2-4 Duty Cycles

2-4

Selection of the RSF supermini Series

Example: 1

Select an actuator that best suits the following operating conditions:

Rotary speed: 140r/min

Load moment of inertia: 0.9×10

-3

kg・m

2

Since the load mechanism is mainly inertia, the load torque is negligibly small.

Acceleration/deceleration time is 0.03sec (30msec) or less.

(1) Compare these conditions with the [1-5 Specifications of RSF supermini actuators] (P1-4) and

temporarily select RSF-5B-50.

(2) Obtain J

A=1.83×10

-4

kg・m

2

, TM =0.9 N・m, KT=0.54 N・m/A, and IM =2.2A from [1-5 Specifications of

RSF supermini actuators] (P1-4).

(3) The friction torque of the actuator is T

F = 0.54×2.2-0.9 = 0.29 N・m from Formula (3) on the

previous page.

(4) Therefore, the shortest acceleration time and deceleration time can be obtained from Formula (1)

and Formula (2), as follows:

t

a = (0.183×10

-3

+0.9×10

-3

)×2×π/60×140/0.9 = 0.018 sec (18msec)

t

d = (0.183×10

-3

+0.9×10

-3

)×2×π/60×140/(0.9+2×0.29) = 0.011 s (11msec)

(5) Because the assumed acceleration/deceleration time is 0.03sec (30msec) or less, the temporarily

selected actuator can be used for acceleration/deceleration, based on the result of (4).

(6) If the calculation results of the acceleration/deceleration time do not fall within the desired time

range, examine them again as follows.

• Try to reduce the load moment of inertia.

• Re-examine the gear ratio and gear head model.

