21©HBS Bolzenschweiss-Systeme GmbH & Co. KG

All rights reserved – Reprinting, in whole or in part, only with the approval of the manufacturer

9 Welding Process

9 Welding Process

Stud welding with tip ignition is divided into contact stud welding and gap stud wel-

ding. This stud welding unit may exclusively be used for contact stud welding and

gap stud welding.

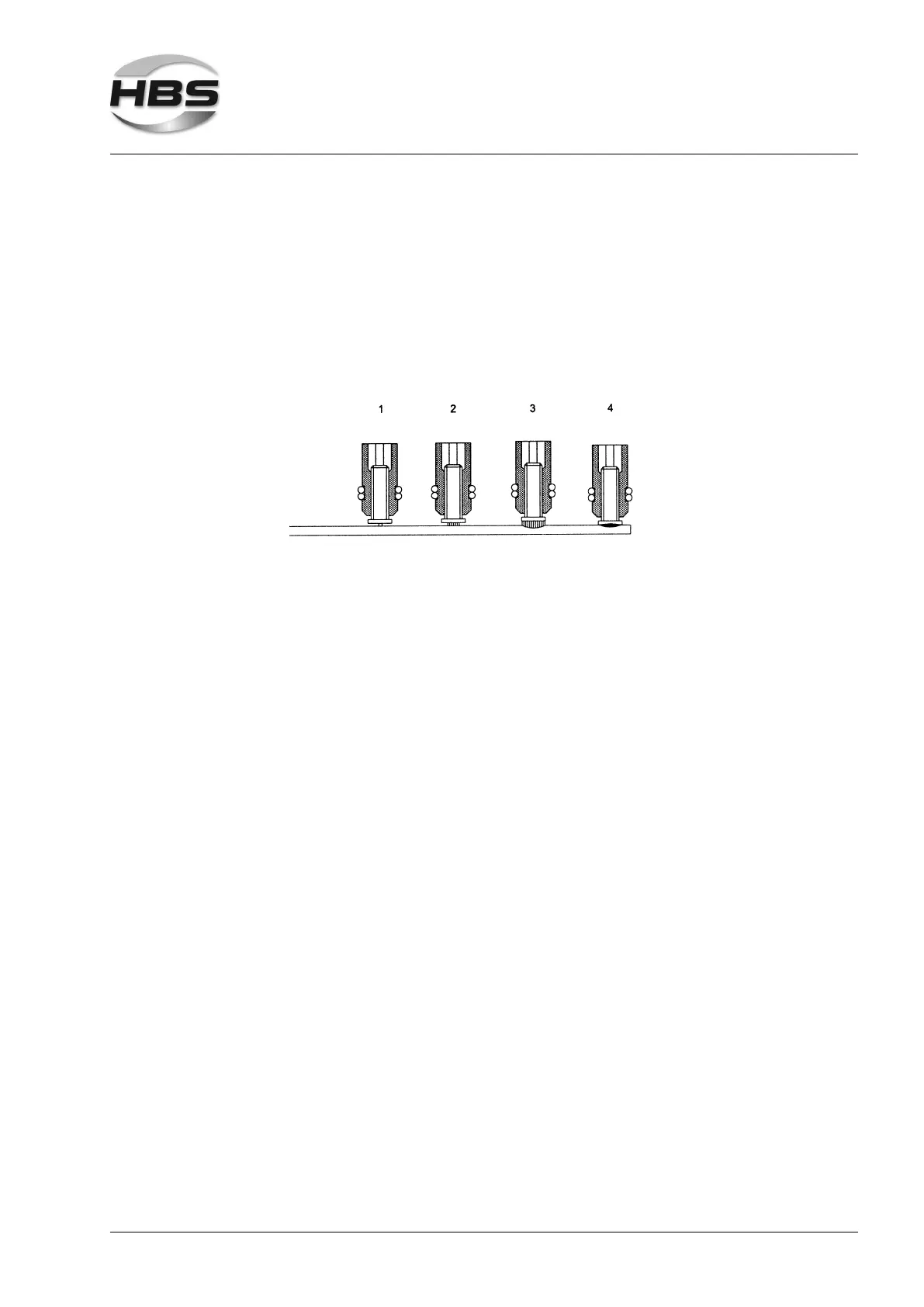

9.1 Contact Stud Welding

– The welding gun is placed onto the work piece (see gure, position 1). The wel-

ding element which projects above the welding gun support legs, is pushed back

tensioning a pressure spring.

– After positioning the welding gun against the workpiece, the operator presses

the welding gun trigger and starts the welding process; thus the current circuit is

closed.

– The capacitors of the stud welding unit are discharged. Because of the high

discharge current, the ignition tip evaporates explosion-like. The air gap between

welding element and workpiece is ionized (see gure, position 2), a light arc is

produced.

– The light arc melts the face of the welding element together with an area of the

workpiece of about the same dimension (see gure, position 3).

– Caused by the pressure spring, the welding element moves to the workpiece with

a speed of 0,5 to 1 m/s. The adjusted spring force controls the plunging speed of

the welding element.

– Higher plunging speed leads to shortened arc time and consequently to lower

welding energy with identical voltage setting.

– The light arc is cut as soon as the welding element touches the workpiece.

– Now the capacitors are short-circuited and the rest of the energy drains off (see

gure, position 4).

– The pressure spring continues to push the welding element into the weld pool.

Loading...

Loading...