φ 9.53 40

φ 12.7 60

34

Right

Wrong

Seal with Adhesive Tape or Sealing Cap

Do not put pipe down on the ground

8. Refrigerant and Water Pipe

R410A refrigerant is adopted. When leakage and air

tight test are made, do not mix with oxygen,

acetylene, inflammable gas and poisonous gas. They

are very dangerous and may cause explosion.

Recommend using compressed air, nitrogen or

refrigerant.

8.1 Refrigerant Pipeline and Piping

(1) Copper pipe are prepared on site.

(2) Pipe dimension are selected as follows.

Unit (mm)

(3) Select copper pipe without dust and moisture.

Blow dust and impurity in pipeline with nitrogen or

dry air before pipeline is mounted.

8.2 Connect Refrigerant Pipeline

(1) Confirm stop valve is closed. Gas and liquid pipe

are located as shown in Fig.8.1:

(2) As shown in Fig.8.2, screw up nut cap. Refer to

the torque required below:

Water

Inlet

Water

Outlet

Gas

Pipe

Liquid

Pipe

Fig.8.2 Screw up Nut Cap

Pipe Diameter

Torque(N•m)

(3) Heat preservation of refrigerant pipe

After pipe is connected, heat preservation

material on site should be used to keep gas pipe,

liquid pipe and connecting nut warm, and wrap

the pipe with adhesive tape, avoiding heat

dissipation condensation on surface of pipeline.

●

When the pipe passes through holes, pipe head

should be sealed by sealing cap.

●

Seal the pipe end with sealing cap or adhesive

tape. Do not directly put pipe down on the ground.

(4) Charging and discharging of refrigerant

Operate according to installation and maintenance

manual of outdoor unit.

8.3 Connect Water Pipeline

(1) The connecting location of water pipeline is seen

in Fig.8.1.

(2) Install ball valve

There are two ball valves provided with the unit.

For convenience of repair and maintenance, install

the ball valves on water inlet and outlet pipes

of water module. Installation location refers to the

section 6.2 Main Parts.

● When ball valve is mounted, rubber gasket must

be mounted (accompanied with the unit),

otherwise water leakage may be caused.

●

Note the location of ball valve, and the direction of

ball valve and drain valve, which are essential to

maintenance.

● Screw up ball valve by using two wrenches.

R410A refrigerant is adopted. When leakage and air

tight test are made, do not mix with oxygen,

acetylene, inflammable gas and poisonous gas. They

are very dangerous and may cause explosion.

Recommend using compressed air, nitrogen or

refrigerant.

Type

Gas pipe Liquid pipe

Φ 15.88

Φ 9.53

AHM-080FJFAA

AHM-160FJFAA

Fig.8.1 Location of Refrigerant and Water Pipeline

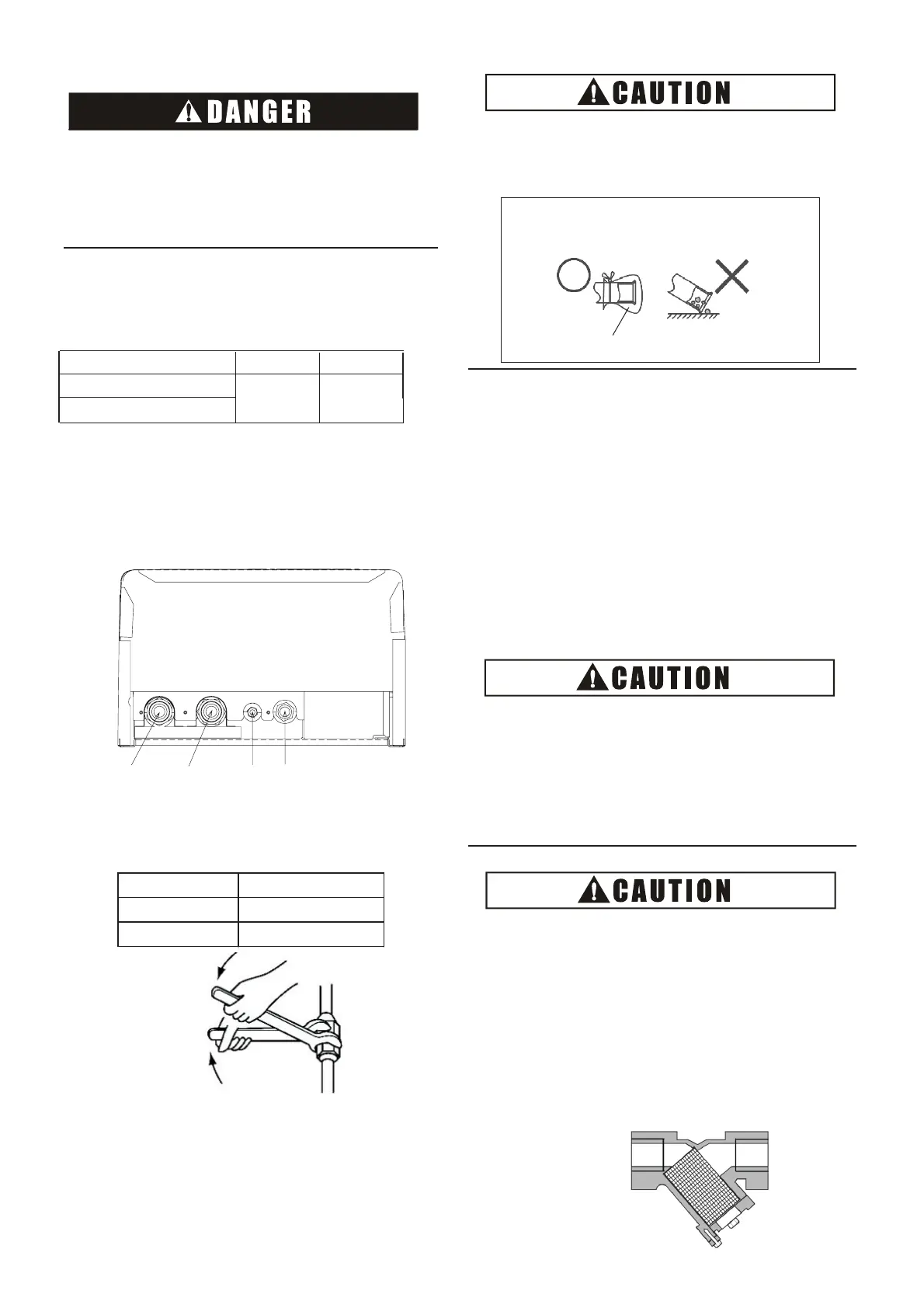

(3) Additional water strainer

●

Provide a 50 mesh or more water strainer at the

water inlet side of water piping. Otherwise, damage

to the plate heat exchanger may occur. In the plate

heat exchanger, water flows through a narrow space

between the plates.Therefore, there is a possibility

that freezing or corrosion may occur if foreign

particles or dust clog the flow of water between the

plates.

Water Strainer

(50 mesh or more recommended)

This is not required when cooling function is not used.

Water Flow Direction →

Loading...

Loading...