5--3

31

Description of machine operation

Hydraulic adjuster for choosing the head

lowering speed

THERMAL- MAGNETIC CIRCUIT- BREAKER WITH UNDERVOLTAGE

COIL AND DOOR LOCKING DEVICE

On the left side of the control board, the machine i s equipped with a main switch

that, when set ON (1), powers the machine. When set to ON (1), this switch

powers up the machine. The main switch is fitted with three power failure

protection systems. In fact, in the event of a power failure, this switch disconnects

all the electrical devices, causing the machine to immediately shut down, and

prevents it from automatically starting up again when power is restored. This

device also resets the thermal relay fitted to protect against current overloads.

Basic instructions for carrying out a cutting operation cycle

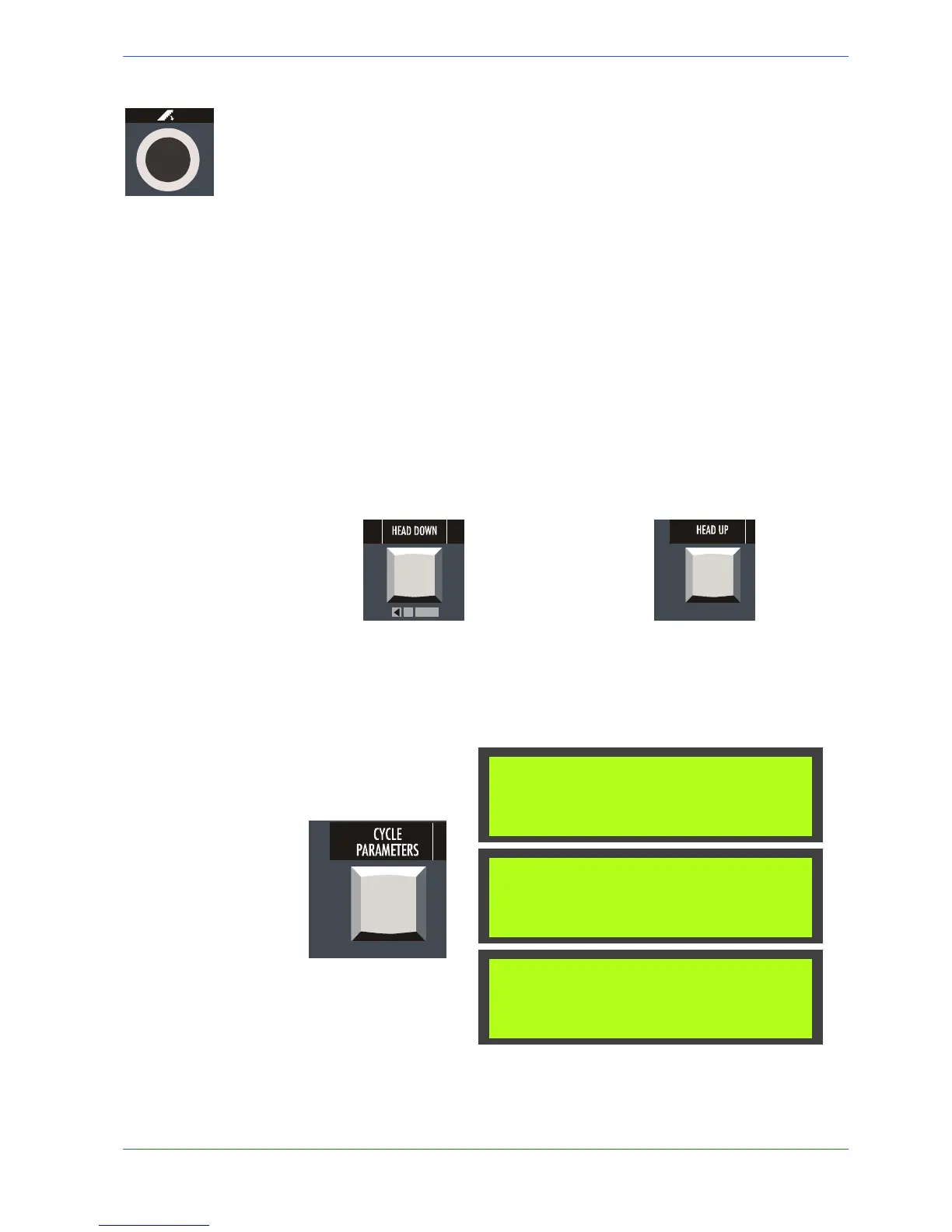

Manoeuvring the cutting head

The cutting head may be operated by the head “up” and “down” buttons of the

Head Positioning System (previously illustrated in the key for the control console

keyboard), which are enabled in SEMI---AUTOMATIC mode.

Head “down” key Head “up” key

During any processing cycle it is possible to control the machine operating

parameters TL (blade tensioning) and PT (head position), pressing the key

below it is also possible to display the values VL (blade speed), T (cutting

time), PZ (cut piece counting) and I (motor current absorption).

SEMIAUT.:PRONTO

TL=0880 PT=0968

SEMIAUT.:PRONTO

VL=0 T=00:00:00

SEMIAUT.:PRONTO

PZ=0001 I=00.0A

Clamping the work piece in the vice

Vice opening and closure is controlled by the corresponding buttons on the

control console. However, to ensure that the workpiece is securely clamped in the

vice, proceed as follows:

N.B.

Loading...

Loading...