35

● Thoroughly flush all water pipelines before

installation, ensure no foreign matter before use.

Note that do not flush any foreign material into

plate heat exchanger.

● Apply good sealant to seal joint and the joint

must bear pressure and temperature of system.

●

If water pipes of different material are used,

ensure they are isolated, preventing electrical

conduction and corrosion.

(6) Water treatment and water quality control

● Confirm with water treatment company that

antifreezing solution, scale inhibitor, corrosion

remover that are used in water treatment do not

corrode stainless steel and copper products

before use. When system links with water tank,

to avoid domestic hot water contaminated by coil

leakage, antifreezing solution, scale inhibitor,

corrosion remover are not allowed to use.

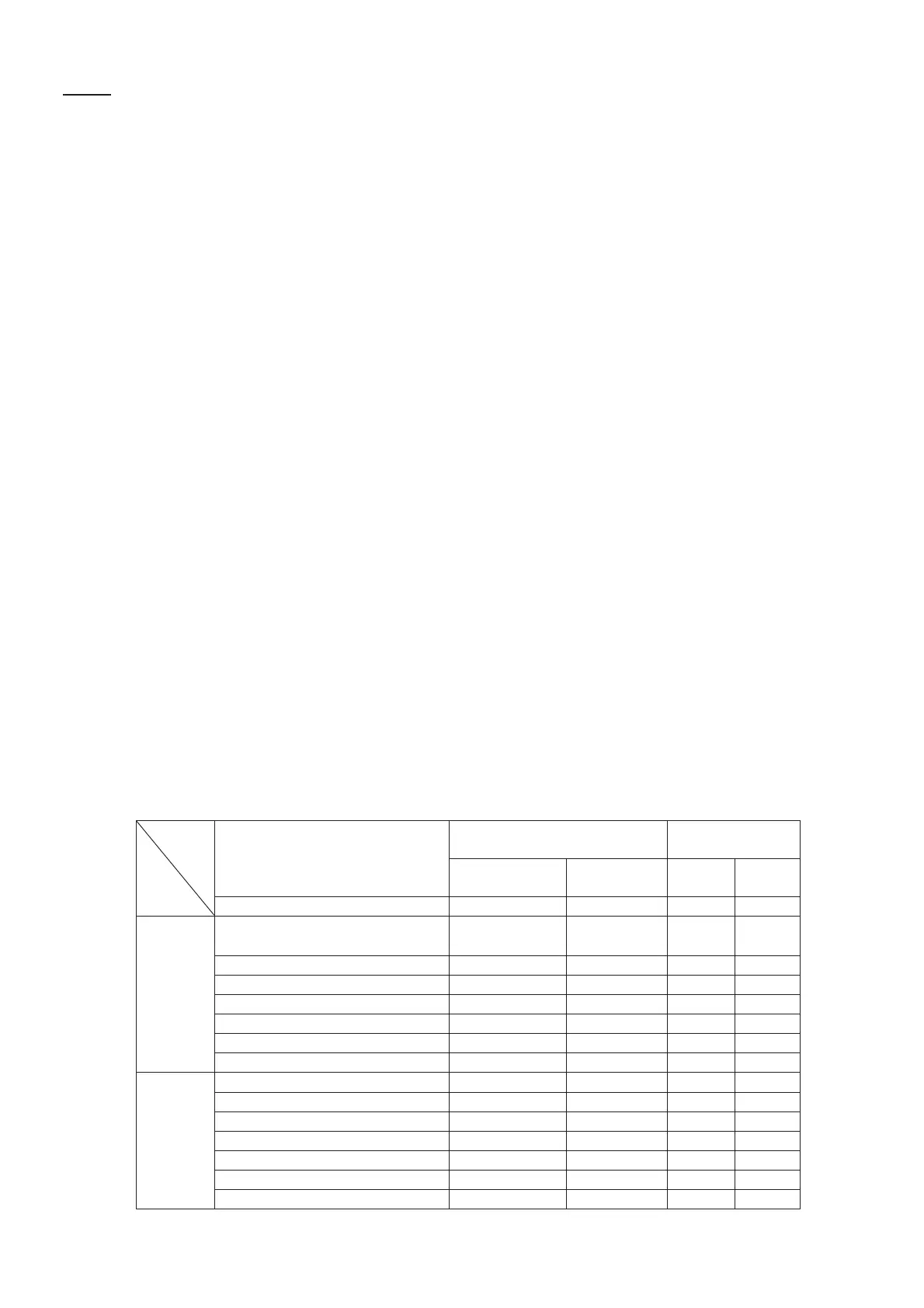

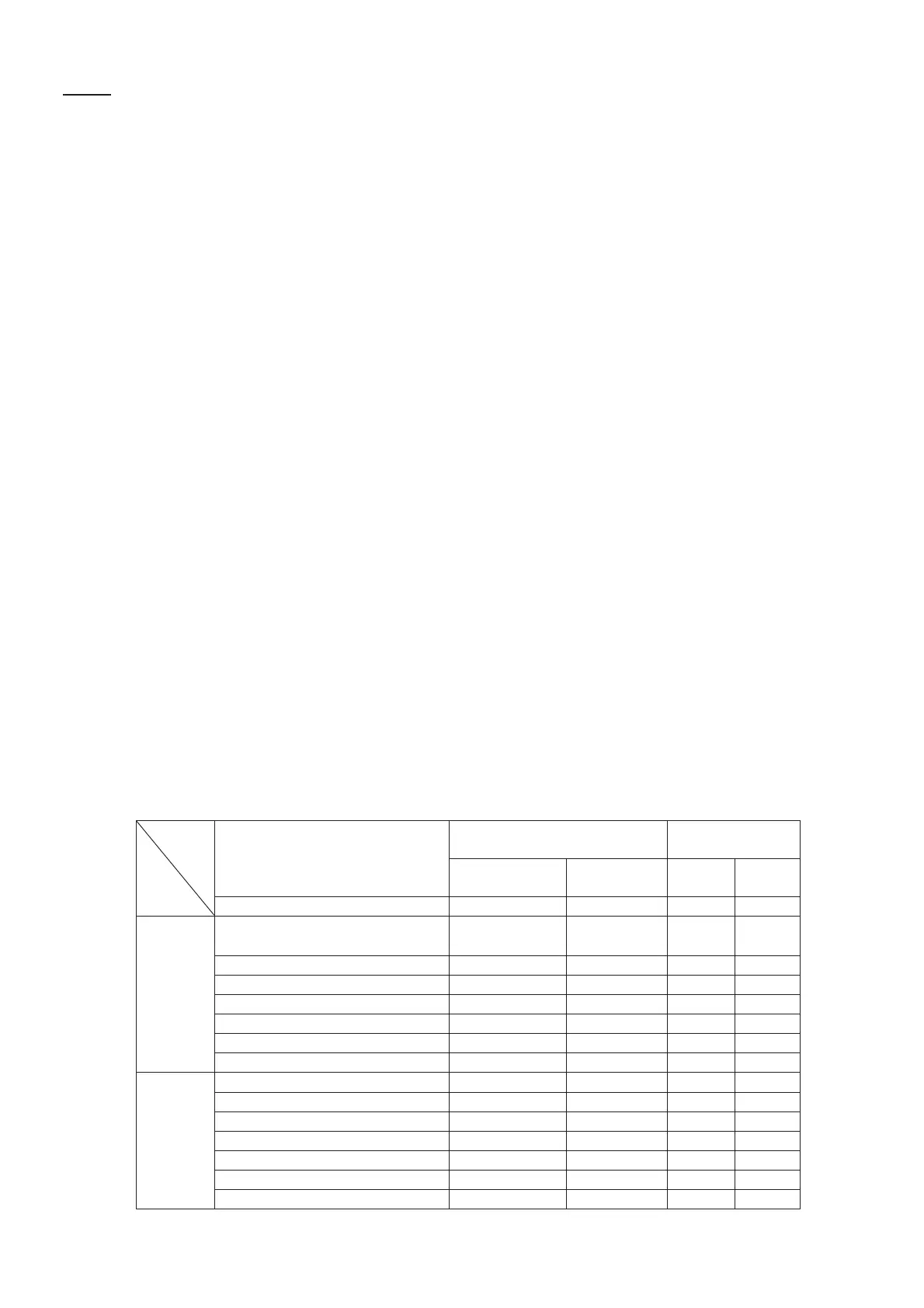

● Water quality control methods and reference

refer to water quality requirements issued by

Japan Refrigeration and Air Conditioning

Industry Association (JRA-GL-02-1994). Medium

and low water temperature reference values of

water module unit are seen in table 8.1.

Table 8.1 Benchmark of Medium and Low Water T

emperature and Make-up Water Quality (Reference Value)

Medium and Low Water

Temperature System

Tendency

Item

Circulation water

20ºC<T<60 ºC

Make-up water Corrosin Scale

PH (25 ºC) 7.0 to 8.0 7.0 to 8.0 √ √

Electroconductibility(mS/m) (25 ºC)

<30 <30 √ √

Chloridion(mgCI

-

/L) <50 <50 √

Sulfion (mgSO

4

2-

/L) <50 <50 √

Acid consumption(PH4.8)(mgCaCO

3

/L) <50 <50 √

Total hardness (mgCaCO

3

/L) <70 <70 √

Calcium hardness (mgCaCO

3

/L) <50 <50 √

Standard

Items

Ionic state silicon(mgCaSiO

2

/L) <30 <30 √

Iron (mgFe/L)

<1.0 <0.3 √ √

Copper (mgCu/L) <1.0 <0.1 √

