6 Operation and regulation

74

HSD S.p.A. © - 0106h03a.fm100713

6.7 Procedure to follow if the tool becomes jammed

in the piece being machined

If possible, free the piece by hand and then perform a tool change.

If this is not possible, proceed as follows:

Supply air to the tool change circuit

Slowly move the spindle away from the workpiece by moving it along the Z-axis until the collet

opens (sensor S2 output “ON”)

Make sure that the cone has been freed from the collet

Move the spindle away from the workpiece

Then manually remove the jammed tool.

If this procedure is not followed, the tool holder will drag the locking system (collet/screw dowel)

with it until the cone is released. After which, the collet will move back violently due to the force

exerted by the spring and could cause damage to the screw dowel.

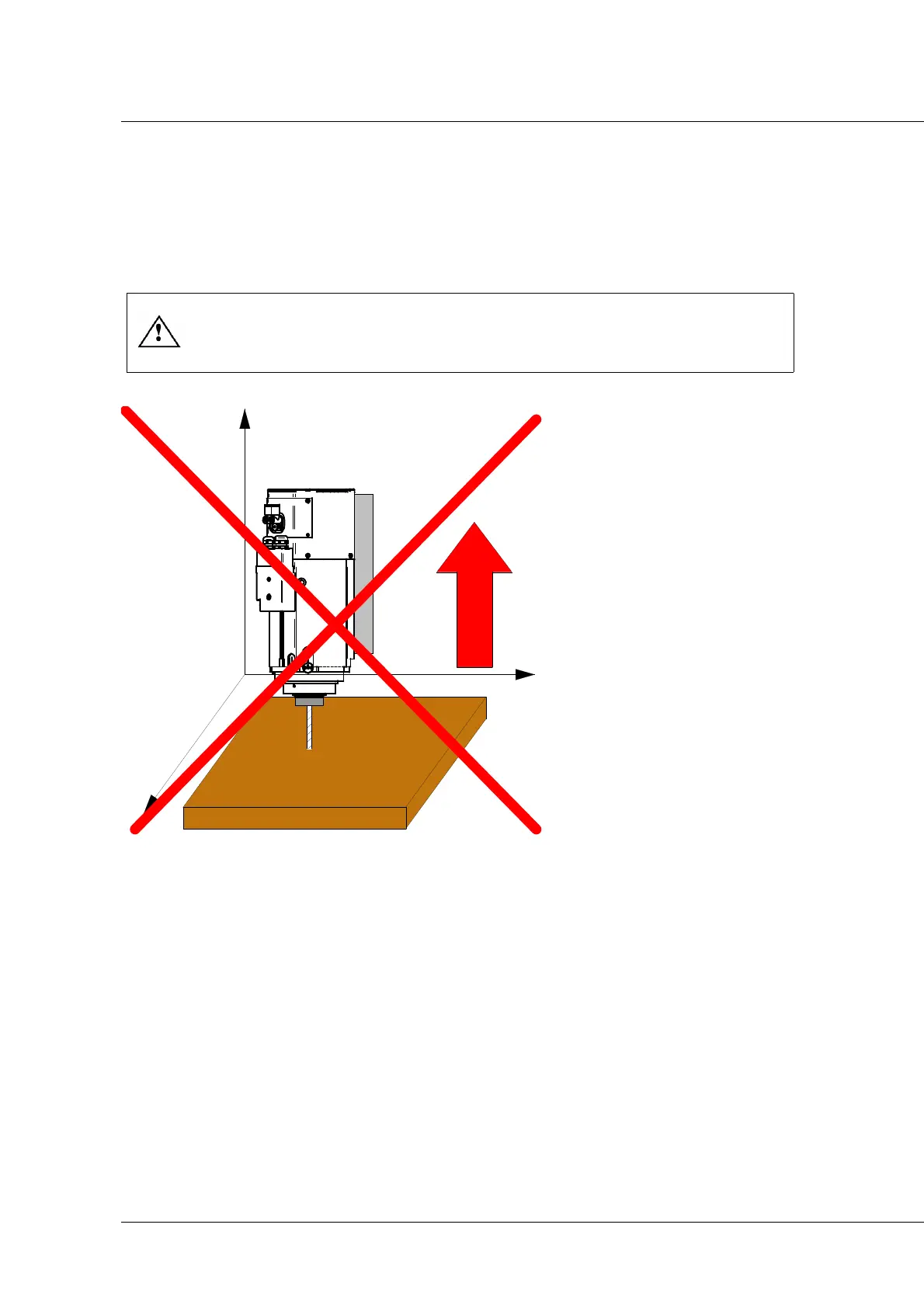

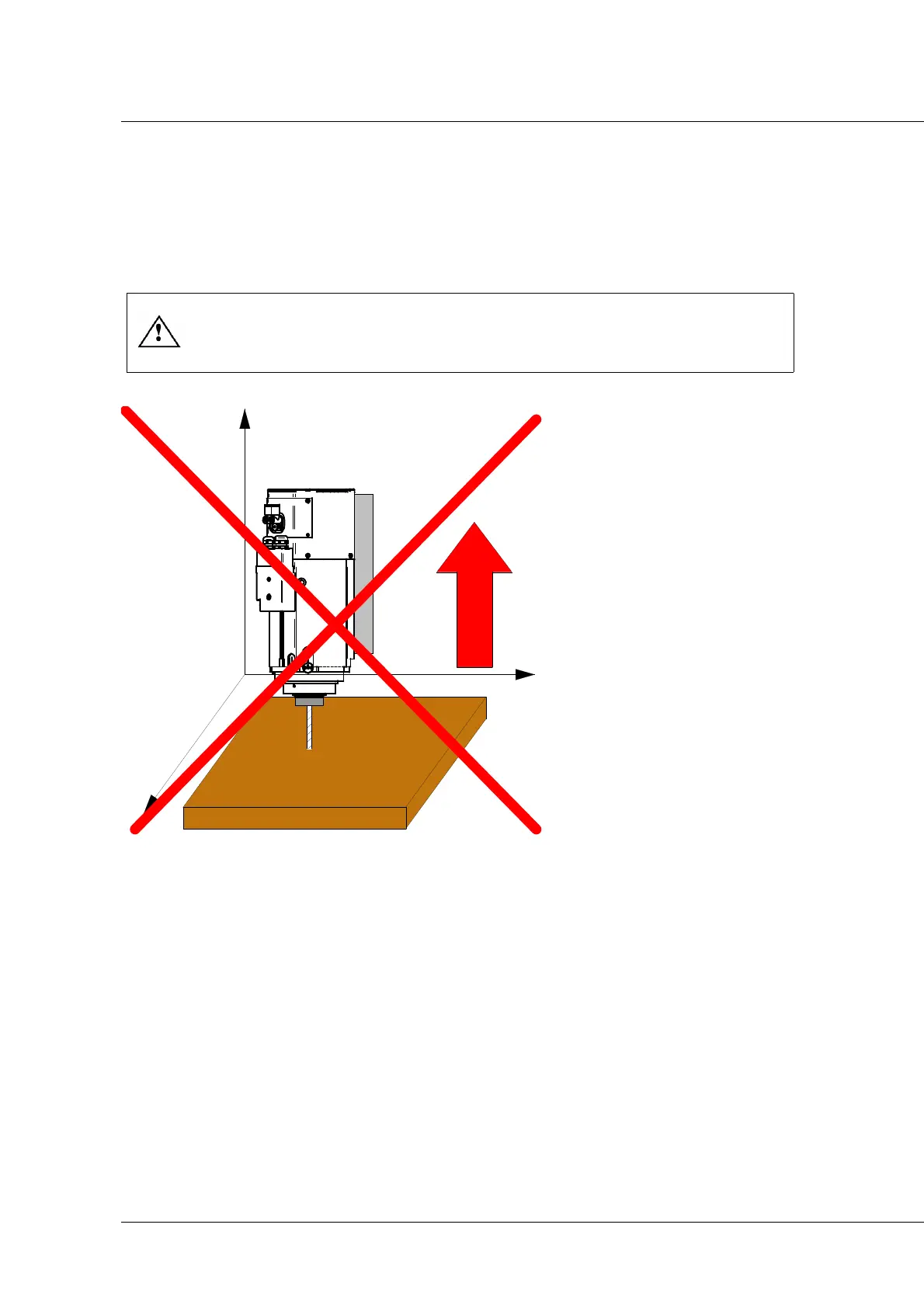

For models with ISOP type tool coupling, in the case where the machine goes

into alarm status or stops with the tool locked onto the piece being machined,

do not move the spindle along the Z-axis!

Loading...

Loading...