OM-944 Page 31

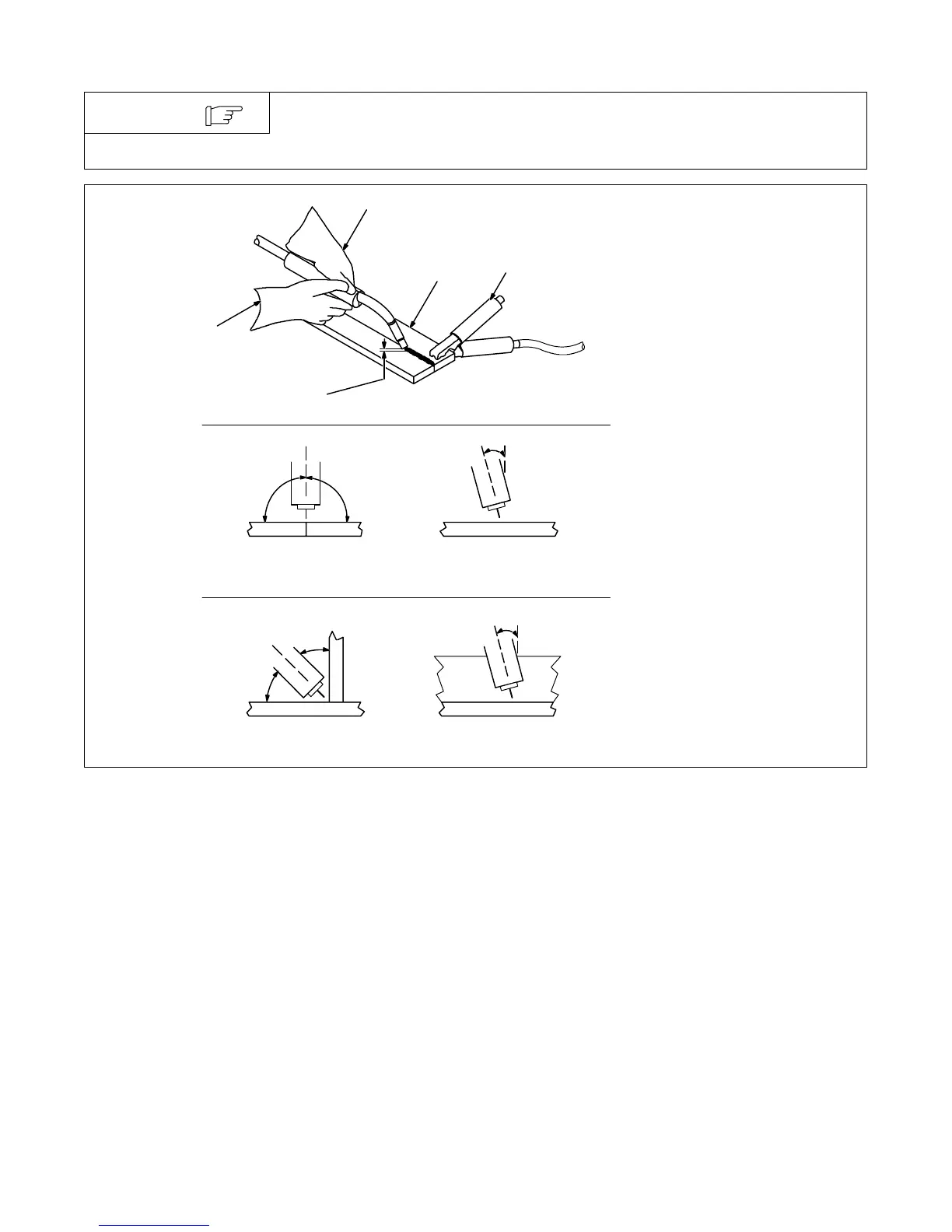

7-3. Holding And Positioning Welding Gun

Welding wire is energized when gun trigger is pressed. Before lowering helmet and

pressing trigger, be sure wire is no more than 1/2 in (13 mm) past end of nozzle,

and tip of wire is positioned correctly on seam.

