20

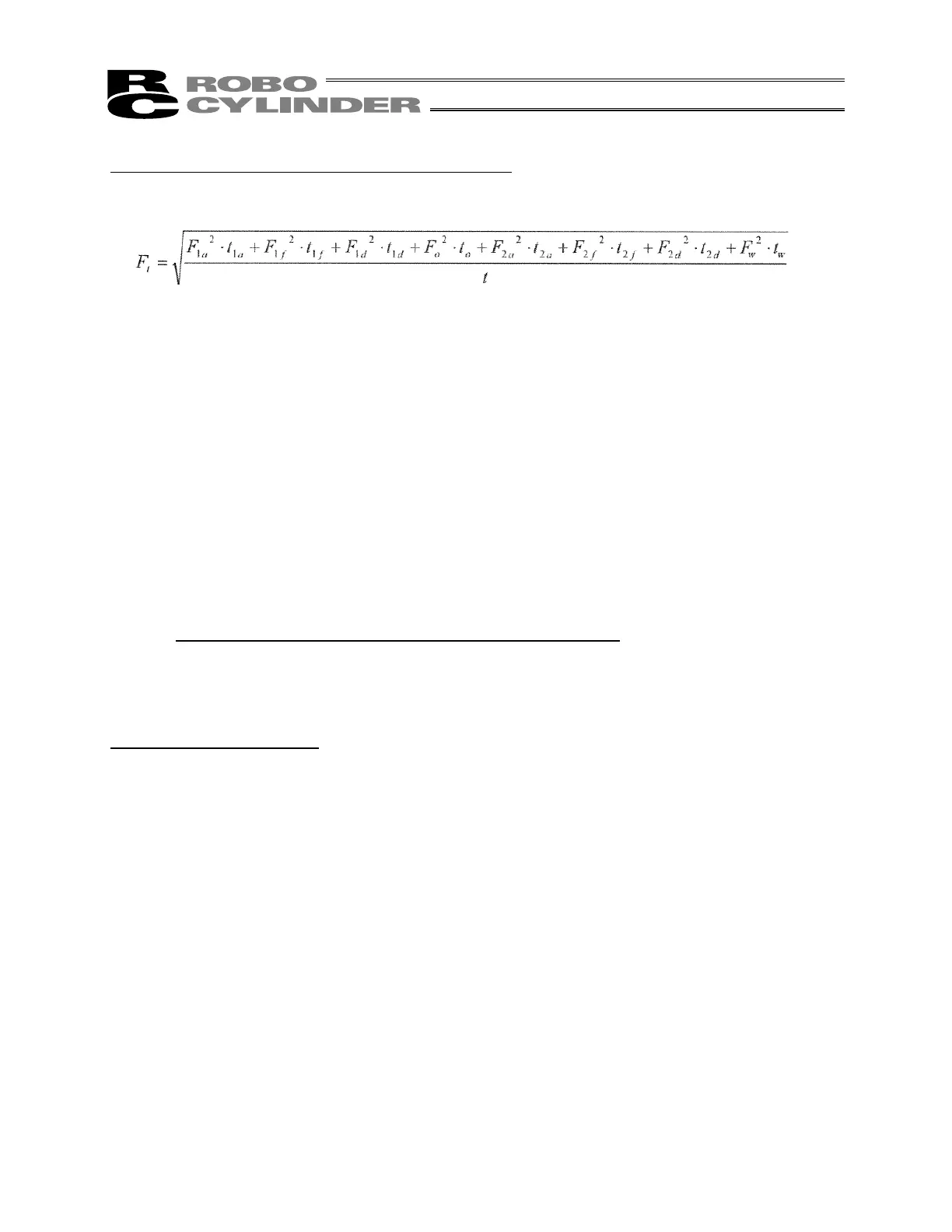

Condition [2] Calculate the thrust for continuous operation.

Assign the above operation pattern to the aforementioned formula to calculate thrust for continuous

operation.

Here,

F

1a

, F

2d

= (M + m) x 9.8 - (M + m) x d = 1058 N

F

1f

, F

2f

= (M + m) x 9.8 = 1068N

F

1d

, F

2a

= (M + m) x 9.8 + (M + m) x d = 1079 N

F

0

= Push command value 200% (2000 kgf) = 19600 N

F

w

= (M + m) x 9.8 = 1068N

t

1a

= t

2a

= t

1d

= t

2d

= Speed 62 mm/s ÷ Acceleration/deceleration 98 mm/s

2

= 0.632 s

t

1f

= t

2f

= (Travel distance 50 mm – (Travel distance during acceleration 19.60 mm + Travel distance during

deceleration 19.60 mm)) ÷ Speed 62 mm/s = 0.174 s

Travel distance during acceleration (deceleration) = Acceleration (deceleration) rate 98 mm/s

2

x

(Acceleration (deceleration) time (t

1a

,

2a

,

1d

,

2d

) 0.632 s)

2

÷ 2 = 19.60 mm

t

o

= 3s, t

w

= 2 s, t = 7.88 s

From the above, the following result is obtained:

F

w

= 12113 N

Since this is greater than the rated thrust of 10200 N specified for the ultra high-thrust actuator with 1.25

(2t) lead, the actuator cannot be operated based on this operation pattern.

Now, the standby time is increased (duty is lowered) as a countermeasure.

In this example, calculations are repeated by assuming t

1

= 6.12 s (t = 12 s). This time, the following result

is obtained:

F

w

= 9814 N

The actuator can be operated.

Loading...

Loading...