7 Programmed maintenance

92

HSD S.p.A. © - 0107h00a.fm100713

7.1 Daily maintenance

7.1.1 Control and cleaning of the tool holder seat and tool

holder cone

The surfaces of contact

between tool holder and tool

holder seat must be kept

clean to ensure a secure

coupling.

At the beginning of the

working day, make sure that

the surfaces highlighted in the

figures from 7to 10are clean,

and free of dust, grease,

coolant, oil, metal particles or

machining waste, as well as

free of traces of oxide or

scale;

if necessary, clean with a

clean and soft cloth.

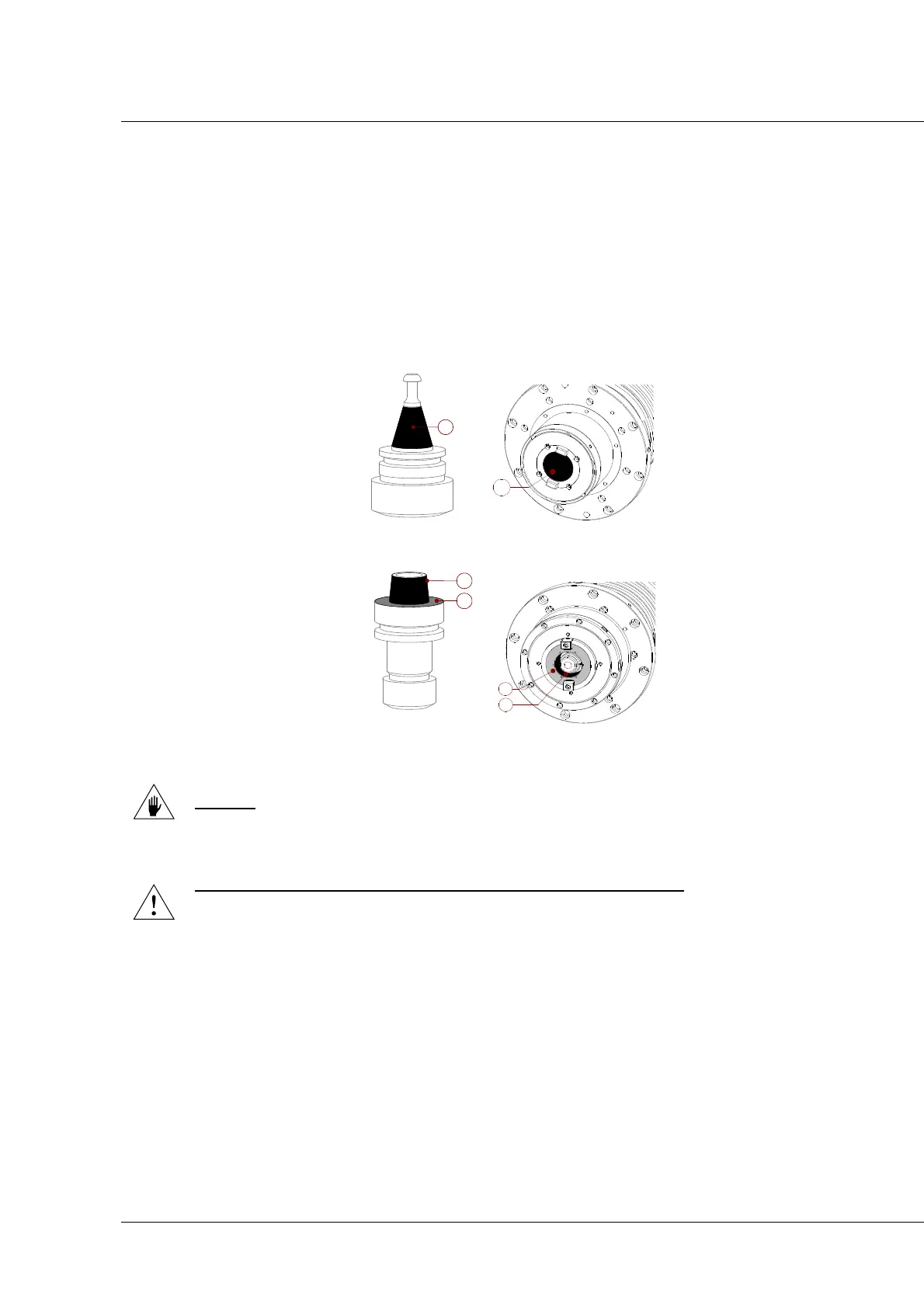

Figure 7:

ISO tool holder

Figure 8:

