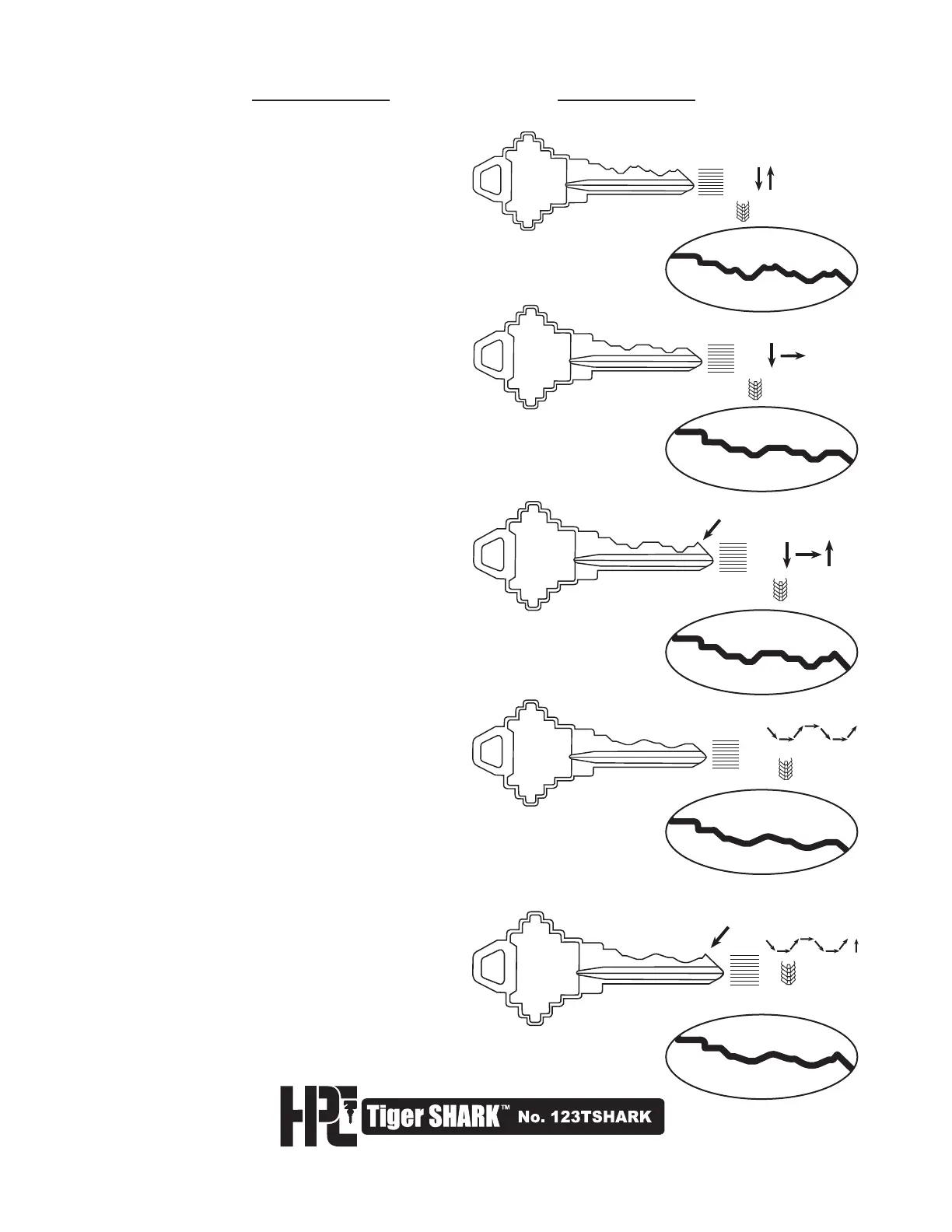

5.2.1 Cut Styles

4 7 2 5 9 5

1

2

3

4

5

6

7

8

9

CUTTER

MOTION

BARB

4 7 2 5 9 5

1

2

3

4

5

6

7

8

9

CUTTER

MOTION

4 7 2 5 9 5

1

2

3

4

5

6

7

8

9

CUTTER

MOTION

1. The Plunge Cut (PLUNGE) is the standard cut style.

It is made when the cutter comes straight down into

the blank, backs off, and moves in again to make the

next cut after the carriage has moved to the next cut

position.

2. A Contour Cut (CONT) eliminates peaks between

cuts. It is created when the cutter moves forward to

make the first cut, and then moves straight laterally to

the next position before moving in to cut the next

depth in the sequence.

3. A Contour with Barb Cut (CONT-B) eliminates peaks

but leaves the end of the key uncut for key retention.

