Installation and Maintenance Manual

10

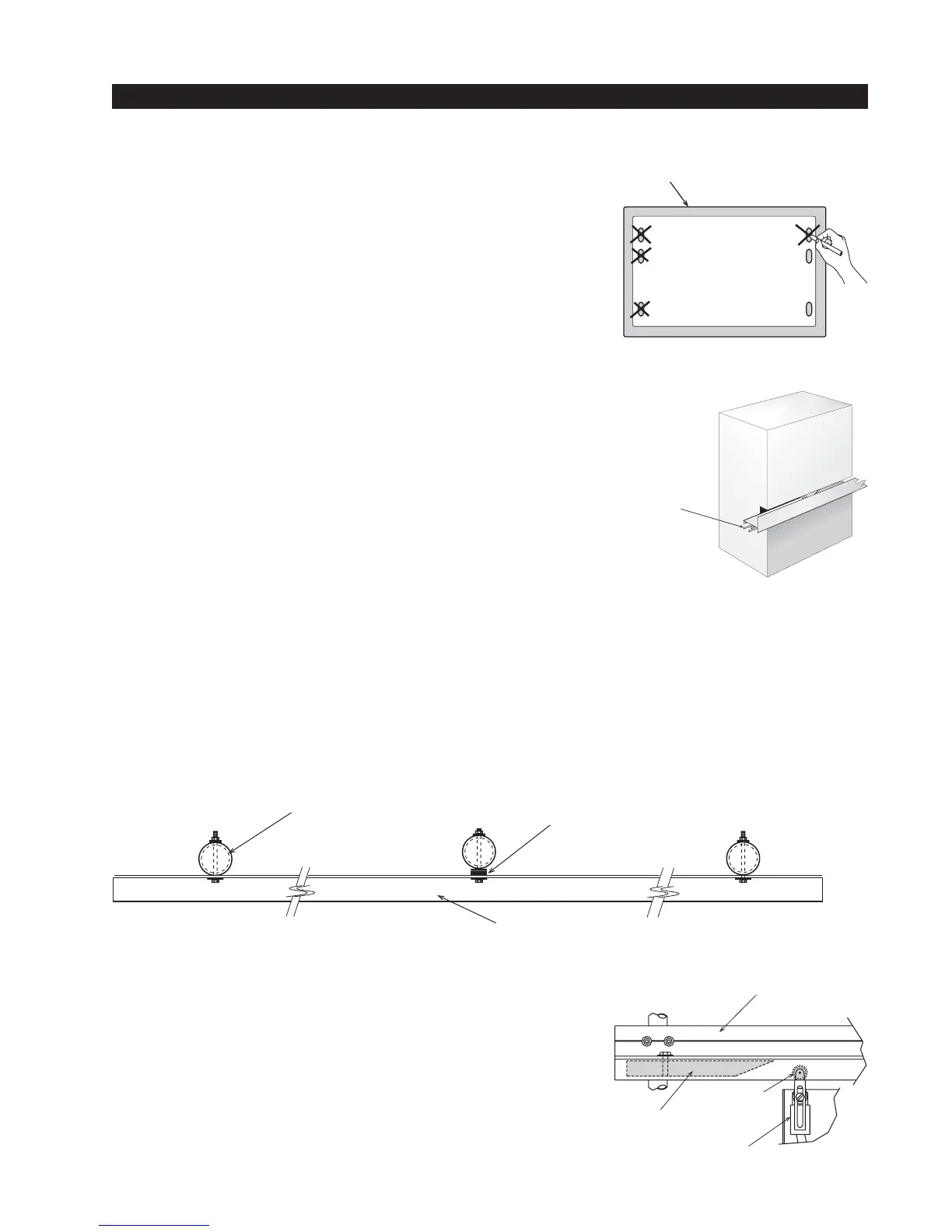

slab

Roll pins line

up drive rail

segments to

assure perfect

splicing

fencepost shim as necessary

drive rail

drive rail

limit ramp

limit roller

limit switch

Installation

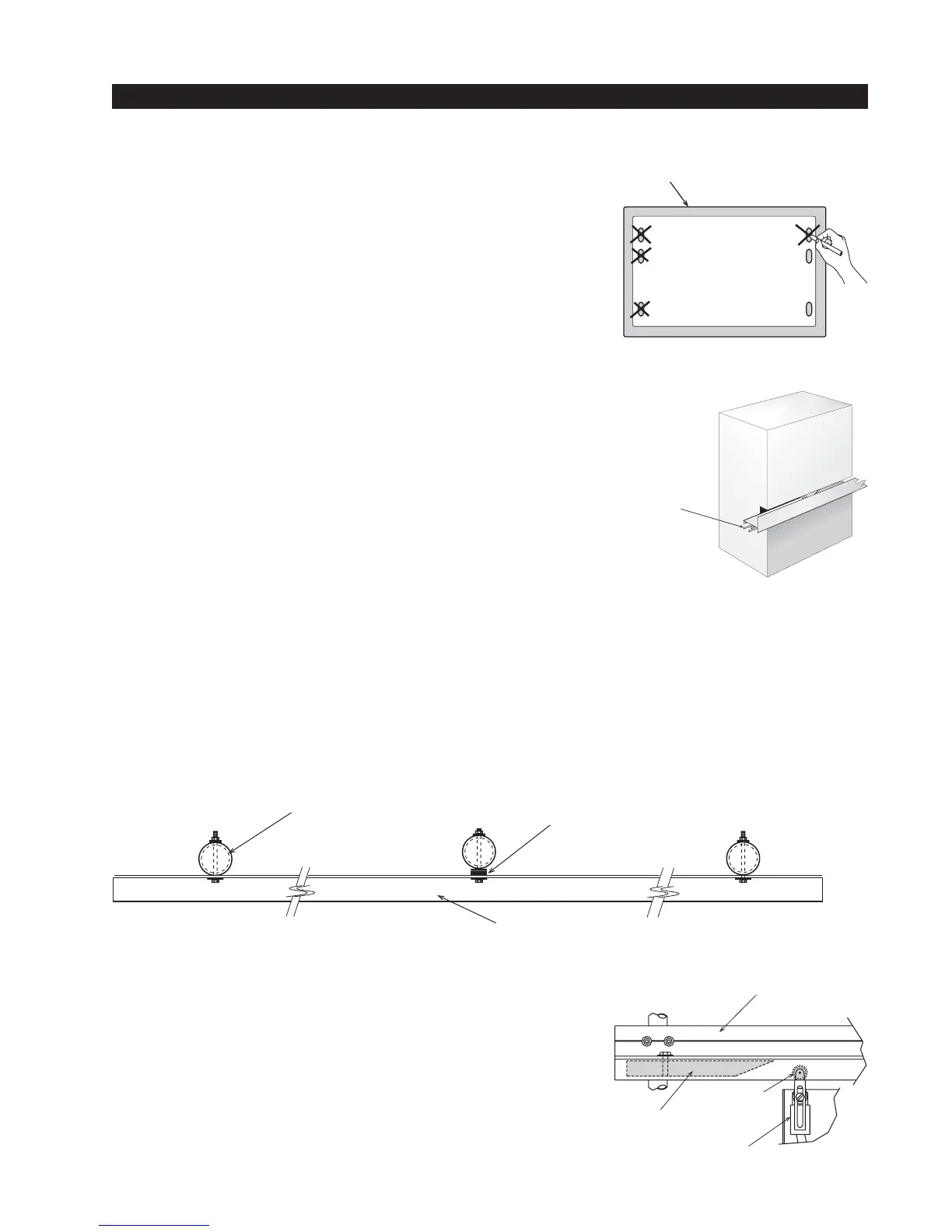

1. Drill four holes for concrete anchors

Each operator comes with a paper template with the anchor

slots. Place the template on the slab; making sure that it is

parallel to and 1 3/4" from the gate. Trace the slots, remove the

template, and then scribe the locations for your anchor bolts.

Drill holes for the anchor bolts in the center of the slots you

marked, so that you will have some room for adjustment. There

are six mounting slots in the chassis, install at least four 1/2 “ x

4” concrete anchor bolts, using two per side.

2. Line up the operator

Put the operator in position onto the anchor bolts. Verify that the

operator is parallel and 1 3/4" away from the gate on both the left

and right sides, and then tighten the anchors securely.

3. Two part Operators (battery models and 333 modular

models)

These two part operators come with a separate enclosure, which

should be mounted within 10 feet of the operator, but not more

than 100 feet. We recommend wall mounting or using two 4"

posts, with horizontal mounting strut to create a support for this

enclosure.

4. Bolt the Drive Rail to the Gate Panel

Connect multiple sections of drive rail together with 1/4" roll pins for a perfect splice. The drive rail

must be bolted to each vertical member of the gate panel. This may be done with U-bolt clamps or

through bolts, however U-bolt clamps allow for easy up down adjustment. If the gate is bent or

warped, shim the drive rail so that it is straight ± 1/4" throughout the travel of the gate. When the

drive rail has been installed at the correct height, the top surface is 9 3/4" above the operator base.

A label on each side of the operator indicates the correct height.

5. Install Limit Ramps on Underside of Drive Rail

Push the gate to the fully closed position and drill a 3/8" hole in

through the drive rail to mount a 12" plastic limit ramp under the

drive rail, in the wheel channel, at a location that will trip the

limit switch approx. 6" before the exact spot you want the gate

to stop. Adjust the lever arms on the limit switch so that the

roller clears the underside of the drive rail by at least 1/4 inch.

Push the gate fully open and repeat this procedure with the

other limit ramp. See the Drive Rail drawing S22 on page 16.

Loading...

Loading...