Rev.7 2

MACHINE SPECIFICATIONS

Power 240/120 VAC (3 pole, 4 wire) single phase, 60 Hz 30 Amp (240 VAC – line to line)

Requirements (120 VAC = each line to neutral)

Air Requires one air drop: One 1/2” tubing (minimum) with ¼” NPT fitting,

Requirements 20 CFM at 80 PSI to the Form Fill & Seal Machine (total 20 CFM).

Water Water supply with minimal pressure, ¼” tubing (maximum) with 1/8” NPT fitting to

Requirements the Form, Fill, & Seal Machine. Recommended sediment filter and shut-off valve.

Machine Size 11’5” maximum length by 3’6” maximum width by 6’8” to 7’9” maximum height.

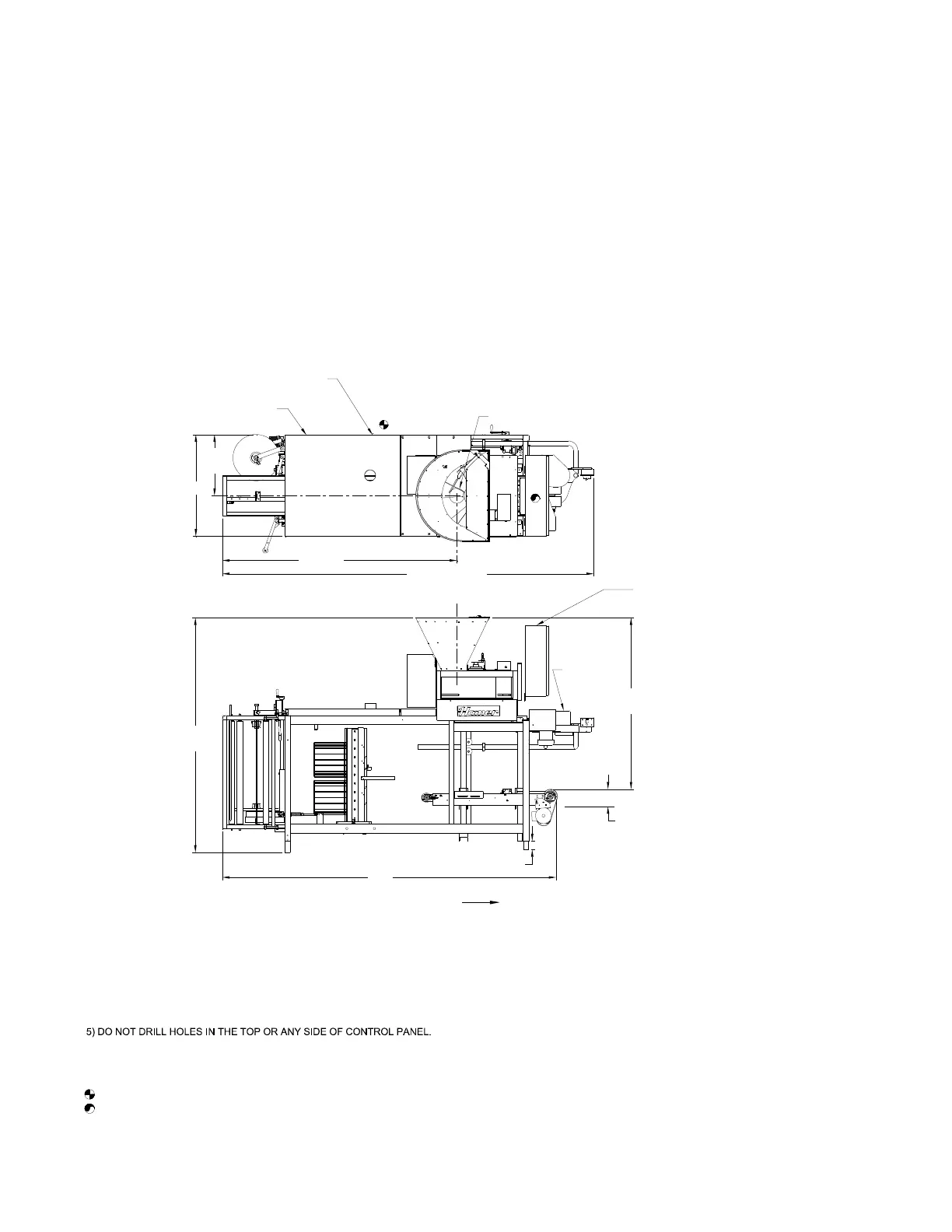

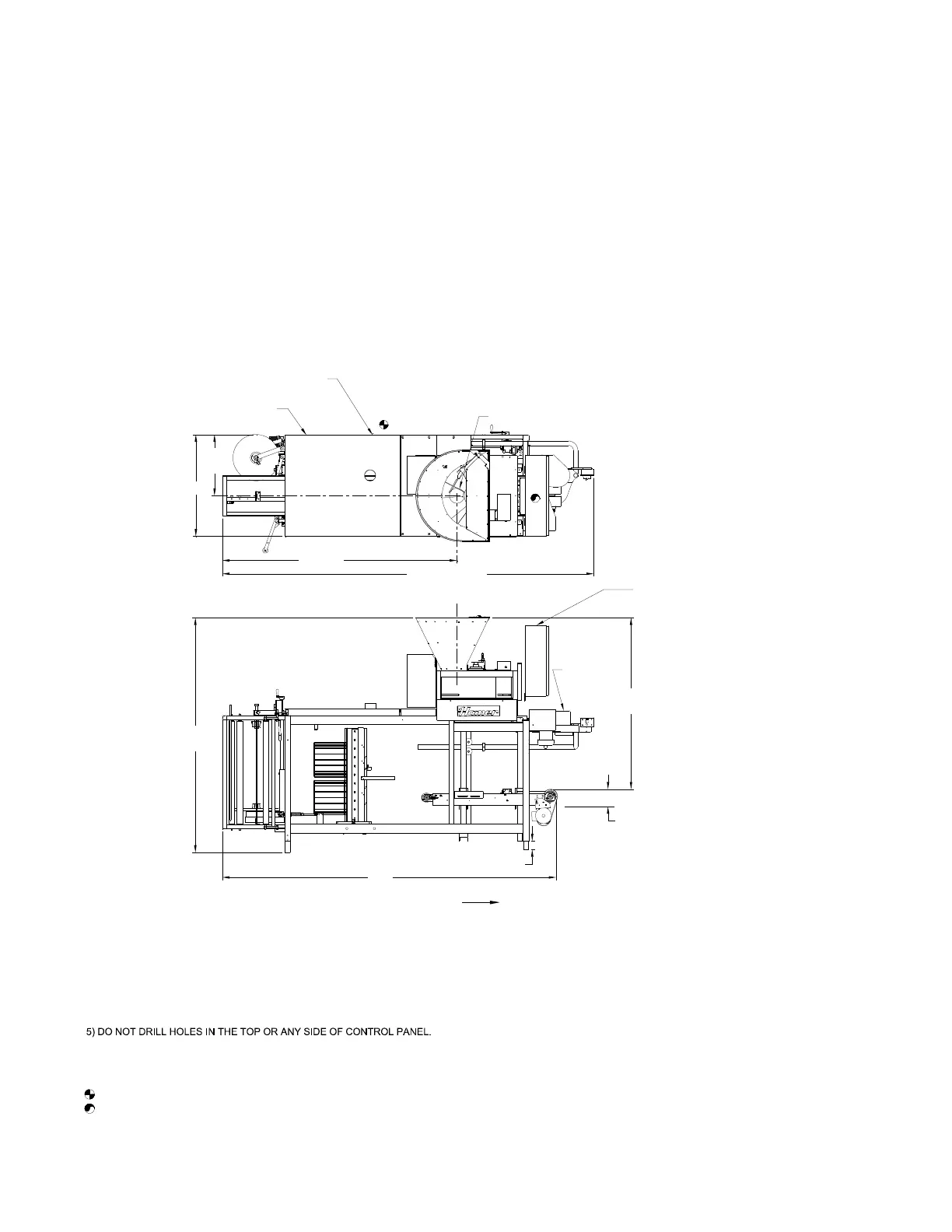

MACHINE LAYOUT

6" MINIMUM DISTANCE TO TOP

OF CUSTOMER CONVEYOR

79.5" MIN

93" MAX

60"

SEE NOTE 2

115"

81" REF.

21"

REF.

35"

FEED DIRECTION

AIR IN 20 CFM @ 80 PSI

1/2" TUBE MINIMUM

