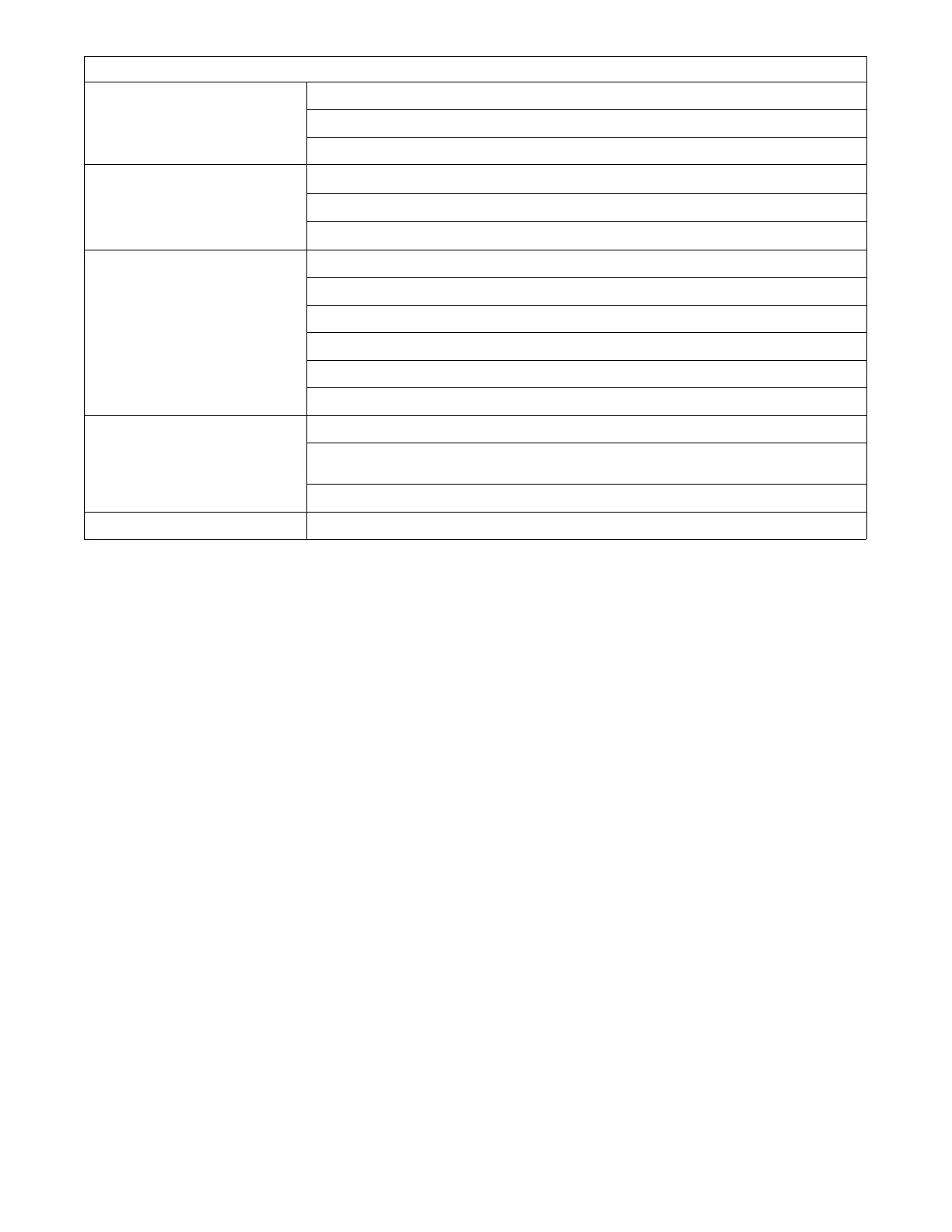

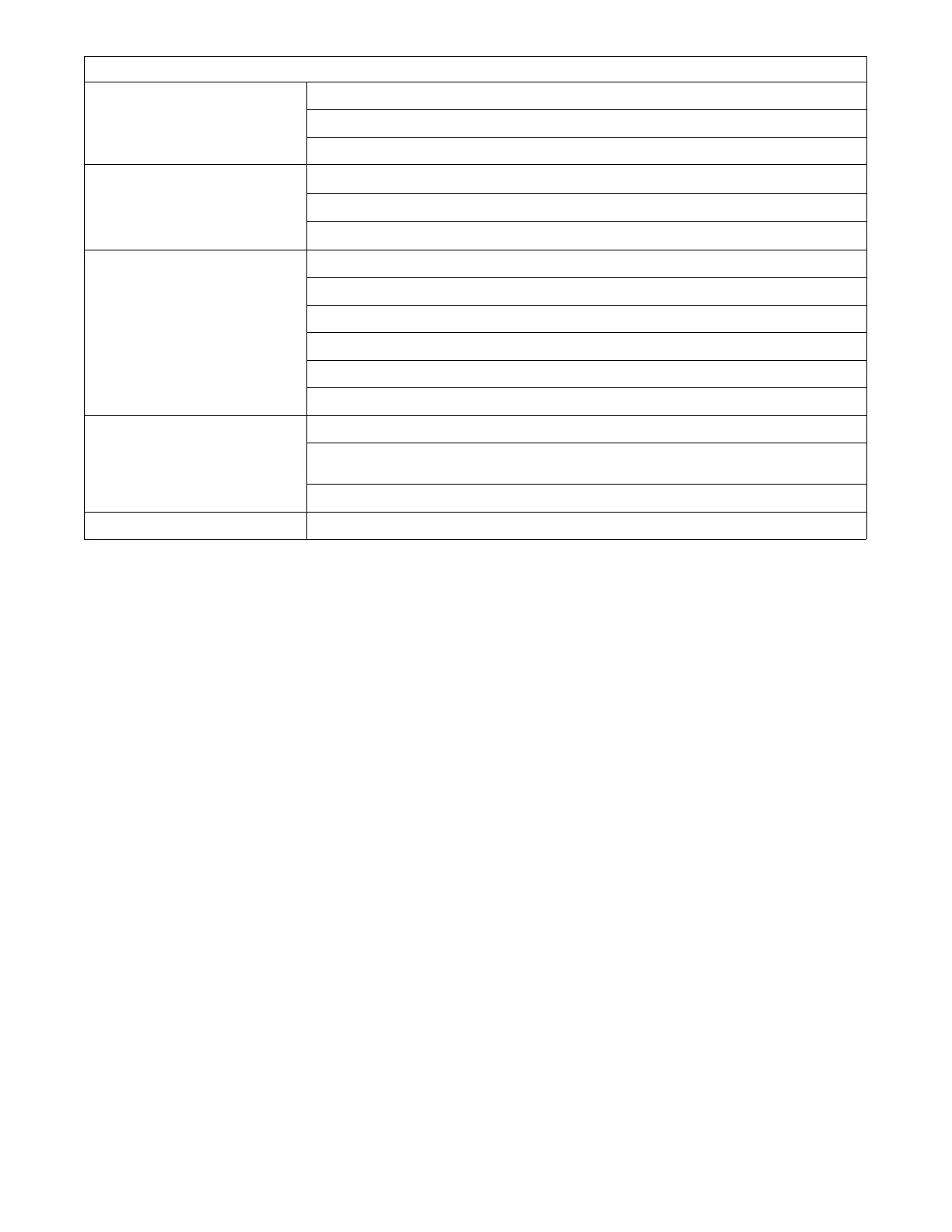

TM-258 267 Page 19Handler 140

Trouble Remedy

No weld output; wire feeds. Connect work clamp to get good metal-to-metal contact.

Replace gun contact tip (see Section 8-5).

Check thumbscrew securing gun end to feedhead adapter and tighten if necessary.

Low weld output.

Connect unit to proper input voltage or check for low line voltage.

Place Voltage switch S2 in desired position (see Section 5-1).

If using an extension cord, be sure that it is the proper size for the input voltage and amperage.

Low or erratic wire speed. Readjust weld parameter settings.

Change to correct size drive roll.

Readjust drive roll pressure.

Clean or replace wire inlet guide or liner if dirty or plugged (see Section 8-4 and/or 8-6).

Readjust wire reel hub tension.

Check voltage and connections of wire drive motor. Replace motor if necessary.

Improper or no shielding gas flow. Clean or replace gas hose.

Check shielding gas valve GS1 for proper coil voltage and connections. Check continuity of coil. Replace

GS1 if necessary.

Clear blockage in gun.

Shielding gas flows continuously. Replace contactor CR3.

Loading...

Loading...