38

M4

1.0

M5

2.0

2.4

N·m

M6

4.0

5.0

N·m

M7

9.0

11.0

N·m

M8

18.0

23.0

N·m

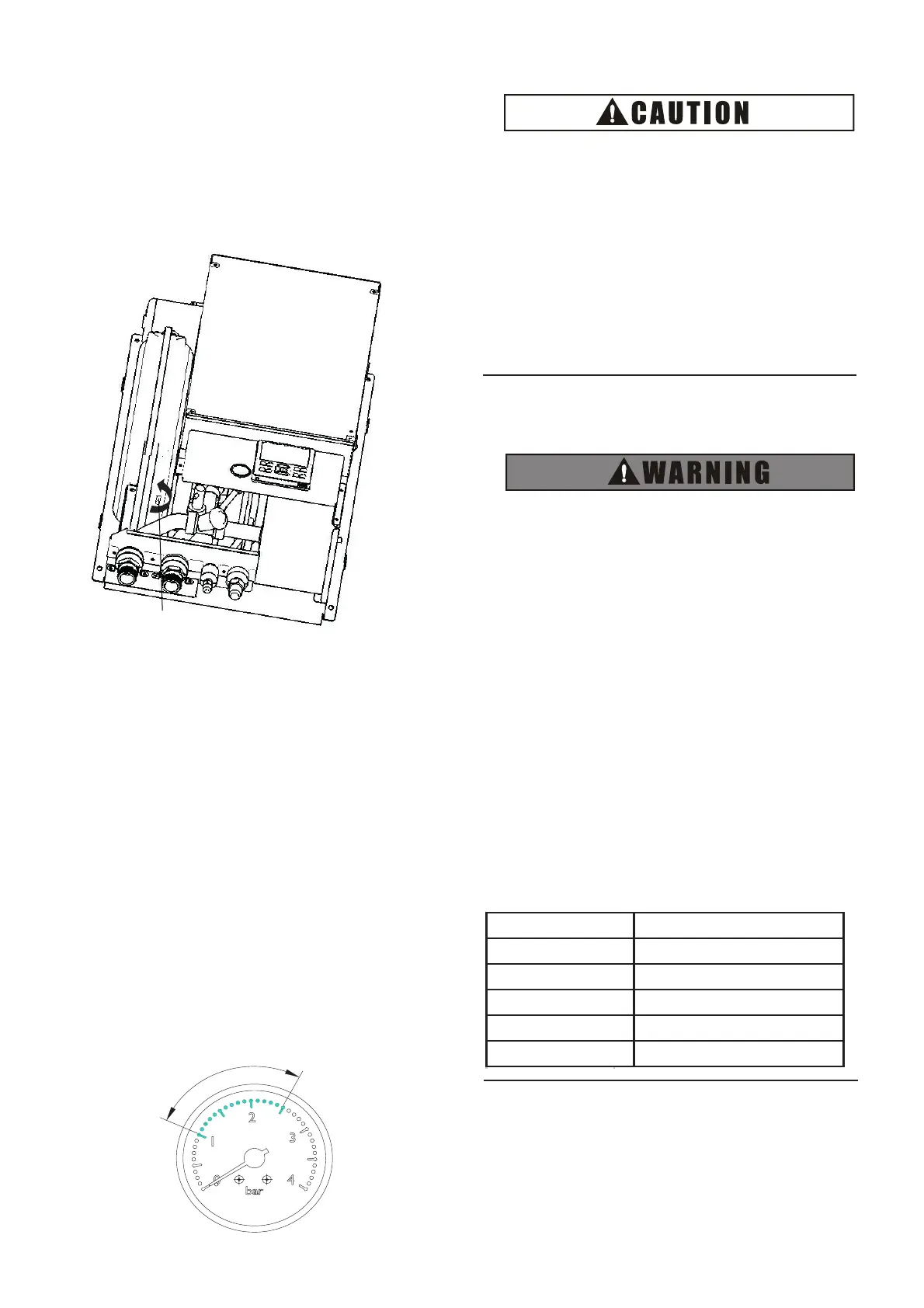

9.3 Adjust Initial Pressure of Expansion

Tank

(1)Only use dry nitrogen to adjust default initial

pressure of expansion tank when changed.

(2) Improper adjustment of initial pressure will lead to

system malfunction. Initial pressure must be only

adjusted by professional service staff.

9.4 Inject Water

(1) If system is mounted with water make-up inlet, you

can directly supplement water through this inlet. If

not mounted, you can supplement water through

make-up port in ball valve (refer to the section

6.2 Main Parts).

(2) Ensure automatic vent valve is opened (rotate two

circles at least).

