Tables and Overviews | Functions of the TNC 620 and the iTNC 530 compared

20

HEIDENHAIN | TNC 620 | Conversational Programming User's Manual | 10/2017

813

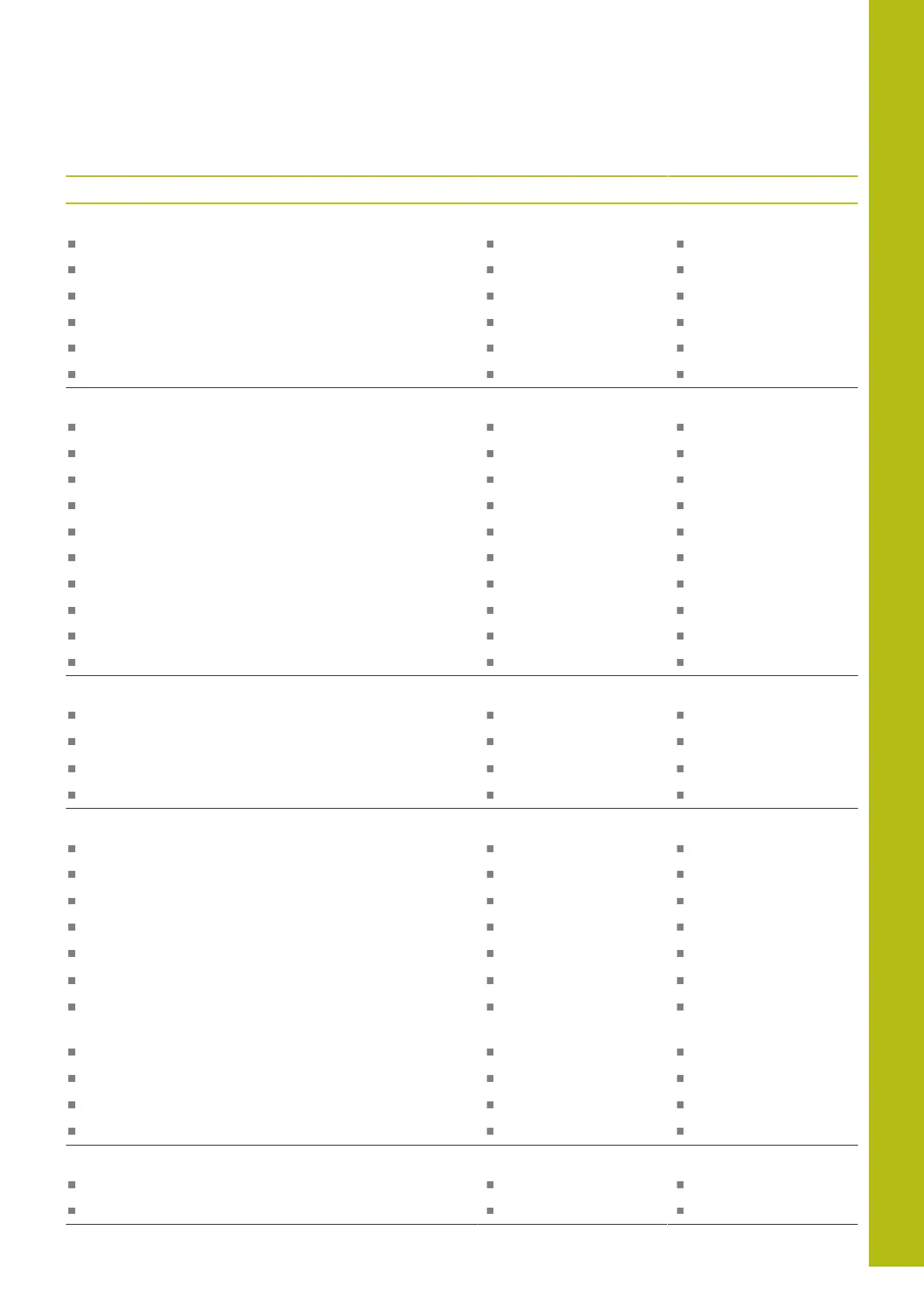

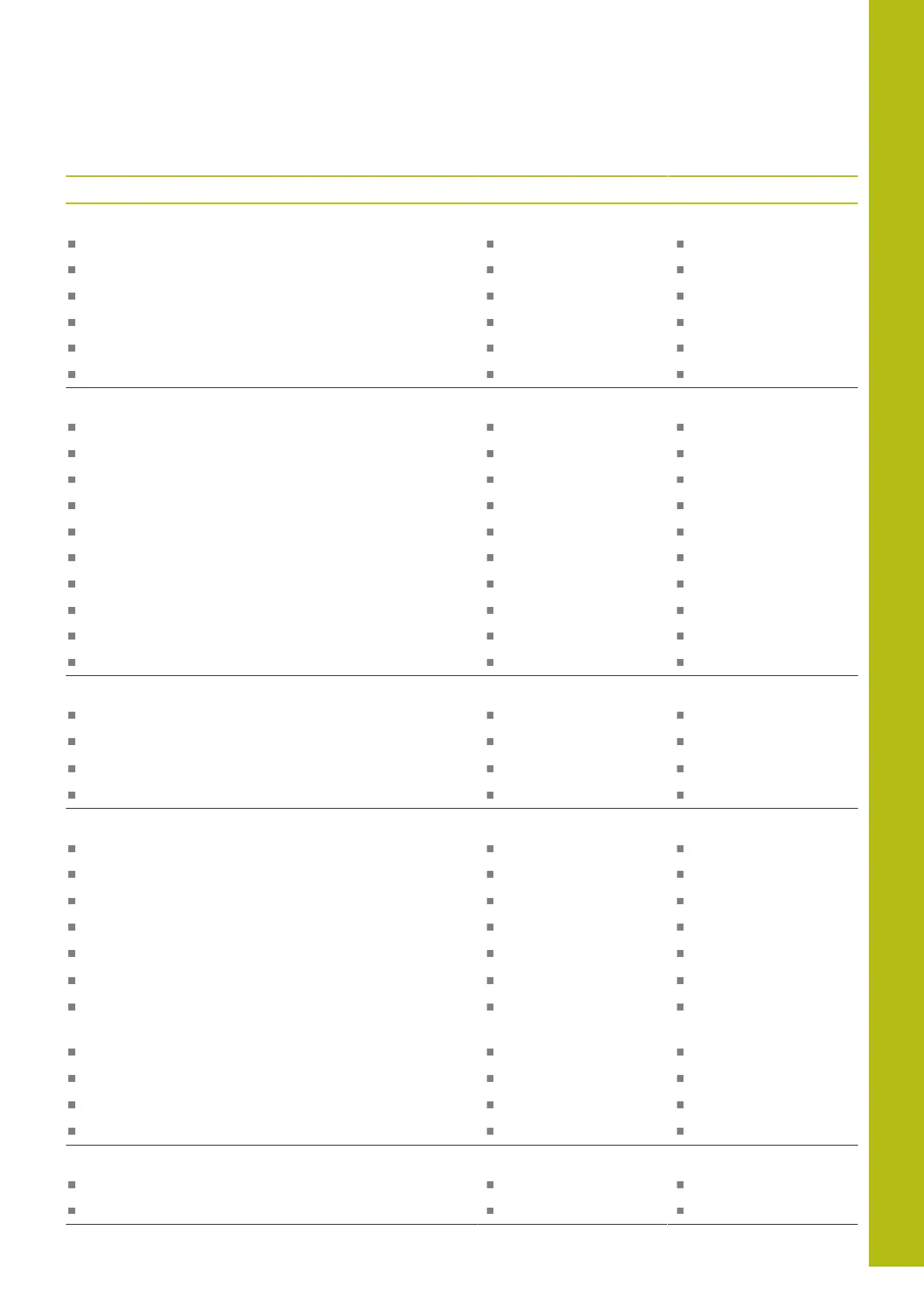

Function TNC 620 iTNC 530

CAM support:

Loading of contours from DXF data X, option 42 X, option 42

Load contours from Step data and Iges data X, option 42 –

Loading of machining positions from DXF data X, option 42 X, option 42

Load machining positions from Step data and Iges data X, option 42 –

Offline filter for CAM files – X

Stretch filter X –

MOD functions:

User parameters Config data Numerical structure

OEM help files with service functions – X

Data medium inspection – X

Load service packs – X

Setting the system time X X

Specify the axes for actual position capture – X

Definition of traverse range limits X X

Restricting external access X X

Configure counter X –

Switching the kinematics X X

Calling fixed cycles:

With M99 or M89

X X

With CYCL CALL

X X

With CYCL CALL PAT

X X

With CYC CALL POS

X X

Special functions:

Create reverse program – X

Datum shift with TRANS DATUM

X X

Adaptive Feed Control AFC – X, option 45

Define the counter with FUNCTION COUNT

X –

Define the dwell time with FUNCTION FEED

X –

Define the dwell time with FUNCTION DWELL

X –

Determine the integration of the programmed

coordinates with FUNCTION PROG PATH

X –

Defining cycle parameters globally with GLOBAL DEF

X X

Pattern definition with PATTERN DEF

X X

Definition and processing of point tables X X

Simple contour formula CONTOUR DEF

X X

Functions for large molds and dies:

Global program settings (GS) – X, option 44

Expanded M128: FUNCTION TCPM

X X

Loading...

Loading...