22

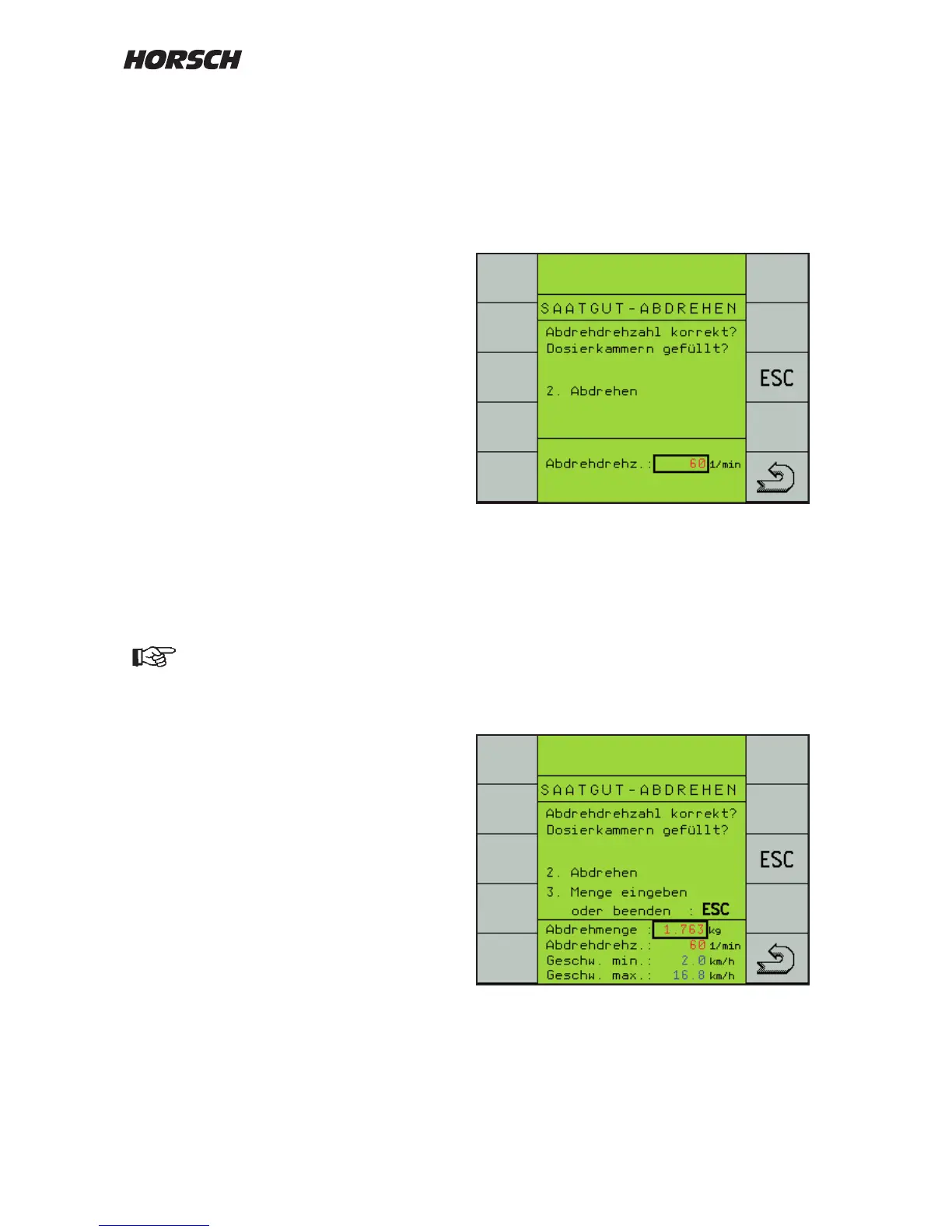

Starting calibration

Place a container or attach a calibration bag

under the metering unit, depending on the

machine.

Press the trac light button to start.

A second page "Calibration" appears.

With the "ESC"-key you can abort the process

at this point and start it anew.

The "Return"-key brings you back to the work

page.