WATER (CLEAN) IN

1/2" TUBE MINIMUM

CONTROL PANEL (ONE DROP INCLUDES)

120 / 240 VAC 1-PHASE 60HZ 30 AMP

(4 WIRE WITH NEUTRAL)

(120 VAC = EACH LINE TO NEUTRAL)

(240 VAC = LINE TO LINE)

SEE NOTE 5

PRODUCT INFEED

FACTORY SET LEGS TO 3"

128" - 137" REF.

MODEL 125

BAG CLOSER

NOTES:

1) ALL DIMENSIONS ARE IN INCHES.

2) 60" NEEDED FOR 21" BAGS. DIMENSIONS CHANGE

ACCORDING TO BAG SIZE, AND SOME ADJUSTMENTS MAY

BE REQUIRED. (THIS DIMENSION INCREASES 1" FOR EACH

ADDITIONAL 1" OF BAG LENGTH)

3) MACHINE SHOULD BE LOCATED WITH A MINIMUM OF 2 FT.

CLEARANCE ON ALL FOUR SIDES

4) ALL AIR INPUTS REQUIRE CLEAN DRY AIR.

ALL WIRES MUST GO IN THROUGH THE BOTTOM OF THE CONTROL

PANEL. ANY MODIFICATIONS TO THE CONTROL PANEL

MAY VOID MANUFACTURES WARRANTY!

6) SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE.

*

AIR DROPS

ELECTRICAL DROPS

*

Loading...

Loading...