54

reset button

3.2 Safety Device

●

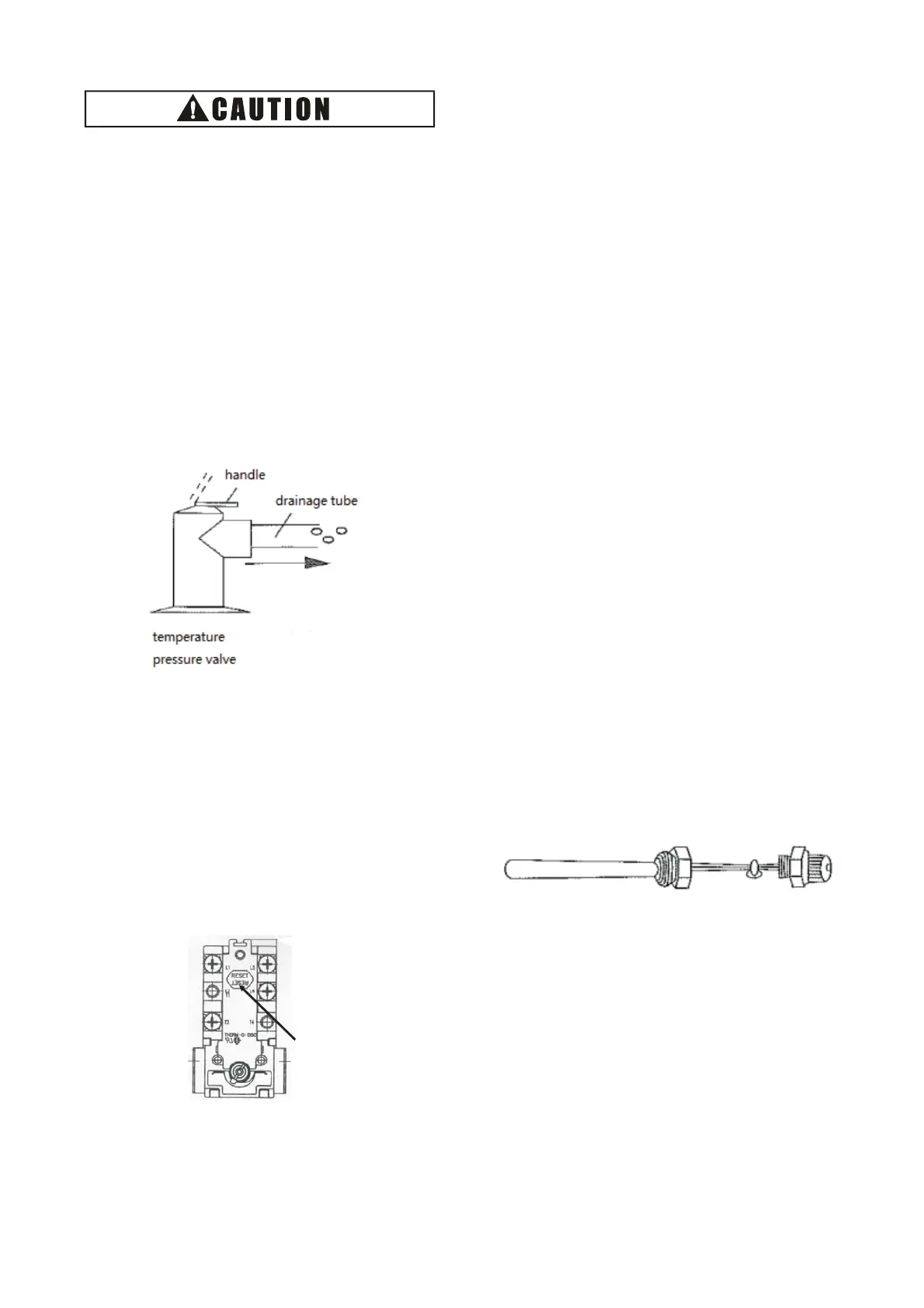

Temperature pressure valve must be tightly

connected with drainage pipe. Drainage pipe

must be connected as shown in Fig.3.3 and

introduced to building downcomer (The water

temperature in drainage pipe may be high, note

burns).

● Temperature pressure valve in water tank can

not be connected for other purposes.

● Check temperature pressure valve once half a

year. When checking, open temperature

pressure valve handle (seen below),

temperature pressure valve will smoothly drain

water out. The water temperature may be high,

note burns. Reset after it is errorless. If drainage

fails, contact local dealer for repair.

●

Temperature pressure valve and its drainage

pipe must keep smooth and not blocked.

● Do not install electric heating without protective

device.

●

Temperature protection device: Water tank

electric heating has temperature protection

device. When temperature is high, temperature

switch will power off . Power will restore

automatically when temperature is lower than

75ºC.

