21

13. Maintenance

13.1 Maintenance Schedule

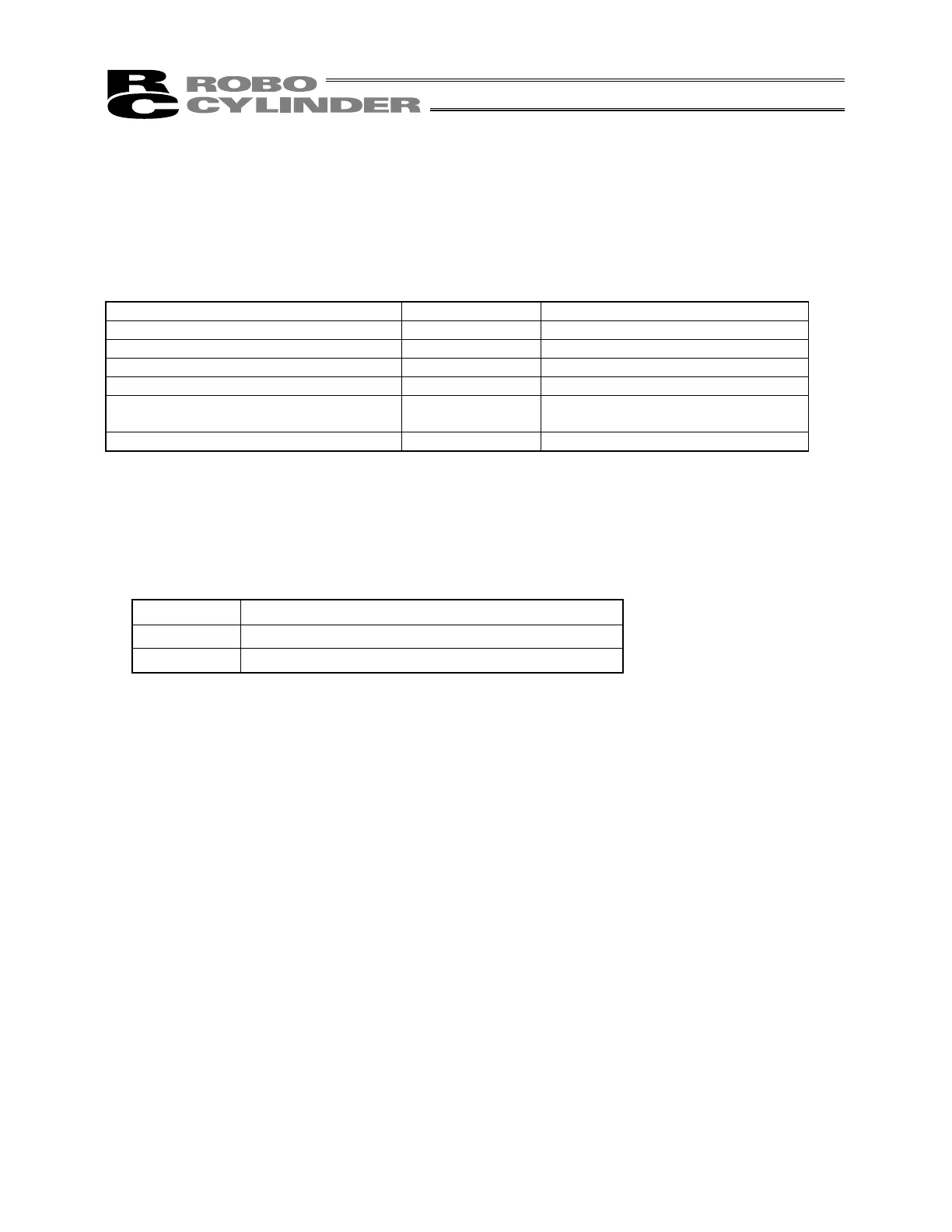

Perform maintenance work according to the schedule below.

The schedule is set assuming eight hours of operation a day. When the operation time is long such as 24-

hour operation, shorten the maintenance intervals as needed.

Visual inspection Grease supply

Start of operation

{

After 1 month of operation

{

After 3 months of operation

{

{ (Rod (ball spline) slide surface) *1

Every 3 months thereafter

{

{ (Rod (ball spline) slide surface) *1

After 3 years of operation or 5000 km

travel distance

{

Every 1 year thereafter

{

*1 Apply the grease to the rod (ball spline) slide surface when dry surface is observed at the start of

operation or every three months of operation.