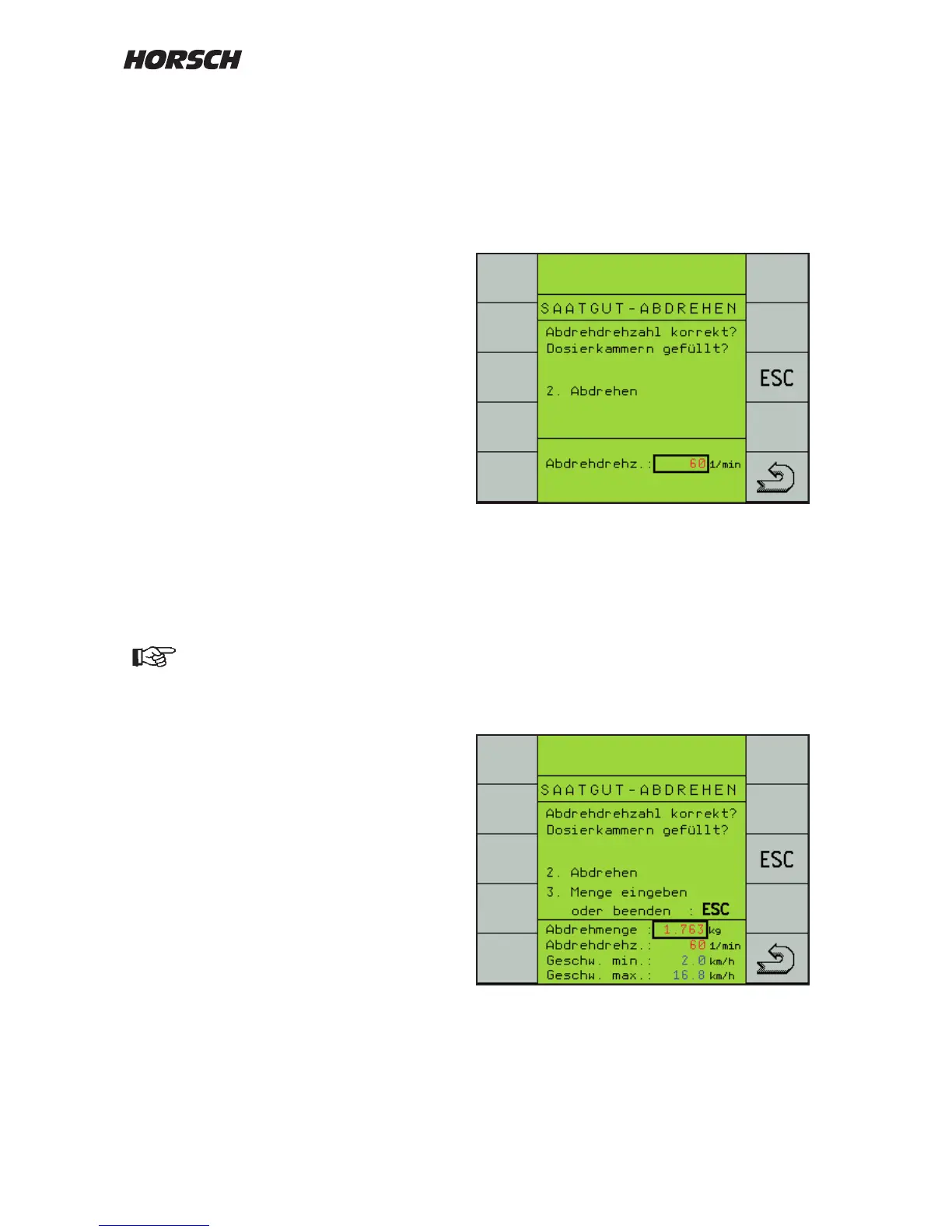

¾ Operate the calibration switch on the machine.

The rotor turns and fills the calibration

container.

¾ After switching o calibration the menu to

enter the calibration quantity appears.

Metering unit lled?

The hopper must be suciently lled with seed

before starting the calibration process. However,

the hopper should not be lled completely; this

applies particularly for ne seeding, to enable

easier exchange of rotor if it has been incorrectly

selected.

For correct calculation of the seed quantity all

cells in the rotor should be lled when starting

the seed calibration.

For this purpose press the key "Metering Unit".

The rotor will rotate as long as specied in the

"Conguration 3" menu under "prime rotor time",

or until the key is pressed again.

Calibration quantity

During the "Seed calibration" the computer

receives the calculation information required for

exact metering control.

It requires the seed weight taken from the

metering unit during seed calibration as input

value.

In order to keep measuring inaccuracies low, as

much seed as possible should be metered out.

Before the seed calibration you must

check and possibly clean the Venturi

area and the connected pipes from any

seed deposits. Residues falsify the

calibration quantity and thus the

complete drilling.

Loading...

Loading...