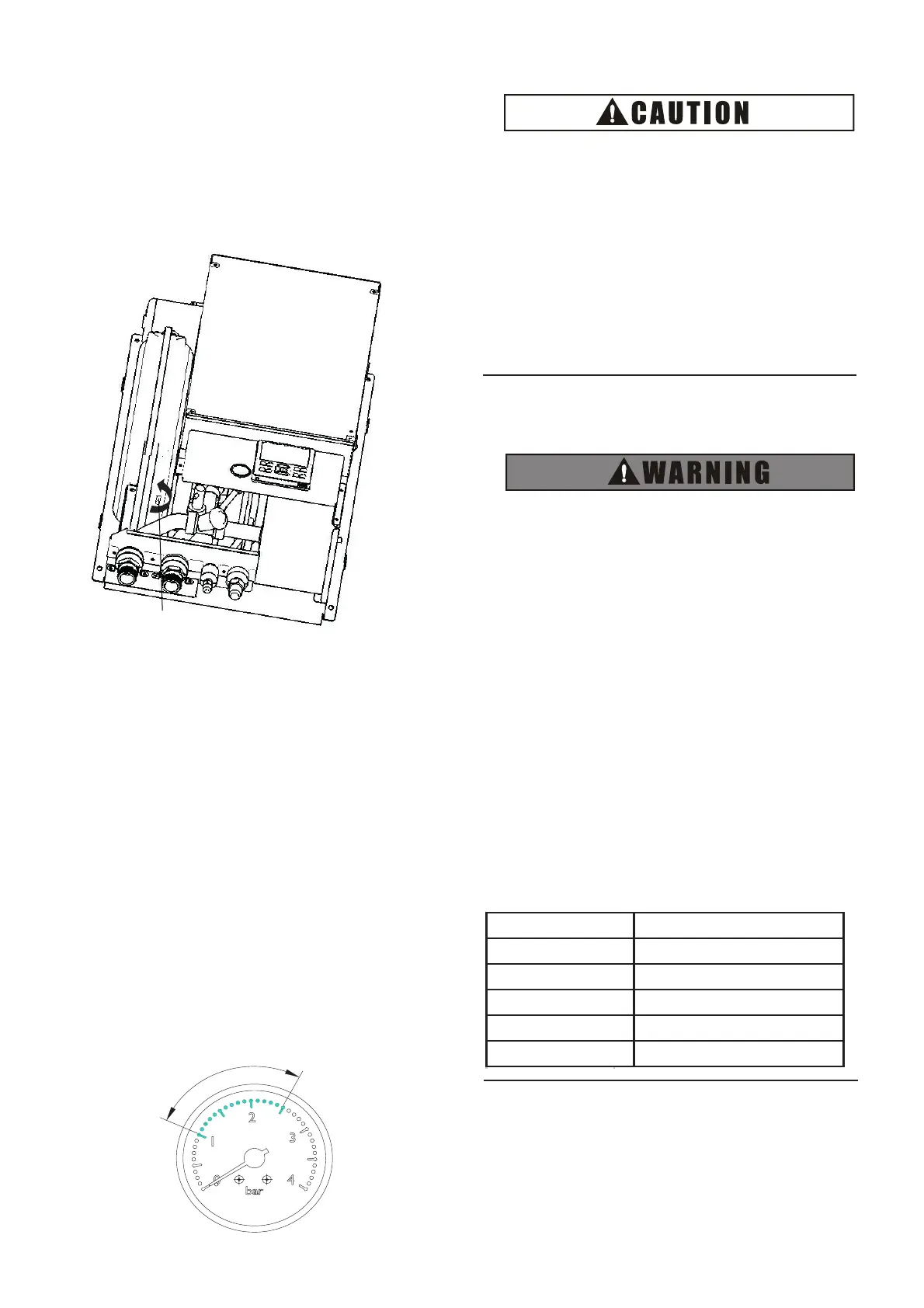

(3) Supplement water until pressure in pressure gage

is approx. 0.2MPa. The water pressure zone of

unit working normally sees below. If pressure of

tap water on site is lower than 0.2MPa, adopt

booster pump to increase pressure up to

0.2MPa. Discharge air from system using vent

valve as far as possible.

(4) Open safety valve, check whether water is drained

normally when water pressure is too high.

Rotate Cap in the B ottom in

Anticlockwise Way, Y ou Can See Thimble.

Normal Pressure Z one

●

●

Water pressure in pressure gage varies with

water temperature. However, water pressure

should maintain above 0.1 MPa, avoiding air

invasion. When lower than 0.2 MPa, manually

supplement water into system.

● When water pressure is too high, the unit will

drain some water through safety valve.

10. Wiring

● Cut off main power supply in water module and

outdoor unit for more than 3 minutes before

wiring or regular check.

● Ensure fan in outdoor unit stops before wiring or

regular check.

●

●

●

● Avoid electrical wire, refrigerant pipeline, metal

plate edge and electrical component inside

machine contacts each other, otherwise, it may

damage electrical wire and lead to fire.

● Apply ELB with medium induction speed. If not

used, it may lead to electric shock or fire.

● Tighten screws following the torques below:

Screw specification Torque range

1.3 N·m

to

to

to

to

to

●

water temperature. However, water pressure

should maintain above 0.1 MPa, avoiding air

invasion. When lower than 0.2 MPa, manually

supplement water into system.

drain some water through safety valve.

● When water pressure is too high, the unit will

● Cut off main power supply in water module and

outdoor unit for more than 3 minutes before

wiring or regular check.

● Ensure fan in outdoor unit stops before wiring or

regular check.

●

●

●

● Avoid electrical wire, refrigerant pipeline, metal

plate edge and electrical component inside

machine contacts each other, otherwise, it may

damage electrical wire and lead to fire.

● Apply ELB with medium induction speed. If not

used, it may lead to electric shock or fire.

● Tighten screws following the torques below:

When injecting water, it can not discharge all of

air from system. Residual air can be discharged

through automatic vent v

alv

e in first running

several hours of system. Extra water may be

inj

ected regarding water pressure

attenua

ti

on .

Protect wires, drainage pipe and electrical

apparatus, avoiding damage by mouse and other

animals. If they are not protected, the mouse may

bit unprotected apparatus and lead to fire.

Wrap electrical wire with adhesive tape and seal

electrical connection, preventing condensation

and insect invasion.

Fasten electrical wire tightly of water module by

string.

Loading...

Loading...