©HBS Bolzenschweiss-Systeme GmbH & Co. KG

All rights reserved – Reprinting, in whole or in part, only with the approval of the manufacturer

44

13 Checking the Quality of the Weld

13 Checking the Quality of the Weld

You can check the quality of the weld by means of a visual inspection and a bending

test.

The number and type or method of the tests to be performed and the acceptance

criteria are dened in respective standards for quality demands.

13.1 Carrying out Visual Inspection

Carry out a visual inspection on all welding elements.

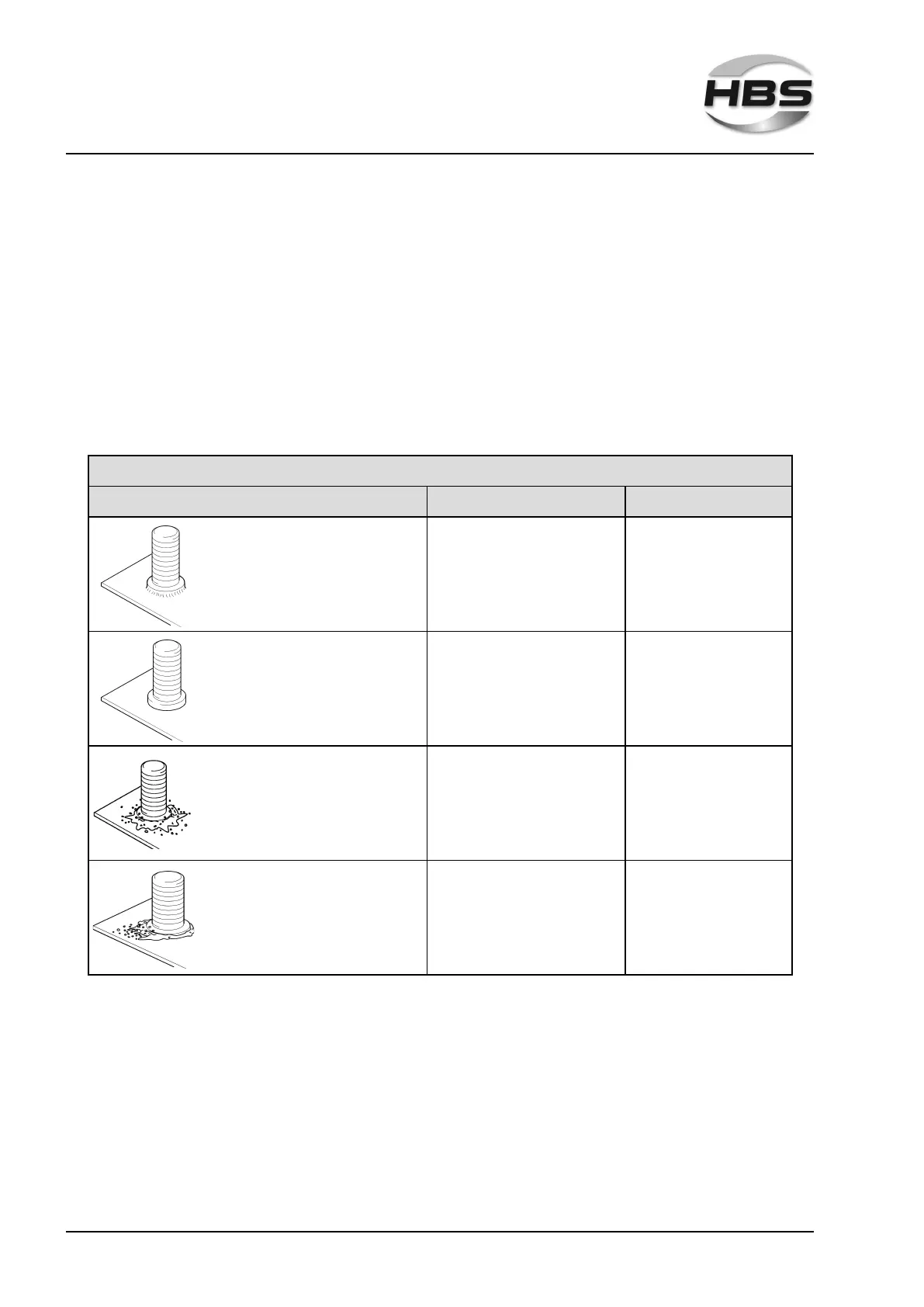

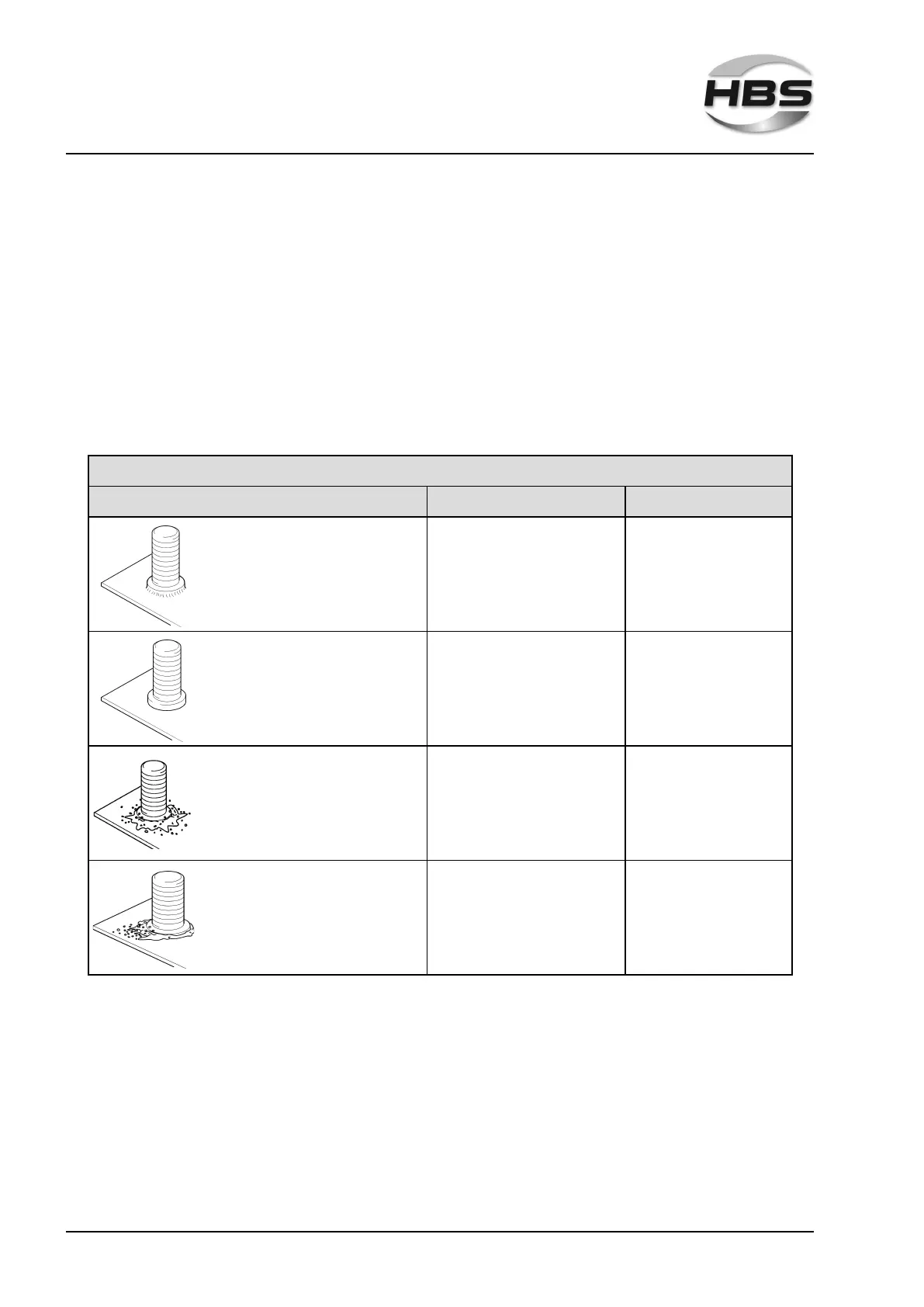

Visual Inspection

Condition Possible cause Corrective actions

Good welded joint

Low spatters around the weld without

outer aws

The weld pool forms a collar around

the ange of about 1 - 1.5 mm

Correct parameters none

Gap between ange and workpiece Weld energy too low Increase weld energy

Plunging speed too low Correct plunging speed

Insufcient support of parent

material

Provide support

Many spatters around the weld Weld energy too high Reduce weld energy

Insufcient plunging speed Increase plunging speed

One-sided weld pool

One-sided spatter collar

Effect of arc blow

Unsymmetric ground connection

Take care for symmetrical

ground connection

Weld pool came out on one side Welding gun put at an angle Put welding gun vertically to

the workpiece

Loading...

Loading...