19

English

Fe nce

A

Table o n Base

B

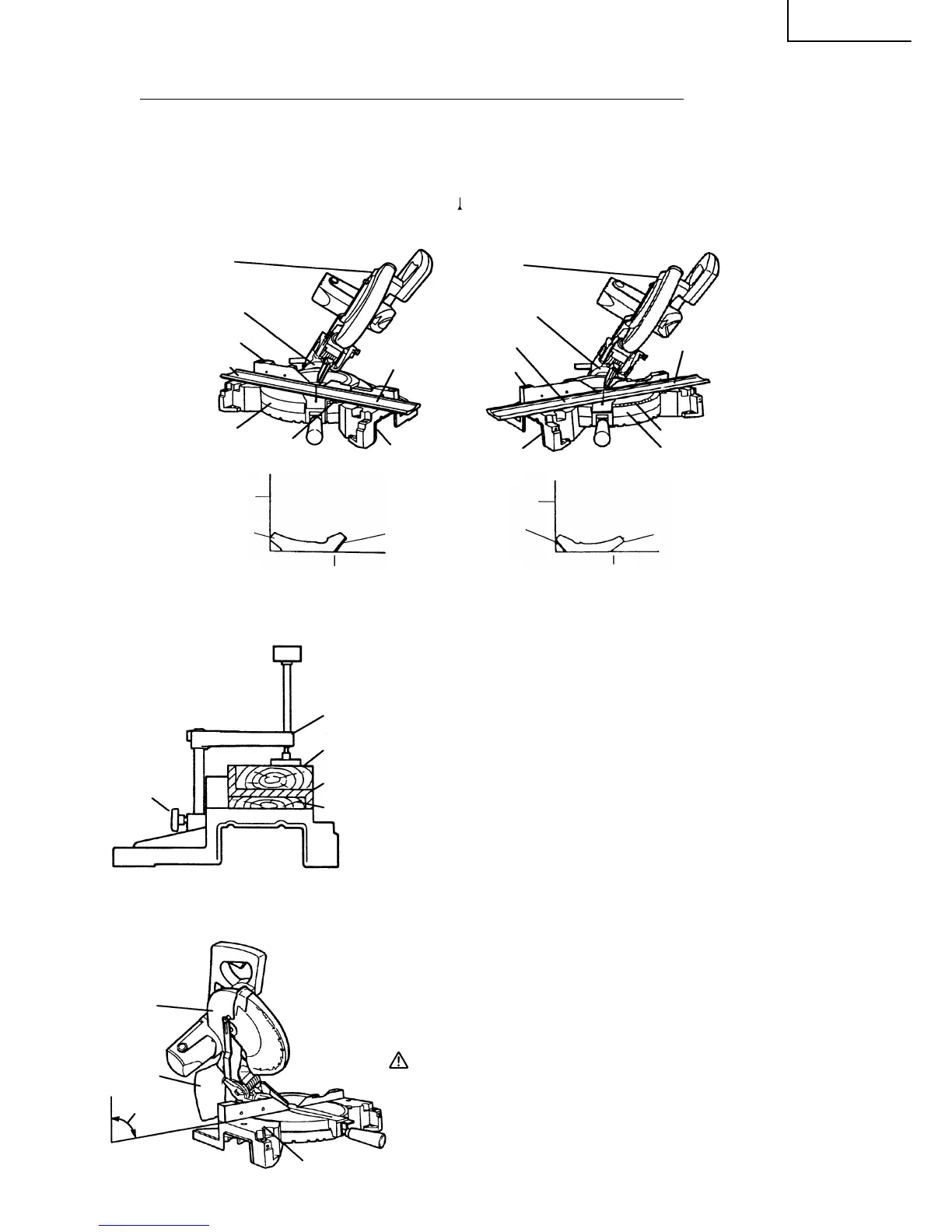

(4) Setting to cut cro wn m oldings at positions w and e in Fig. 25 (see Fig. 32):

q Turn the table to the left and set the Miter Angle as follo ws:

* For 45° type crow n moldings: 35. 3°

* For 38° type crow n moldings: 31. 6°

w Tilt the head to the right and set the Bevel A ngle as follows:

* For 45° type crow n moldings: 30°

* For 38° type crow n moldings: 33. 9° ( mark)

e Position the crown molding so that the lower surface (A in Fig. 24) contacts the fence as in Fig.

33.

