3-3 Location and installation

3-4

Installation

Since the RSF supermini series actuator is a high precision servo mechanism, great care is required

for proper installation.

Install the actuator taking care not to damage accurately machined surfaces. Do not hit the actuator

with a hammer. Take note that actuators provide a glass encoder, which may be damaged by impact.

Procedure

(1) Align the axis of rotation of the actuator and the load mechanism precisely.

Very careful alignment is required especially when a rigid coupling is applied. Slight differences

between centerlines will cause failure of the output shaft of the actuator.

When attaching a coupling, be sure not to apply force to the actuator output shaft.

(2) Fasten the flange of the actuator with flat washers and high strength bolts. Use a torque wrench

when tightening the fasteners.

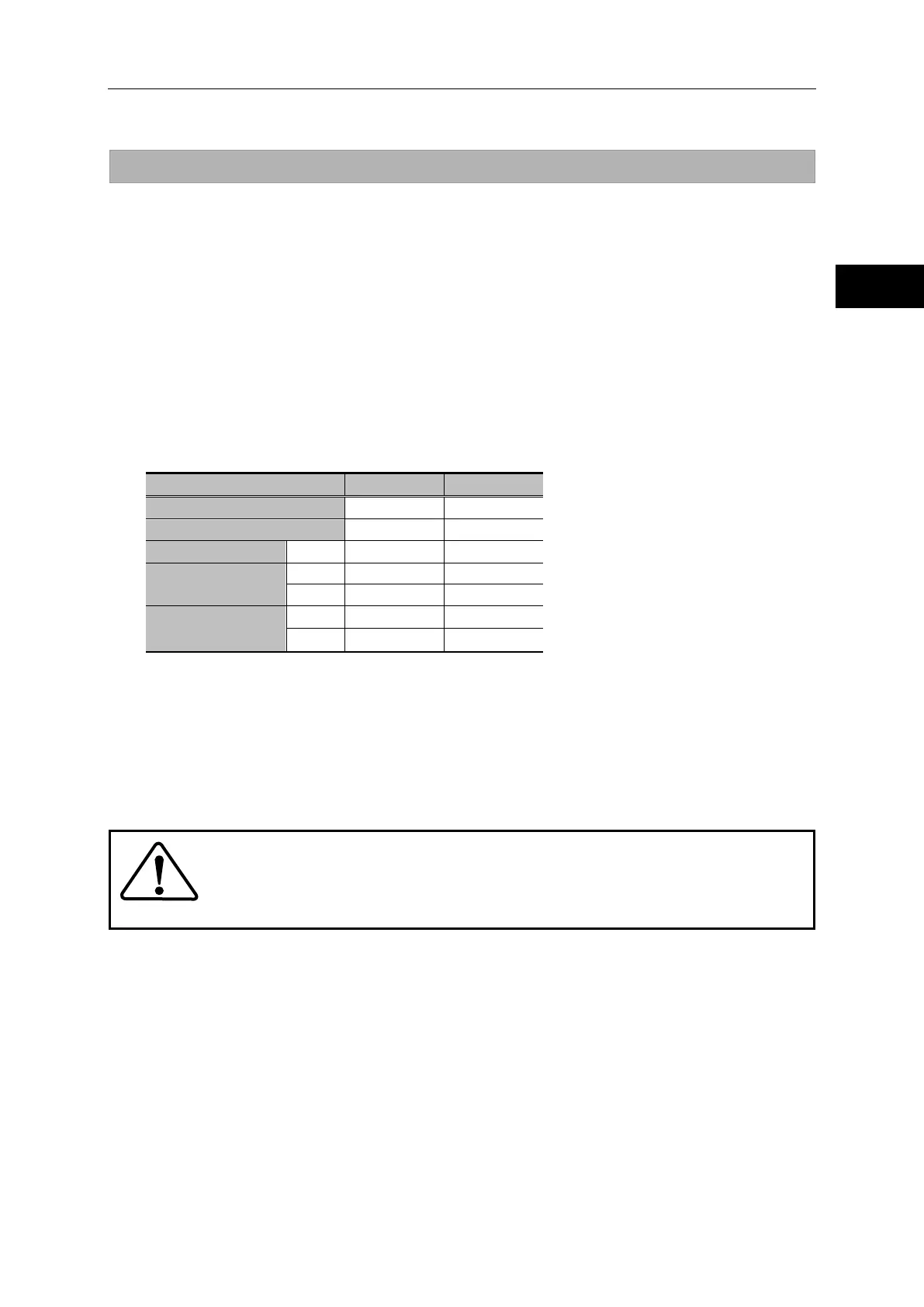

The recommended tightening torque is shown in the table below:

4 2

M1.6 M2

mm 15 25

Wrenching torque

N・m

0.26 0.25

kgf・m

0.03 0.03

Transfer torque

N・m 3.0 2.0

kgf・m 0.3 0.2

Recommended bolt: JIS B 1176 bolt with hexagonal hole; Strength category: JIS B 1051 12.9 or greater

(3) For wiring operation, refer to “AC Servo Driver for 24VDC Power Supply HA-680 Series Technical

Data.”

(4) Motor cable and encoder cable

Do not pull the cable. Do not hang the actuator with the cable. If you do, the connection part may

be damaged. Install the cable with slack not to apply tension to the actuator. Especially, do not

use the actuator under any condition where the cable is bent repeatedly.

Do not disassemble and re-assemble the actuator.

The actuator uses many precision parts. The Harmonic Drive Systems, Inc.

does not guarantee the actuator that has been reassembled by others than the

authorized persons by the Harmonic Drive Systems, Inc.

Loading...

Loading...