16

The general sequence

to

read

the

measured'magnitude

or

phase value

at

any

point

on

the

trace

is

as

follows:

CONVENIENT METHOD OF READING FREQUENCY USING THE

REFERENCE POSITION

LINE

OF UNUSED

CHANNEL

Model

8754A

DEVICE UNDER

~TEST

RESPONSE

,....

.fL

X

/t"'

...

I

n

I

I

--...

~

JV

vt"'

I

I

I

~

,r".

,r.'!

.r.1

.m

.rh.

},

.f.,

I

.m

.."

,

I

I

,

lY~

H

~

I

I

I

I

~1

MHz

I I .L

I

I

I

)V

~

.....

It-

O.6MHz

I

I

rv

,

]v

V

I

I

yV

Front

Panel

Introduction

REFERENCE POSITION

LINE OF UNUSED

CHANNEL

START

Proper selection

of

sweep time

is

essential for accurate measurements. This

is

accomplished

by

selecting

FAST, with

the

sweep time vernier fully clockwise,

then

decreasing

the

sweep time

by

rotating

the

vernier

counterclockwise and

if

necessary, selecting

the

slow sweep range until there

is

no change in

the

test device

response. The VIDEO

FILTER

reduces

the

post detection

bandwidth

and thus usually requires a

much

slower sweep.

As

you

increase

the

sweep width,

the

effective sweep rate increases, sometimes requiring a

slower sweep.

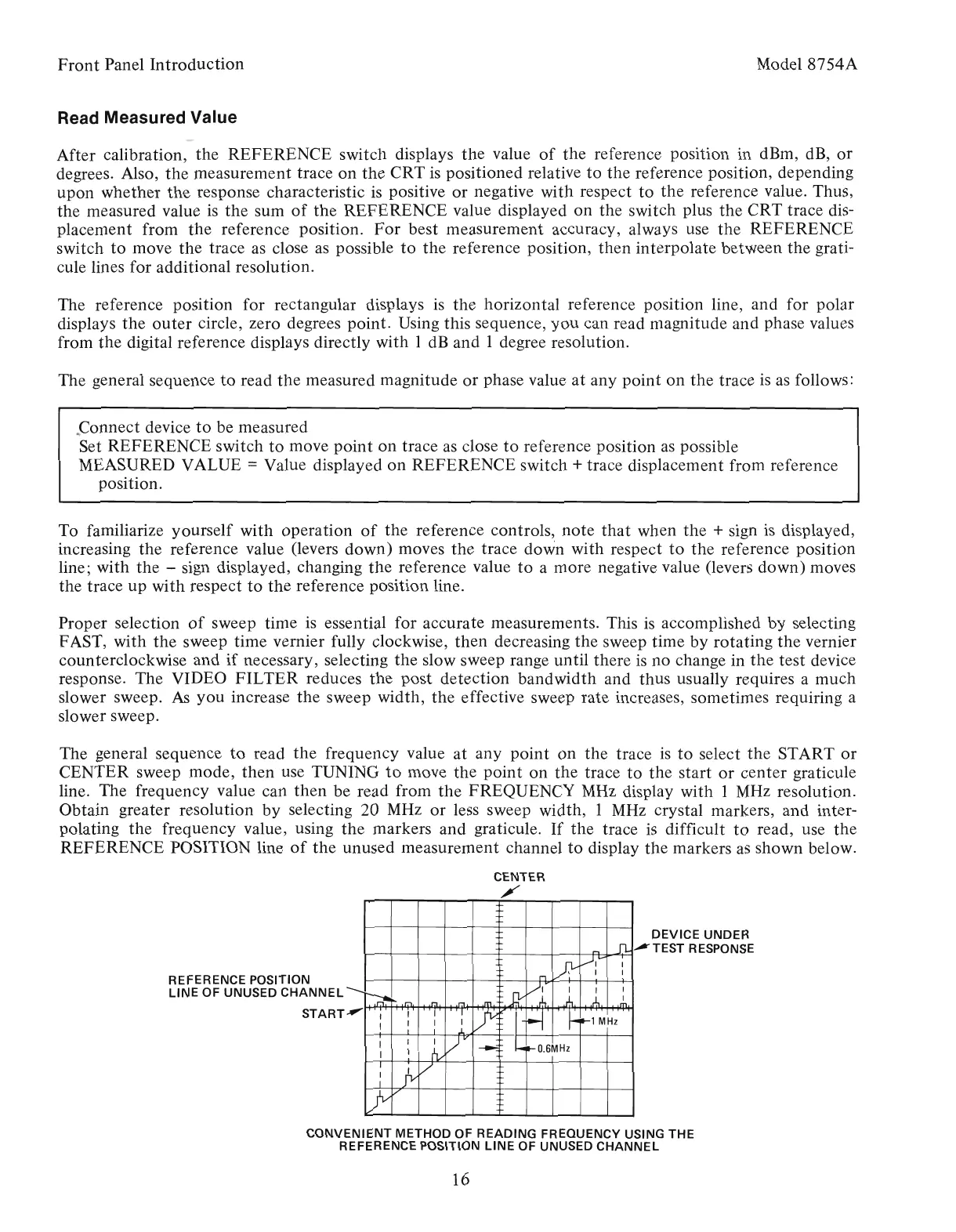

The general sequence

to

read

the

frequency value

at

any

point

on

the

trace

is

to

select

the

START

or

CENTER sweep mode,

then

use TUNING

to

move

the

point

on

the

trace

to

the

start

or

center

graticule

line. The frequency value can

then

be read from

the

FREQUENCY

MHz

display with I MHz resolution.

Obtain greater resolution

by

selecting 20 MHz

or

less sweep width, 1

MHz

crystal markers,

and

inter-

polating

the

frequency value, using

the

markers and graticule.

If

the

trace

is

difficult

to

read, use

the

REFERENCE POSITION line

of

the

unused measurement channel

to

display

the

markers

as

shown below.

CENTER

/'

Connect device

to

be measured

Set REFERENCE switch

to

move

point

on

trace

as

close

to

reference position

as

possible

MEASURED VALUE

= Value displayed

on

REFERENCE switch + trace displacement from reference

position.

To familiarize yourself with operation

of

the

reference controls,

note

that

when

the

+ sign

is

displayed,

increasing

the

reference value (levers down) moves

the

trace down with respect

to

the

reference position

line; with

the

- sign displayed, changing

the

reference value

to

a more negative value (levers down) moves

the trace

up

with respect

to

the

reference position line.

The reference position for rectangular displays

is

the

horizontal reference position line, and for polar

displays

the

outer

circle, zero degrees point. Using this sequence,

you

can read magnitude and phase values

from

the

digital reference displays directly with I dB

and

I degree resolution.

Read Measured Value

After calibration,

the

REFERENCE switch displays

the

value

of

the

reference position in dBm, dB,

or

degrees. Also,

the

measurement trace

on

the

CRT

is

positioned relative

to

the

reference position, depending

upon

whether

the response characteristic

is

positive

or

negative with respect

to

the

reference value. Thus,

the measured value

is

the

sum

of

the

REFERENCE value displayed

on

the

switch plus

the

CRT trace dis-

placement from

the

reference position.

For

best measurement accuracy, always use

the

REFERENCE

switch

to

move

the

trace as close as possible

to

the

reference position,

then

interpolate between

the

grati-

cule lines for additional resolution.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...