Sulfion (mgS

2-

/L) Undetermined Undetermined √

Ammonia ion mgNH

4

+

/L) <0.3 <1.0 √

Chlorine residue (mgCI/L) <0.25 <0.3 √

Free carbon dioxide (mgCO

2

/L) <0.4 <4.0 √

Reference

Items

Stability index - - √ √

(5) Basic requirements for operating water pipe:

●

Let the end of pipe face downward when

deburring, avoiding foreign matter invading into

pipe.

● Flexible joint should be used between water

module interface and on-site pipeline, avoiding

vibration propagation and pipeline breakage.

●

Arrange drainage interface at low positions in

water system, make water in water module and

pipeline smoothly drained out. Arrange air

exhaust device at high positions. Do not treat air

vent valve and drainage interface thermally for

repair convenience.

(4) Notes for connecting water pipe

● A small amount of water may exist in water

module. Note that when sealing cap is opened.

●

Pay attention to connection location of pipe. Do

not connect water inlet and water outlet pipe

inversely.

●

Use water pipe conforming to specification.

Dimension of water pipe is equal to or above

interface dimension in machine (G1/1/4”). For main

connecting pipeline, recommend using DN40

water pipe to reduce pressure loss in pipeline.

●

Properly keep water pipe thermal insulated and

avoid pipeline freezing.

● Regularly clean water filter.

●

Pipe and pipe joint in water module should be

easy to remove and convenient to operate and

clean.

● Galvanized parts that may cause corrosion in

water system are prohibited.

●

Water pipe and pipe joint must be supported

independently on water module.

NOTE:

Be sure to install the water strainer horizontally

on the water inlet side. In case the water ow

downwards, vertical installation is allowed.

Loading...

Loading...