10--6

121

Use and maintenance manual S20DSP

SOLUTIONPROBABLE CAUSEPROBLEM

Blade path fault

' Front flywheel position incor-

rect

.Check that the band saw is

correctly positioned on the

flywheel. Adjust the position

of the flywheel under the

blade, moving the shaft of

the flywheel

' Flywheels worn .Replace

' Gaps full of swarf .Clean inside machine using

blown air.

' Blade guide head alignment .Check and adjust

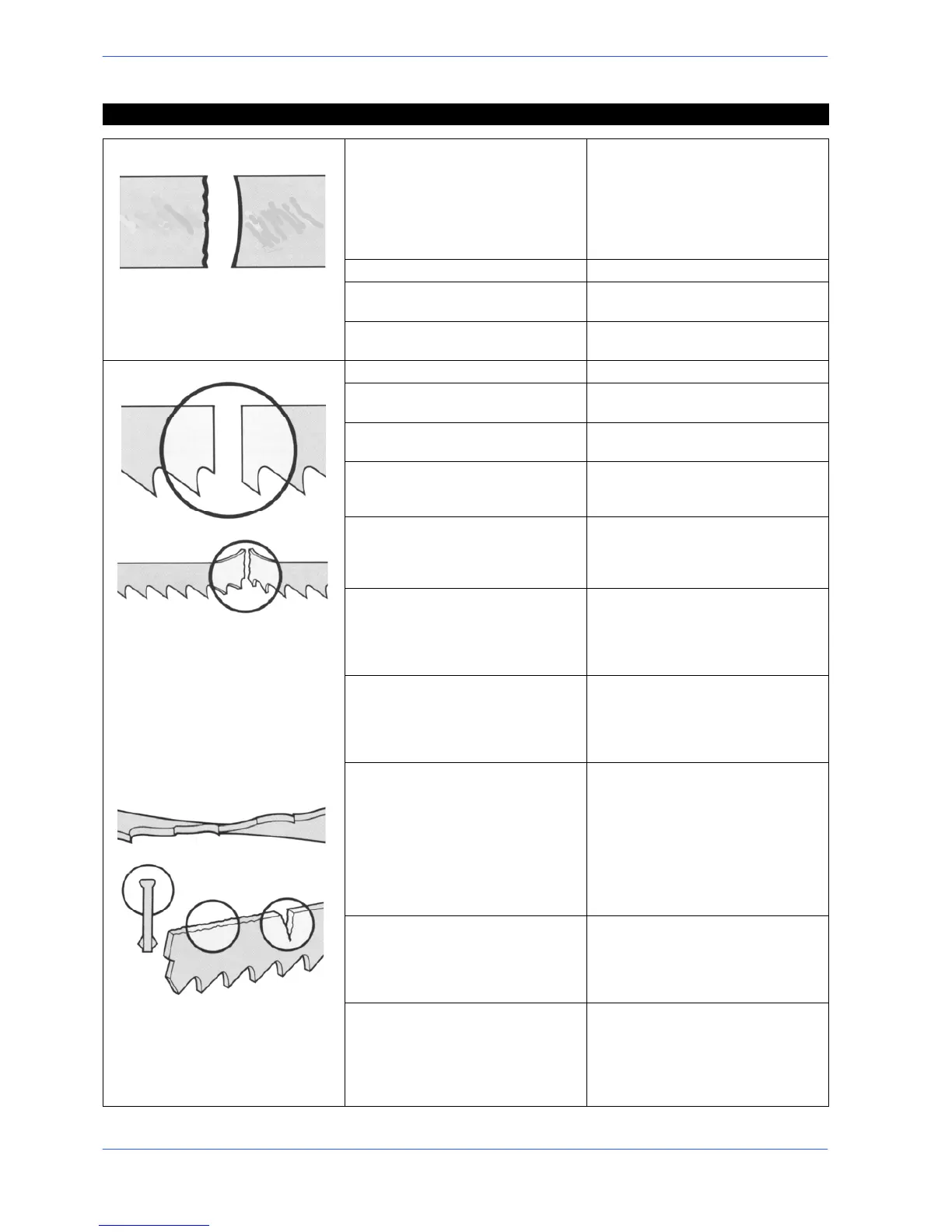

Blade broken

' Cutting speed too high .Reduce cutting speed

' Head downstroke too fast .Reduce head downstroke

speed

' Cutting pressure too high .Check and set to correct

pressure

' Tooth pitch unsuitable .Teeth too close together:

change the blade for one

with coarser tooth spacings

' Workpiece not clamped

properly

.The blade may break if the

workpiece moves during cut-

ting: check the vice, jaws and

clamping pressure.

' Widia inserts positioned in-

correctly

.Adjust inserts position, es-

pecially the width, since

blade thickness can exceed

the manufacturer’s declared

tolerance ratings

' Widia blade steady buttons .Can have a milling action on

the back of the blade if worn

or chipped, causing cracks

from the back towards the

teeth.

' Position of blade on fly-

wheels incorrect

.The blade may be scraping

on the edges of the fly-

wheels: this problem is gen-

erally caused by blades

which are deformed or

wrongly welded (conical) Ad-

just the position of the front

flywheel by moving the pin,

or change the blade

' Blade tension incorrect .If the blade tension is too

high or too low, the blade will

be subjected to abnormal

stress: set the tension back

to the rated value.

' Blade weld fault .The point at which a blade is

welded is its most critical

point; problems could be

caused by welds which are

not aligned perfectly or have

inclusions or blowholes

Loading...

Loading...