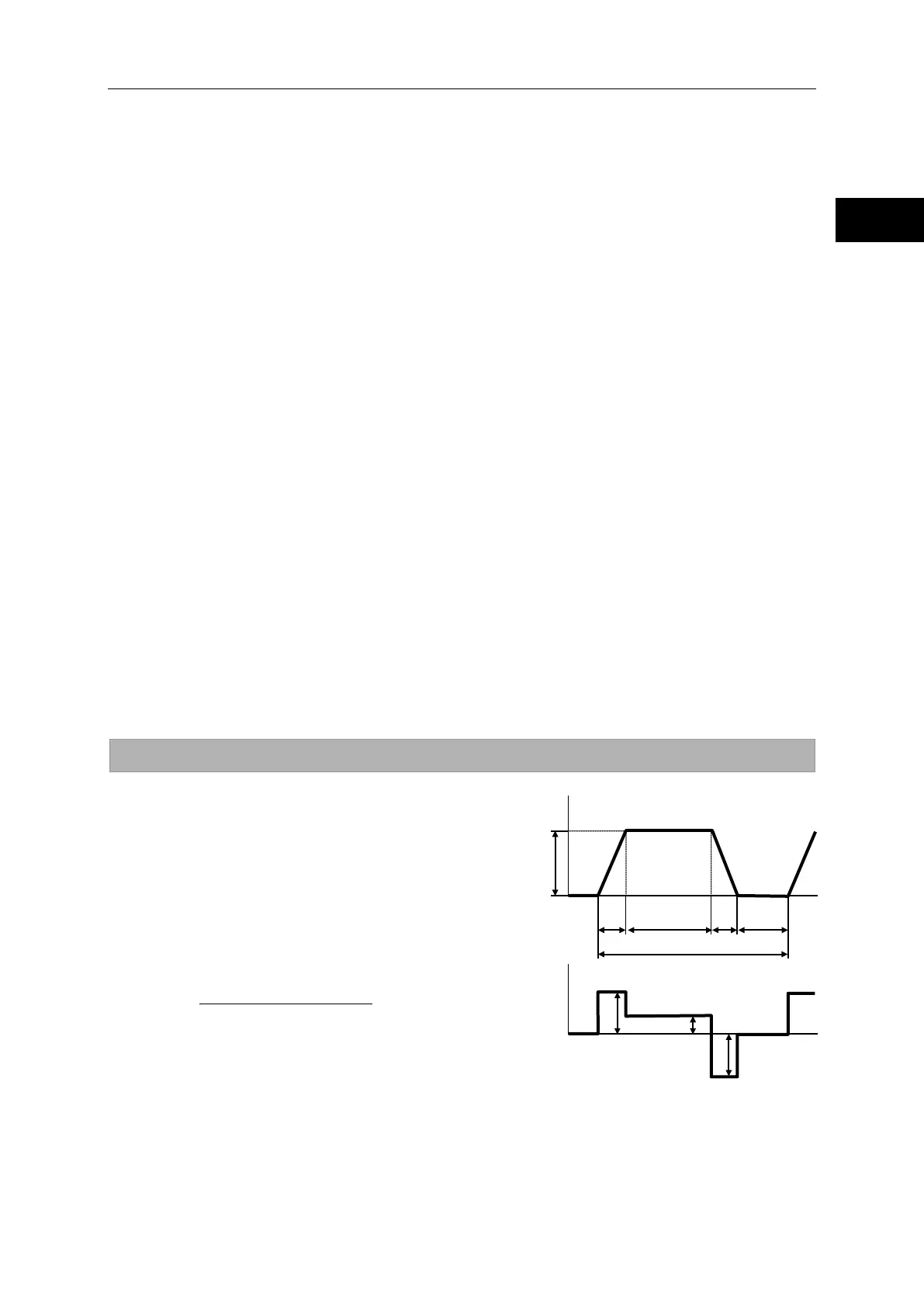

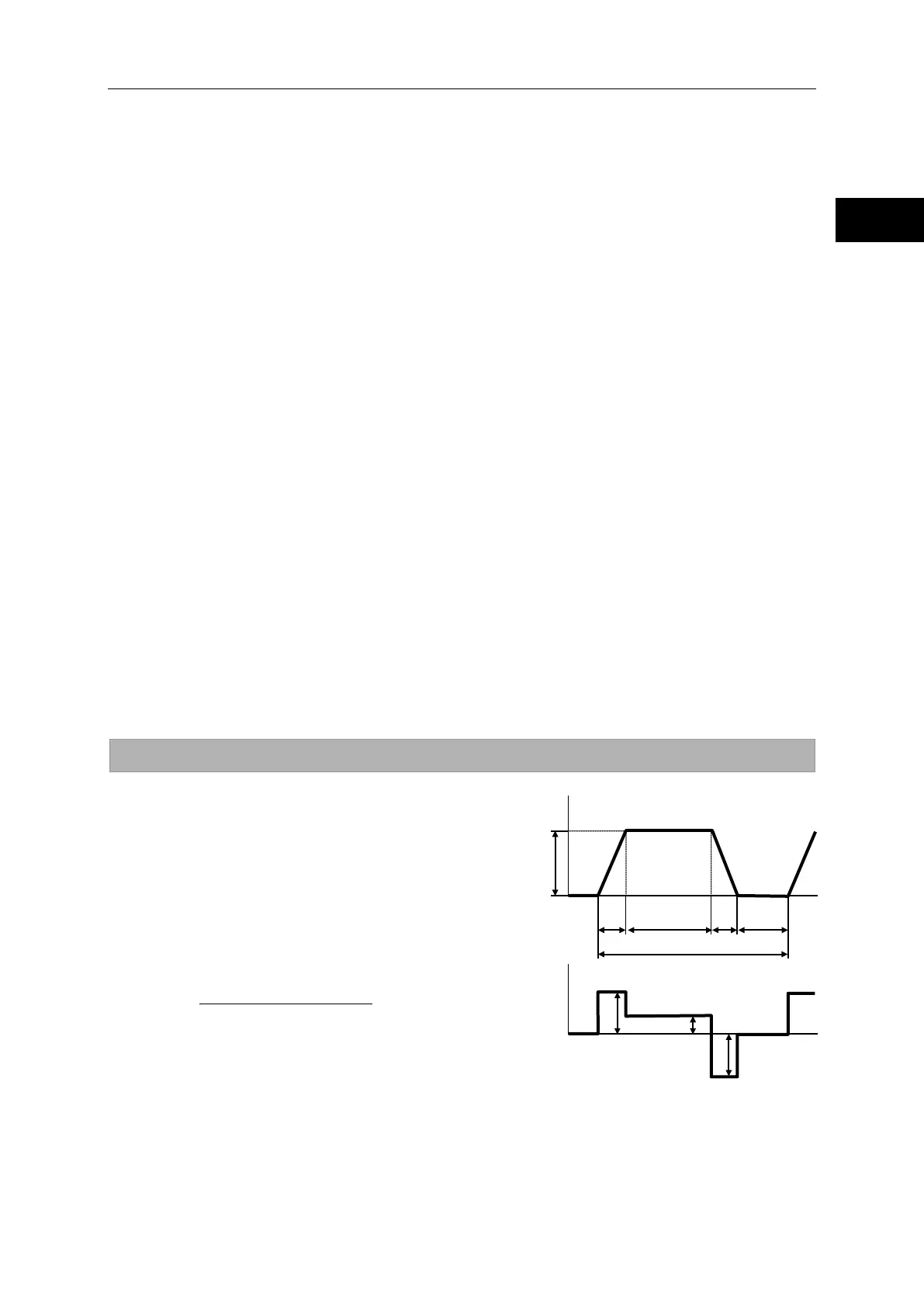

Calculating equivalent duty

During the selecting process of the RSF supermini series,

the temporal variability of torque and rotation speed need to

be taken into account. During acceleration or deceleration in

particular, a large amount of electricity flows to generate a

large amount of torque, resulting in a greater amount of

heat.

Using the following formula, calculate the duty: %ED when

the actuator is operated repeatedly in the drive pattern

shown to the right.

(4)

Acceleration time from speed 0 to N

[

]

Deceleration time from speed N to 0

[

]

Operating time at a constant speed of N

[

]

single cycle time in second

[

]

La

duty factor for acceleration time

duty factor for driving time

Ld

duty factor for deceleration time

100

t

tKtKtK

ED%

dLdrLraLa

×

×+×+×

=

Ta, Tr, Td: output torque

Loading...

Loading...