13.2 Visual Inspection of the Machine Exterior

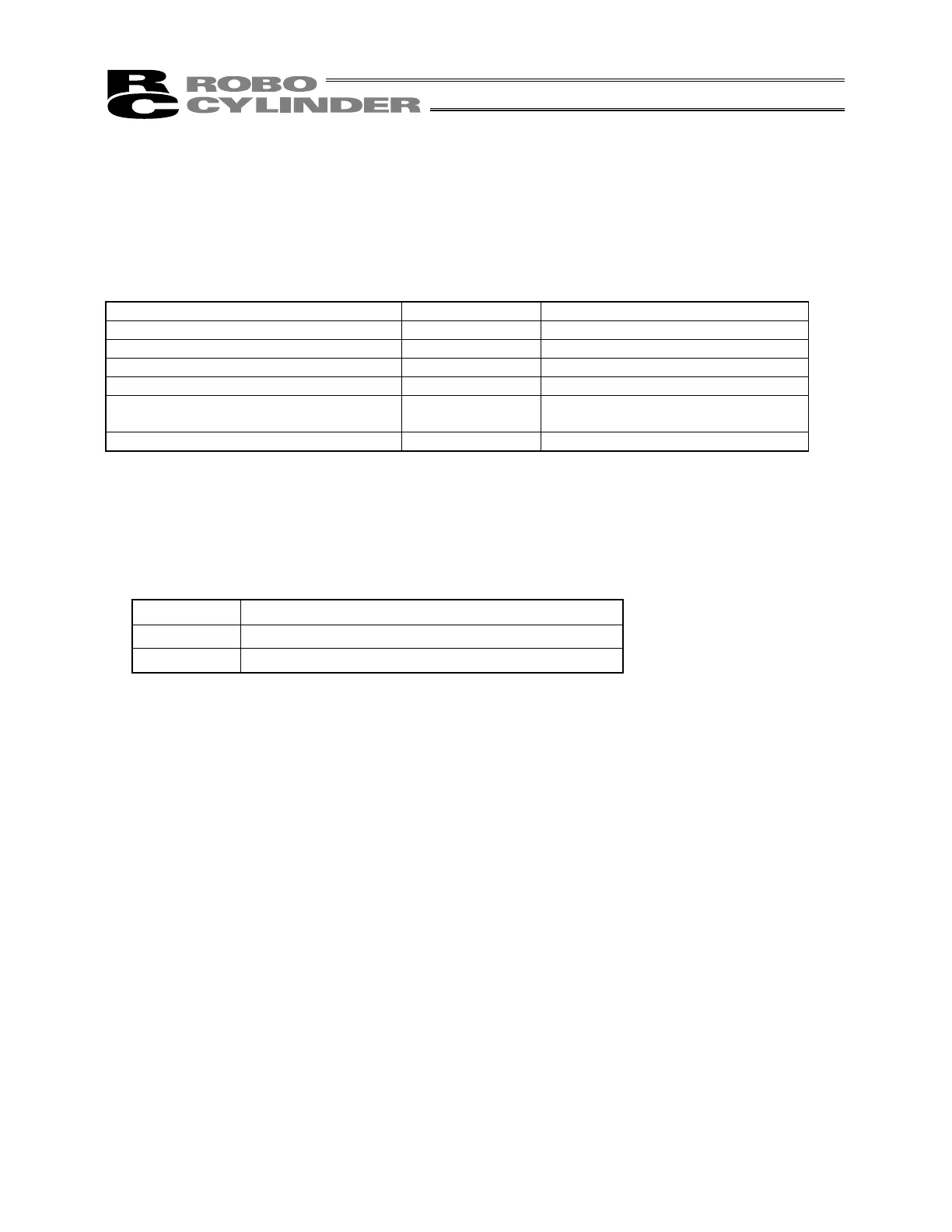

Check the following when doing the visual inspection.

Body Loose mounting bolts?

Cables Damage to cables or connection to connector box?

General Unusual noise or vibrations?

13.3 Cleaning

• Clean the exterior as needed.

• Wipe off dirt with a soft cloth.

• Do not use strong compressed air on the actuator, as it may force dust into the crevices.

• Do not use petroleum-based solvents, as they may damage resin or coated surfaces.

• If the unit is badly soiled, apply a neutral detergent or alcohol to a soft cloth and wipe lightly.

Loading...

Loading...