ISO tool holder seat

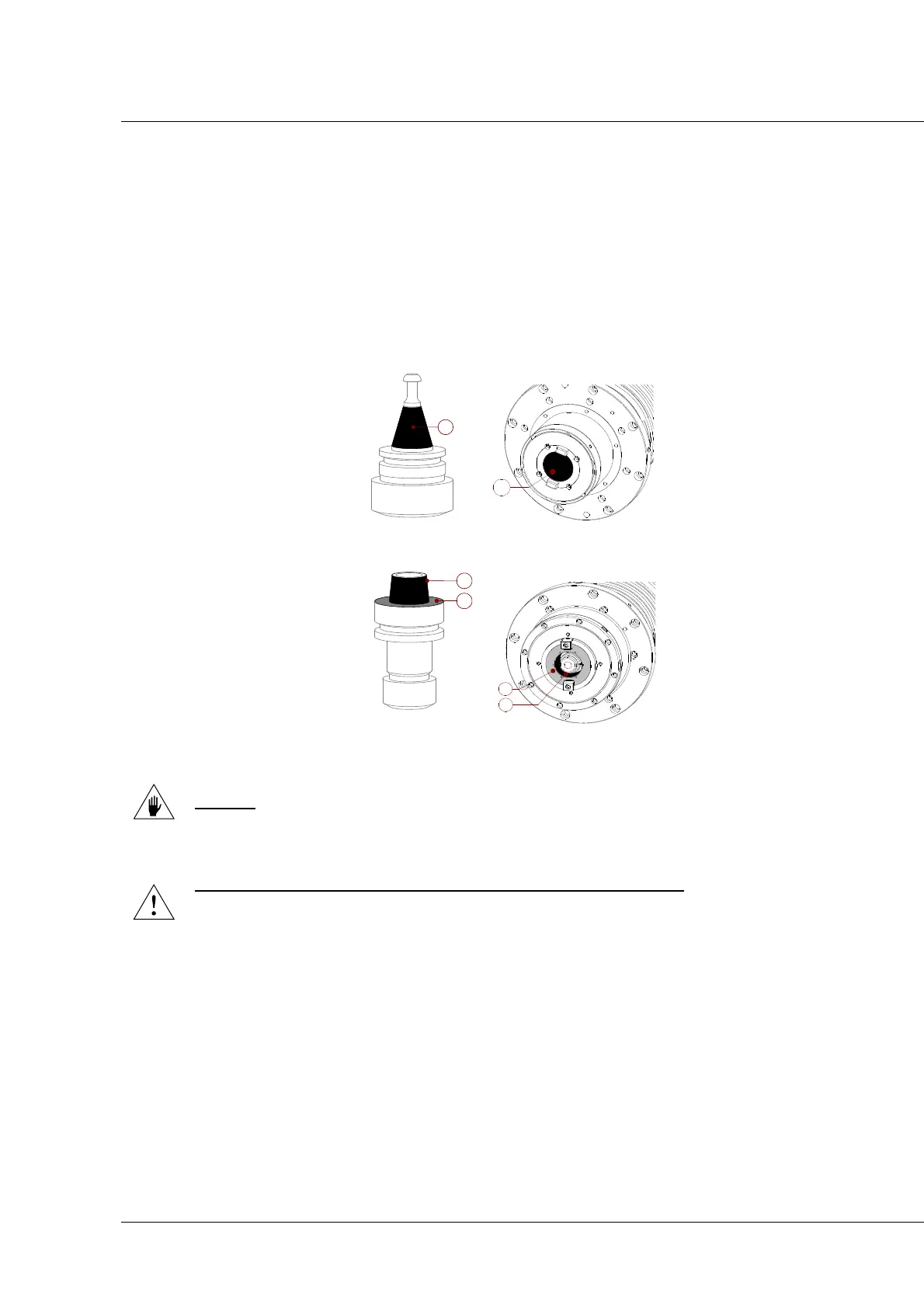

(1) Conical

surfaces

(in black)

(2)

Contact

surfaces

(in grey, HSK

only)

Figure 9:

HSK tool holder

Figure 10:

HSK tool holder seat

To clean the highlighted surfaces, use a soft clean cloth;

DO NOT

use abrasive tools such as steel wool, metal brushes, emery cloth,

acids or any other aggressive means.

At the end of the working day clean the surfaces highlighted in figures

from 7 to 10 with a soft and clean cloth; imperfect cleaning can lead to serious

consequences for the user's safety, the wear of the electrospindle and the tool

holder, and the accuracy and efficiency of the machining operation.

Loading...

Loading...