NOTE

1 Hold Gun and Control Gun

Trigger

2 Workpiece

3 Work Clamp

4 Electrode Extension (Stickout)

1/4 to 1/2 in (6 To 13 mm)

5 Cradle Gun and Rest Hand on

Workpiece

2

3

5

4

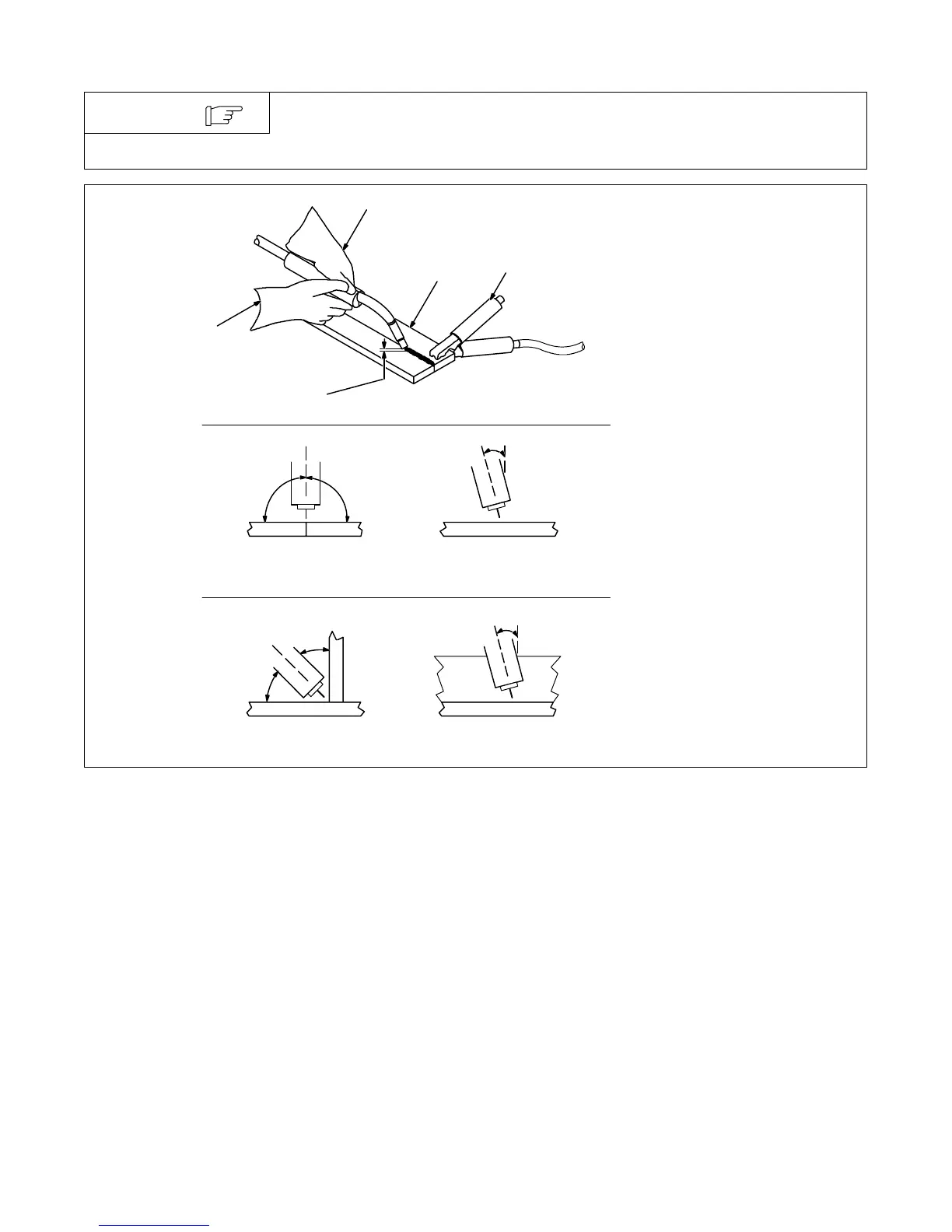

90° 90°

0°-15°

45°

45°

GROOVE WELDS

FILLET WELDS

End View Of Work Angle Side View Of Gun Angle

End View Of Work Angle Side View Of Gun Angle

1

0°-15°

S-0421-A

Loading...

Loading...