1-8 Torsional stiffness

1-9

Overview of the RSF supermini series

1-8 Torsional stiffness

When a torque is applied to the output flange of the actuator with the motor locked, the resulting

torsional wind up is near proportional to the torque.

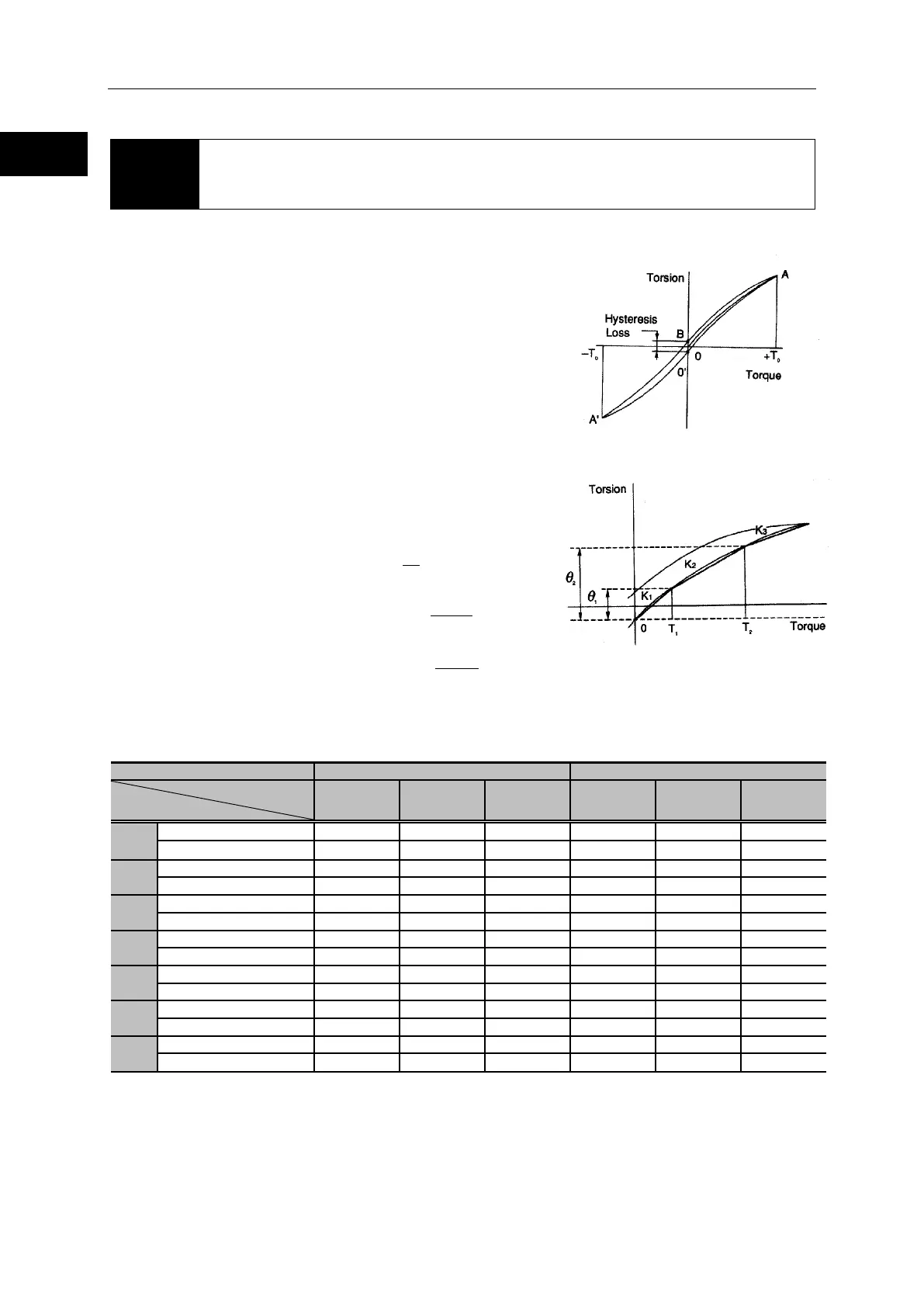

The upper right figure shows the torsional stiffness

characteristics of the output flange applying torque starting

from zero to plus side [+T

0] and minus side [–T0]. This

trajectory is called torque-torsion characteristics which

typically follows a loop 0→A→B→A’→B’→A as illustrated. The

torsional stiffness of the RSF supermini actuator is expressed

by the slope of the curve that is a spring rate (wind-up)

(unit:N・m/rad).

