 3 Installation

DANGER

Only qualified personnel should conduct the installation tasks described in

this section of the manual. The 1720E/sc100 product configuration is not

intended for installation in hazardous locations.

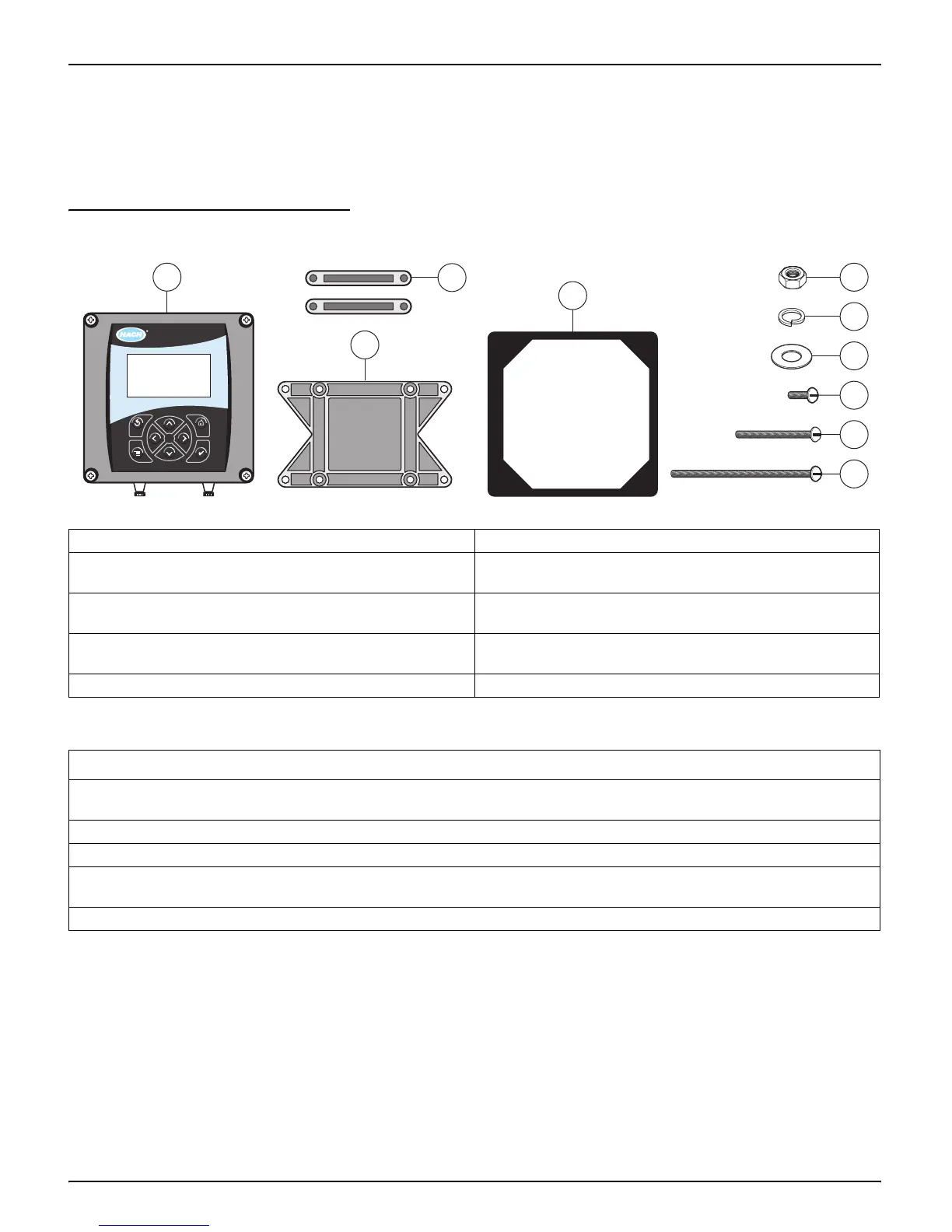

Figure 2 Controller Mounting Components

3.1 Mechanical Installation

Install in an environment that is protected from corrosive fluids. The sensor is

adversely affected by ClO

2

. Install the sensor in an area well ventilated from any

corrosive liquids or gasses.

1. Controller 6. Lock washer, ¼-inch I.D. (4), Cat. No. 8H1336

2. Mounting foot for panel mounting (2),

Cat. No. 1000B4F3222

7. Flat washer, ¼-inch I.D. (4), Cat. No. 8H1346

3. Bracket for panel and pipe mounting,

Cat. No. 1000C4F3217-101

8. Pan head screws (4), M6 x 1.0 x 20 mm, Cat. No. 58674-00

4. Gasket for panel mounting, rubber,

Cat. No. 1000A4F3249-101

9. Pan head screws (4), M6 x 1.0 x 100 mm, Cat. No. 5867500

5. Hex nut, M6 (4), Cat. No. 5867300 10. Pan head screws (4), M6 x 1.0 x 150 mm, Cat. No. 5867600

Table 3 Customer-supplied Items

Item

14-AWG wire for electrical power connections in conduit or if allowed by local electrical codes, 115 or 230 V ac power cord plus a

NEMA 4X-rated strain relief

High-quality, shielded instrumentation cable for connecting the analog outputs plus a NEMA 4X-rated strain relief

Mounting hardware for the sensor

Sun shield for mounting configurations where the sun strikes the front of the display (available from the manufacturer, order

separately). See Figure 8 on page 11.

Common hand tools

1

3

4

8

5

6

7

9

10

2

sc100

Loading...

Loading...