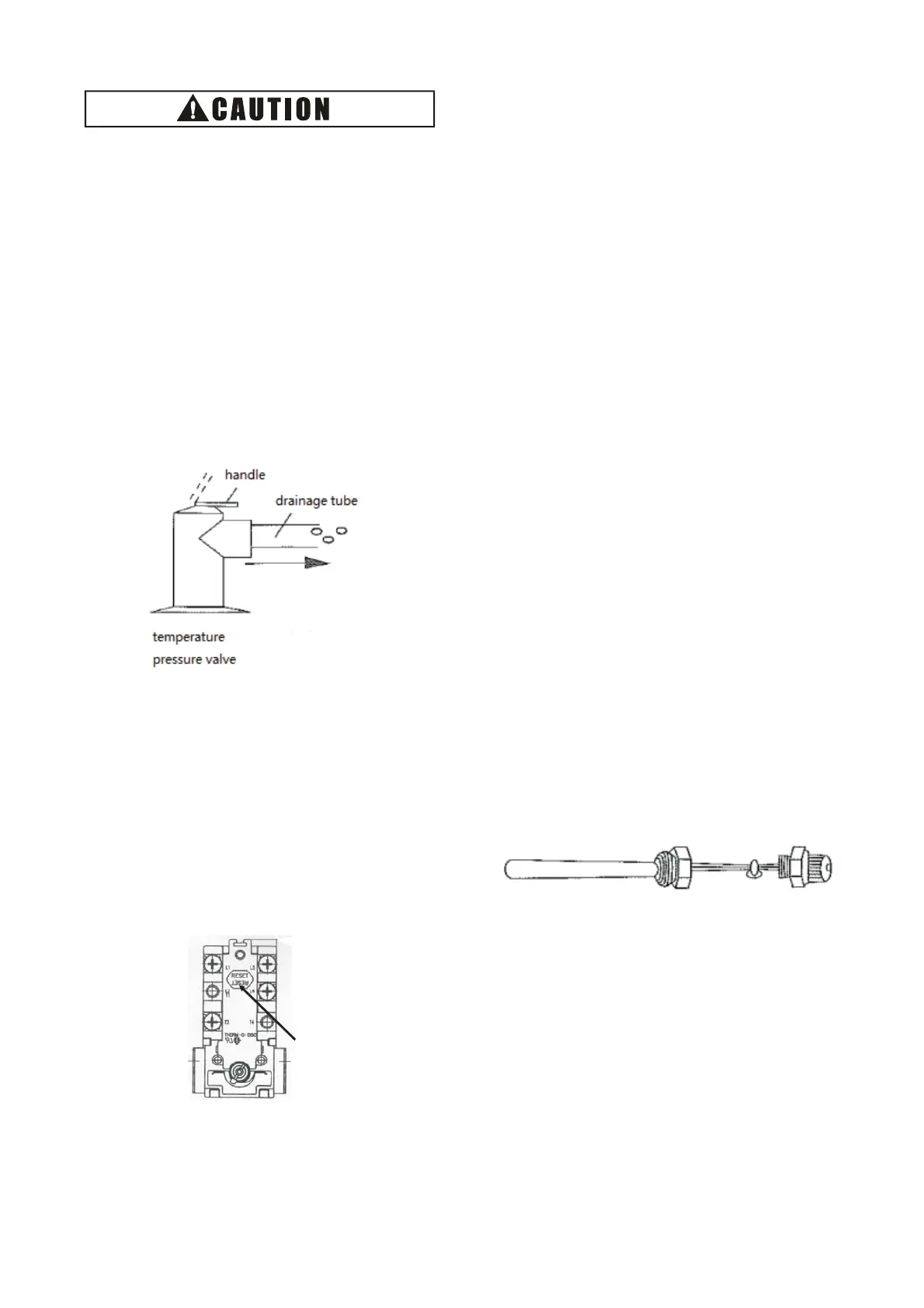

● Temperature protection device cuts off electric

heating power at high temperature. After

disconnected, open electrical box cover and

press red button to reset temperature protection

device. Location of red button is seen below:

● Electrical box cover must be opened by

qualified electrician.

●

Power off before open electrical box cover.

● Temperature pressure valve is used to prevent

too high temperature in water tank (>94ºC) and

water pressure (>0.85MPa).

3.3 Installation Guide

Note when water tank is installed:

● Recommend installing this equipment to balcony

or outdoor at temperature from 0ºC to 43 ºC .

● Water tank is mounted near floor drain to

connect temperature pressure valve drainage

tube.

● Do not install water tank in place with corrosive

gas.

● Installation location is free from frosting.

● Installation location must bear weight of water

tank containing water.

●

Ensure dimension of water pipe is above 1 inch

(recommend DN40 water pipe), provide enough

capacity to pipeline and reduced resistance in

pipeline system.

● Water tank is located in a place that is

convenient for repair and ensuring electrical box

opened. Refer to Fig.3.1-2.

● No accumulated water around installation

location.

●

Arrange filter at water inlet pipe, preventing

domestic water contaminated by impurities.

● Ensure water tank is full of water before

energizing.

3.4 Install Water Tank

1. Check water tank has complete accessories.

2. When mounted on ground, ensure the bottom of

water tank flat and vertically install water tank. If

mounted in bath room where water exists,

recommend installing on a foundation higher

than ground, preventing the bottom soaked by

water.

3. Temperature sensor should be inserted into

temperature probe as deeply as possible. Fix it

with provided cable fastening. (Cable tie must be

between temperature probe and cable fixed

head, seen below).

4. Because water pressure exists in water tank,

when magnesium rod is replaced, first close

water inlet valve and drain outlet for 10-20 sec,

and then replace magnesium rod. After

replacement, open water inlet valve. If water

sprays from water tank through above measures

taken, confirm water temperature in water tank,

preventing burns. Besides, do not place

electrical parts or electrical products near water

tank, preventing electrical shock or fire due to

electrical short-circuit.

3.5 Connect Water Module

Refer to the section 3.2 "Examples

of Application" in part II

Loading...

Loading...