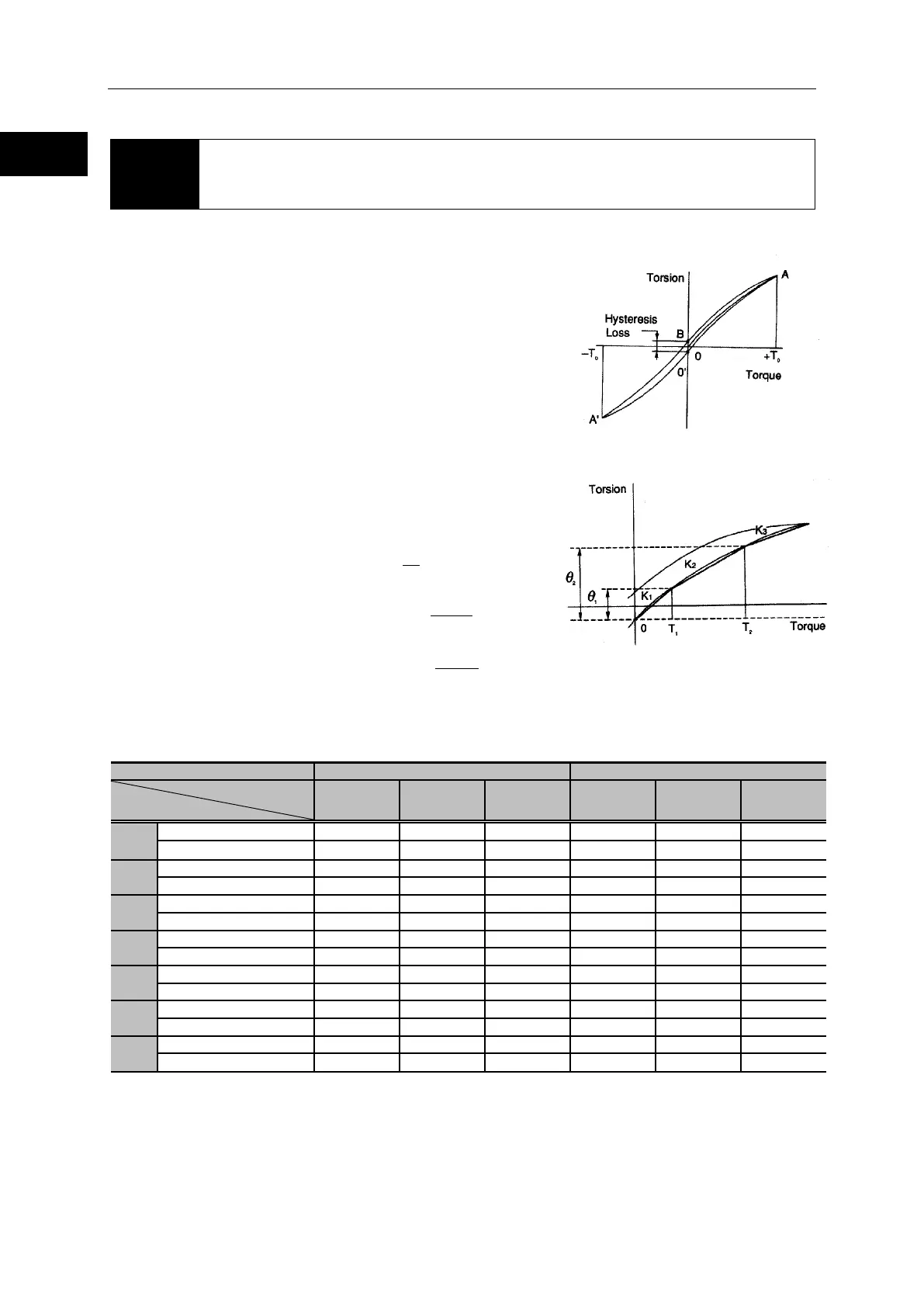

The torsional stiffness may be evaluated by dividing

torque-torsion characteristics curve into three major regions.

The spring rate of each region is expressed K

1, K2, and K3

respectively.

K

1: spring rate for torque region 0-T1

K

2: spring rate for torque region T1-T2

K

3: spring rate for torque region over T2

The wind-up for each region is expressed as follows:

wind-up for torque region 0-T

1:

wind-up for torque region T

1-T2:

wind-up for torque region over T

2:

The following table shows average values of T

1 through T3, K1 through K3, and θ1 through θ2 for

different gear ratios.

Gear ratio

Symbol

30 50 100 30 50 100

T

1

K

1

θ

1

T

2

K

2

θ

2

K

3

Loading...

Loading...