Fig. 30 Fig. 32

Fig. 31 Fig. 33

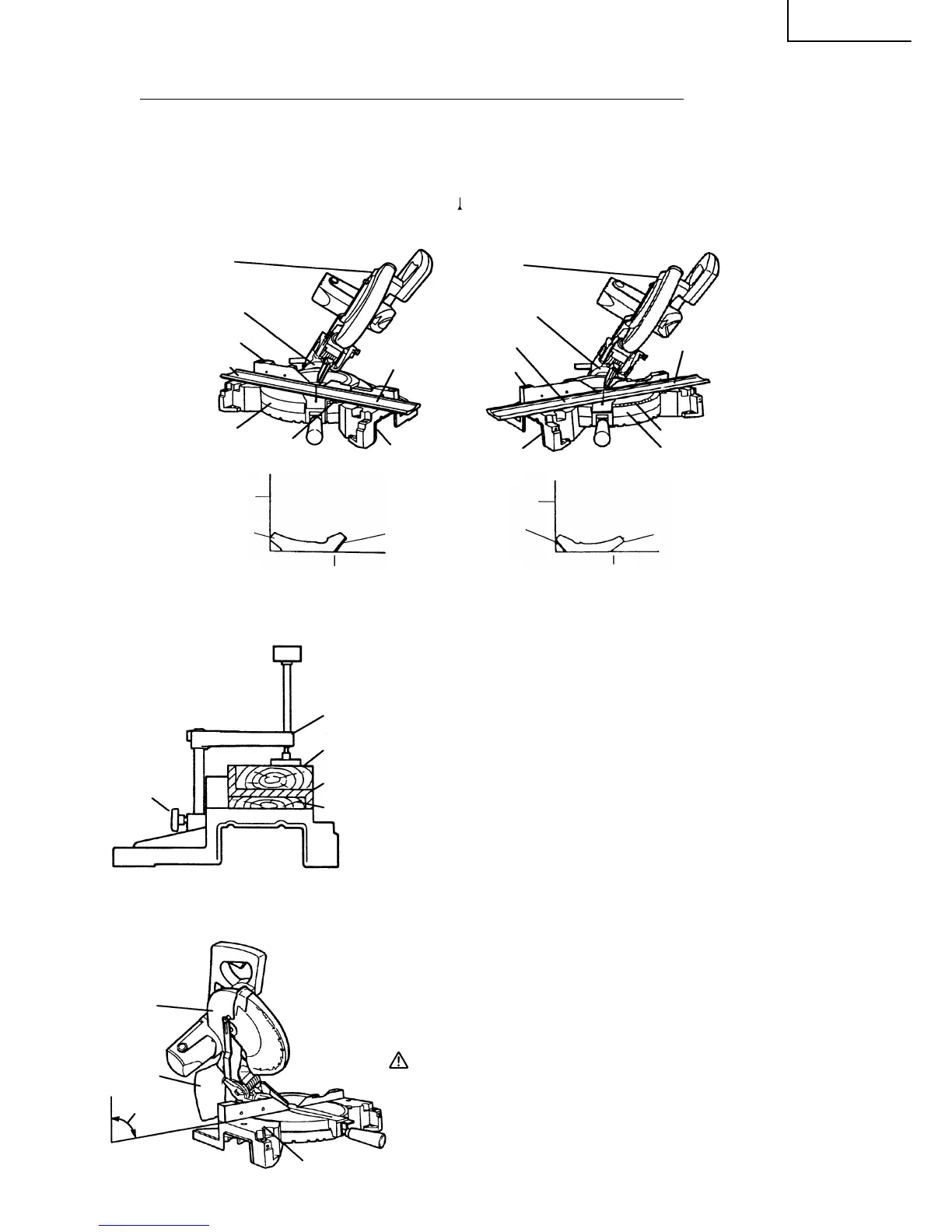

9. Cutting easily-deform ed materials, such as aluminum sash

M ateri als such as alu min u m sash ca n easil y defor m w h e n

tightened too m uch in a vise assembly. This will cause inefficient

cutting and possible overload of the m otor.

When cutting such materials, use a w ood plate to protect the

workpiece as shown in Fig. 34.

When cutting aluminum m aterials, coat the saw blade with cutting

oil (non-combustible) to achieve smooth cutting and a fine finish.

10. Ho w to use the dust bag (Standard accessory)

(1) W hen the dust bag has becom e full of sa wdust, dust will be

blow n out of the dust bag w hen the sa w blade rotates.

Check the dust bag periodically and e mpty it before it beco mes

full.

(2) During bevel and com pound cutting, attach the dust bag at a

right angle to the base surface as show n in Fig. 35.

CAUTION: Empty the dust bag frequently to prevent the

duct and the blade guard (metal) from becoming

clogg ed.

Sa wdust will accumulate more quickly than

normal during bevel cutting.

Fig. 34

q

Be vel A ngle

Scale

r

Fe nce

BaseMiter Angle Scale

Table

Head

Miter Angle Scale

Be vel A ngle

Scale

e

Base

Table

Head

Fe nce

w

Wood Plate

Vise

Assem bly

Wood Plate

5 m m

Cla mp Bolt

Alu minu m

Sash

Base S urface

Right

Angle

Bla de G uard

(M etal)

Dust Bag

Fe nce

B

Table on Base

A

Fig. 35

Loading...

Loading...