It is made when the cutter moves forward to make the

first cut, and then moves straight laterally to the next

position,and upon the last cut, moves outward to create

the characteristic barb on the key blade end.

CUTTER

MOTION

4 7 2 5 9 5

1

2

3

4

5

6

7

8

9

CUTTER

MOTION

4 7 2 5 9 5

1

2

3

4

5

6

7

8

9

BARB

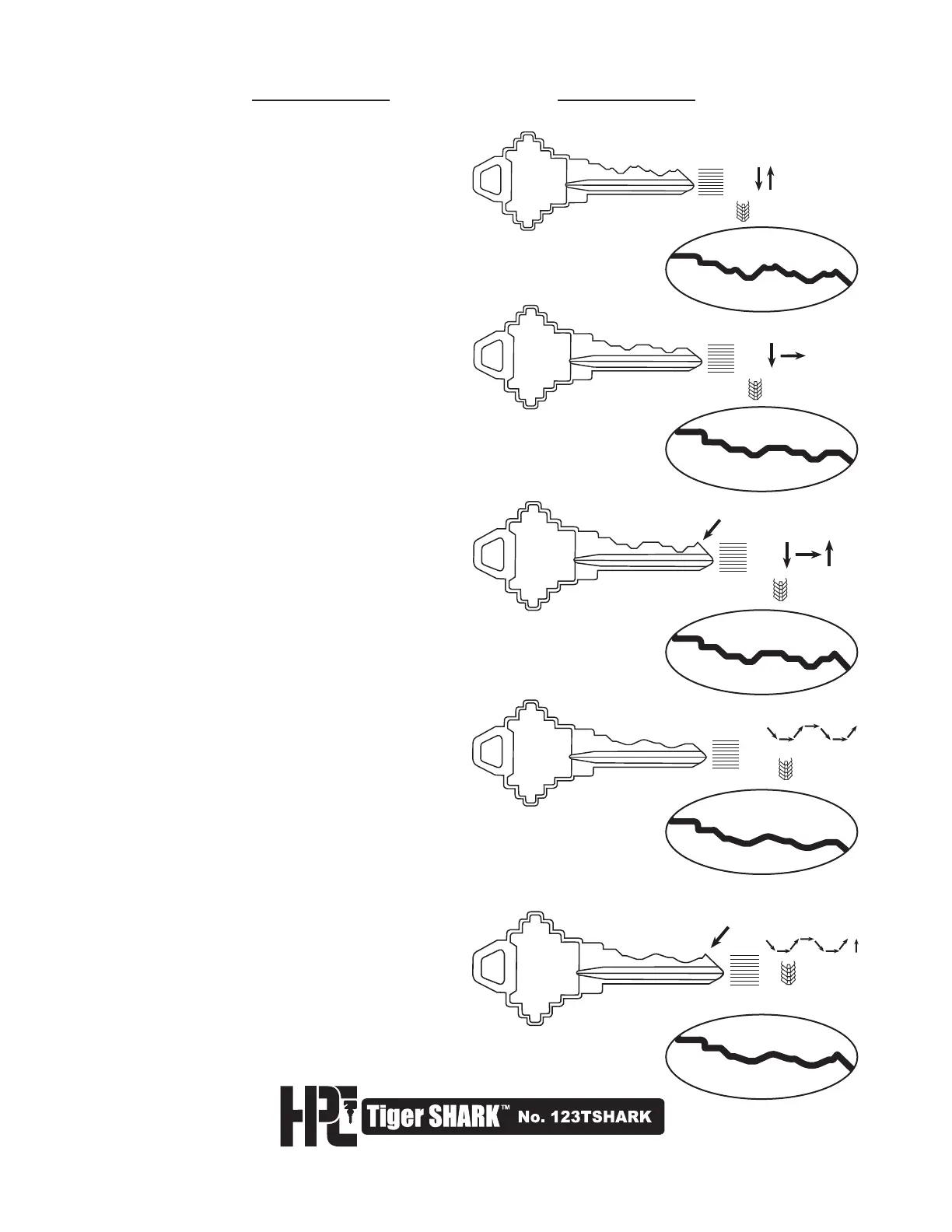

4. A Smooth Cut (SMOOTH) is made by the cutter wheel

moving from depth to depth across the key blade at an

angle instead of straight. It determines the best angle

between cuts with no peaks.

5. A Smooth with Barb Cut (SMTH-B) is made like the

Smooth Cut, with the cutter following at an angle, and

then withdrawing after the last cut to form the

characteristic barb. It determines the best angle but

leaves the end of the key uncut for key retention.

Loading...

Loading...