Miscellaneous Functions | Miscellaneous functions for coordinate entries

11

472

HEIDENHAIN | TNC 620 | Conversational Programming User's Manual | 10/2017

Behavior with M92 – Additional machine reference point

Refer to your machine manual.

In addition to the machine datum, the machine tool

builder can also define an additional machine-based

position as a machine reference point.

For each axis, the machine tool builder defines the

distance between the machine reference point and the

machine datum.

If you want the coordinates in positioning blocks to be based on the

additional machine reference point, end these block with M92.

Radius compensation remains the same in blocks that

are programmed with M91 or M92. The tool length will

not be taken into account.

Effect

M91 and M92 are effective only in the blocks in which M91 and

M92 have been programmed.

M91 and M92 take effect at the start of block.

Workpiece preset

If you want the coordinates to always be referenced to the machine

datum, you can disable the setting of presets for one or more axes.

If presetting is inhibited for all axes, the control no longer displays

the SET PRESET soft key in the Manual operation mode.

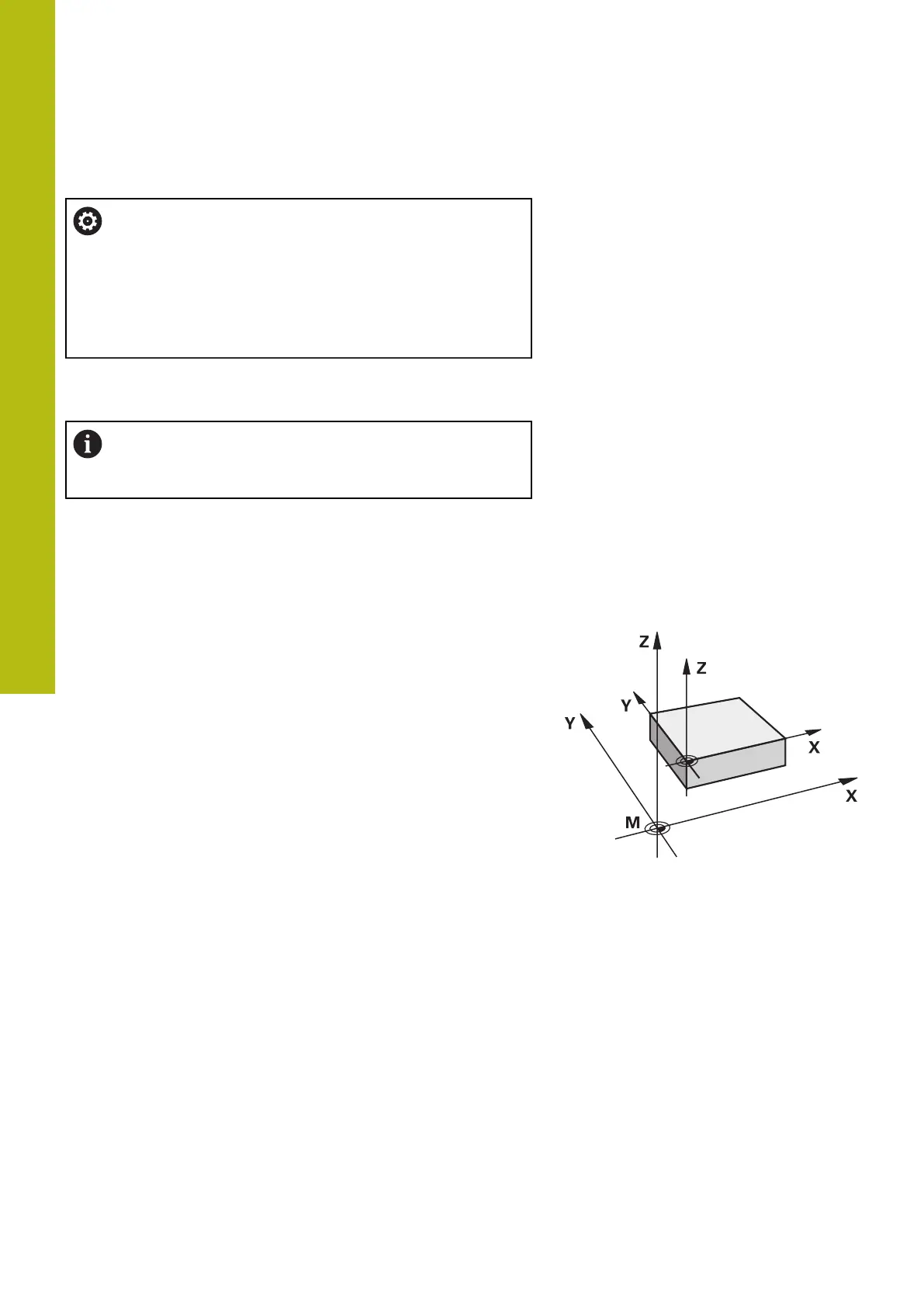

The figure shows coordinate systems with the machine and

workpiece datum.

M91/M92 in the Test Run mode

In order to be able to graphically simulate M91/M92 movements,

you need to activate working space monitoring and display the

workpiece blank referenced to the defined preset.

Further information: "Showing the workpiece blank in the working

space (option 20)", page 710

Loading...

Loading...