Powermax30 AIR Operator Manual 808840 55

5 – Maintenance and Troubleshooting

Inspect the consumables

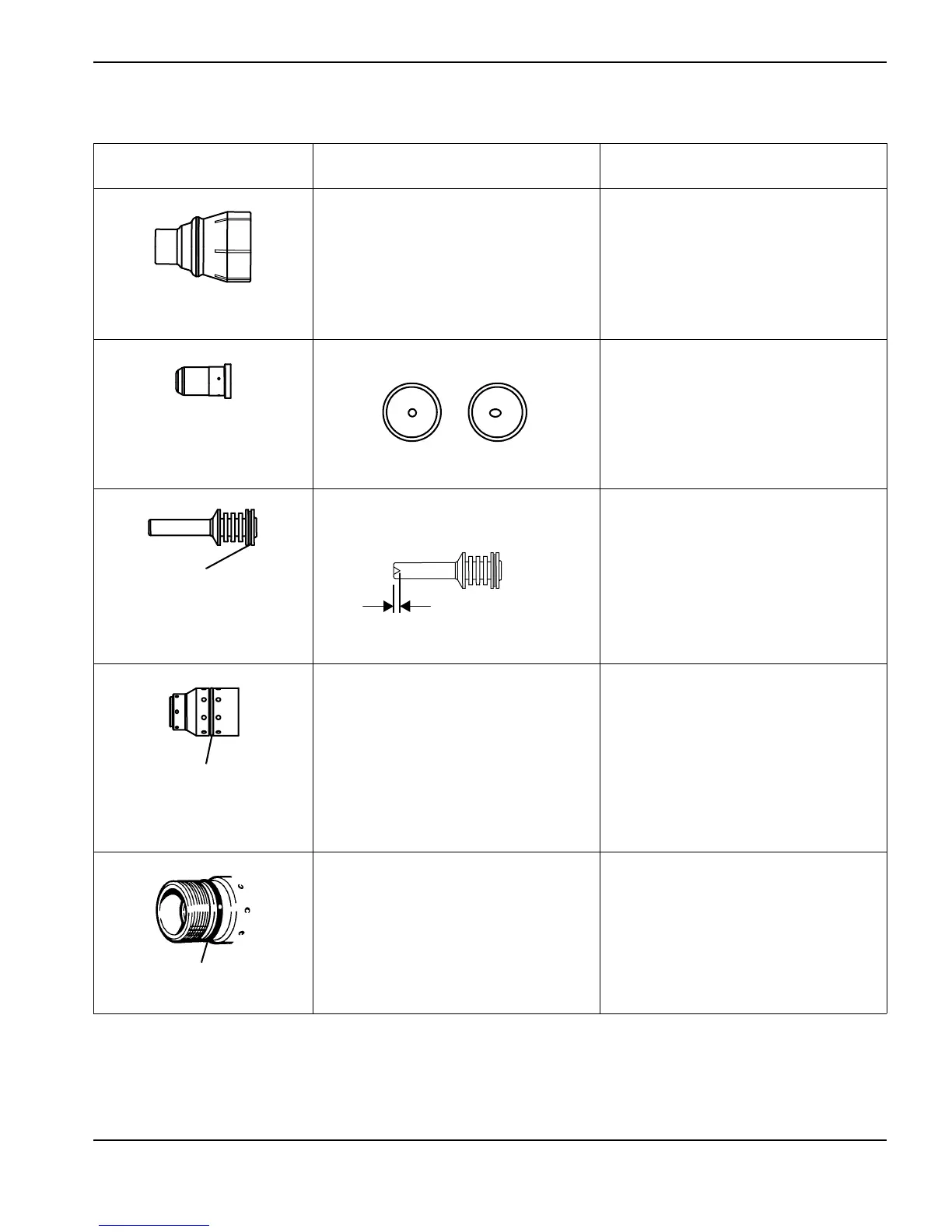

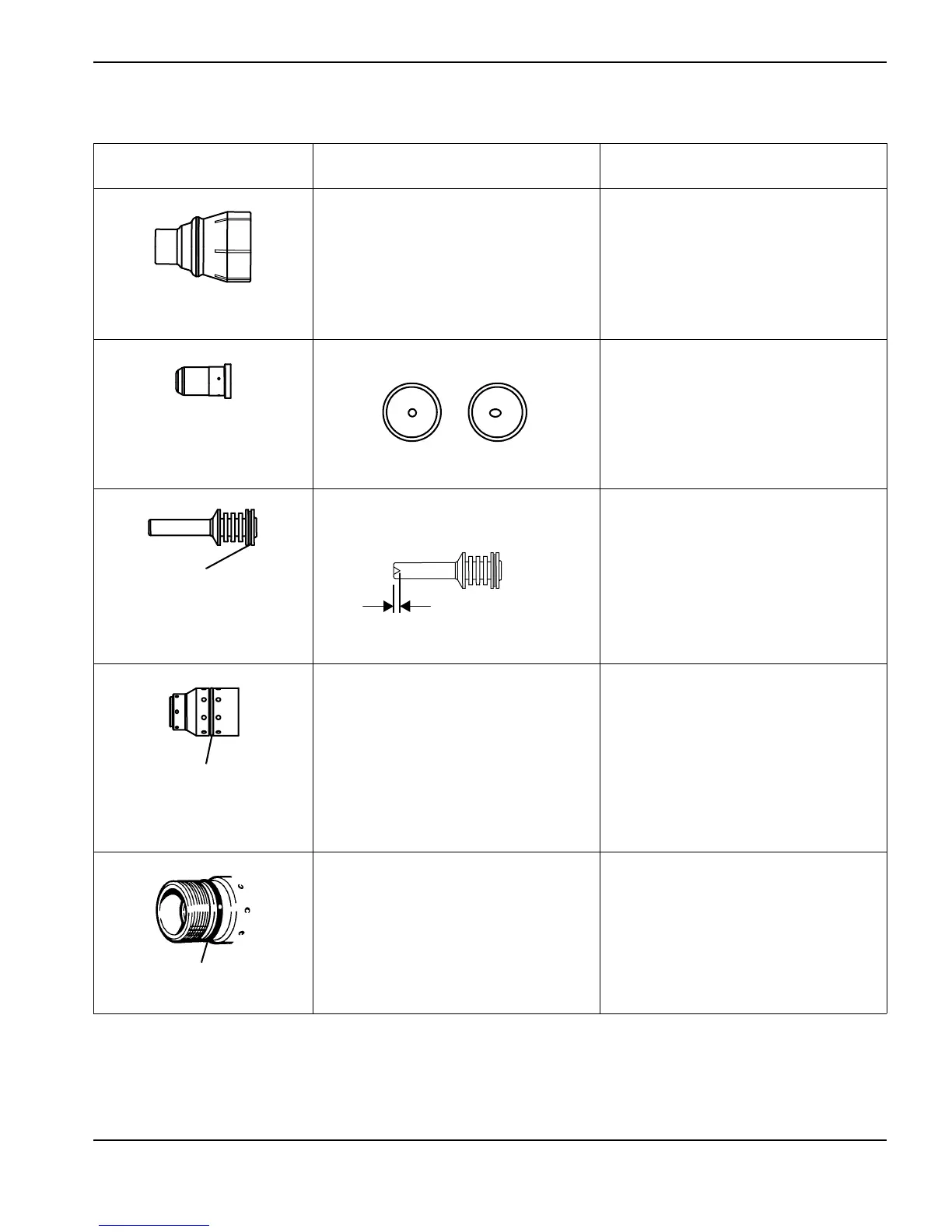

Part Inspect Action

Deflector

The center hole for roundness.

The rounded edges of the center hole

for damage or noticeable wear.

Replace the deflector if the hole is no

longer round or if it is worn or

damaged.

The gap between the nozzle and the

deflector for accumulated debris.

Remove the deflector and clean any

material away.

Nozzle

The center hole for roundness. Replace if the center hole is not round.

Replace the nozzle and the electrode

together.

Electrode

The center surface for wear and verify

the pit depth.

Replace if the surface is severely worn

or the pit depth is greater than 1.6 mm

(1/16 inch) deep. Replace the nozzle

and the electrode together.

Do not apply grease or other lubricants

to the O-ring on the electrode.

Swirl ring

The internal surface for damage or

wear and the gas holes for blockages.

Replace if the surface is damaged or

worn or any of the gas holes are

blocked.

Do not apply grease or other lubricants

to the O-ring on the swirl ring.

The length of the swirl ring. If the length of the swirl ring is less than

21 mm (0.83 inches), replace it.

Torch O-ring

The surface for damage, wear, or a lack

of lubrication.

If the torch O-ring is dry, apply a thin

film of silicone lubricant on the O-ring

and the threads. The O-ring should

look shiny, but there should not be any

excess or built-up lubricant.

If the O-ring is cracked or worn,

replace it.

Maximum 1.6 mm

(1/16 inch)

Loading...

Loading...