MAN-045 ING

12

b.

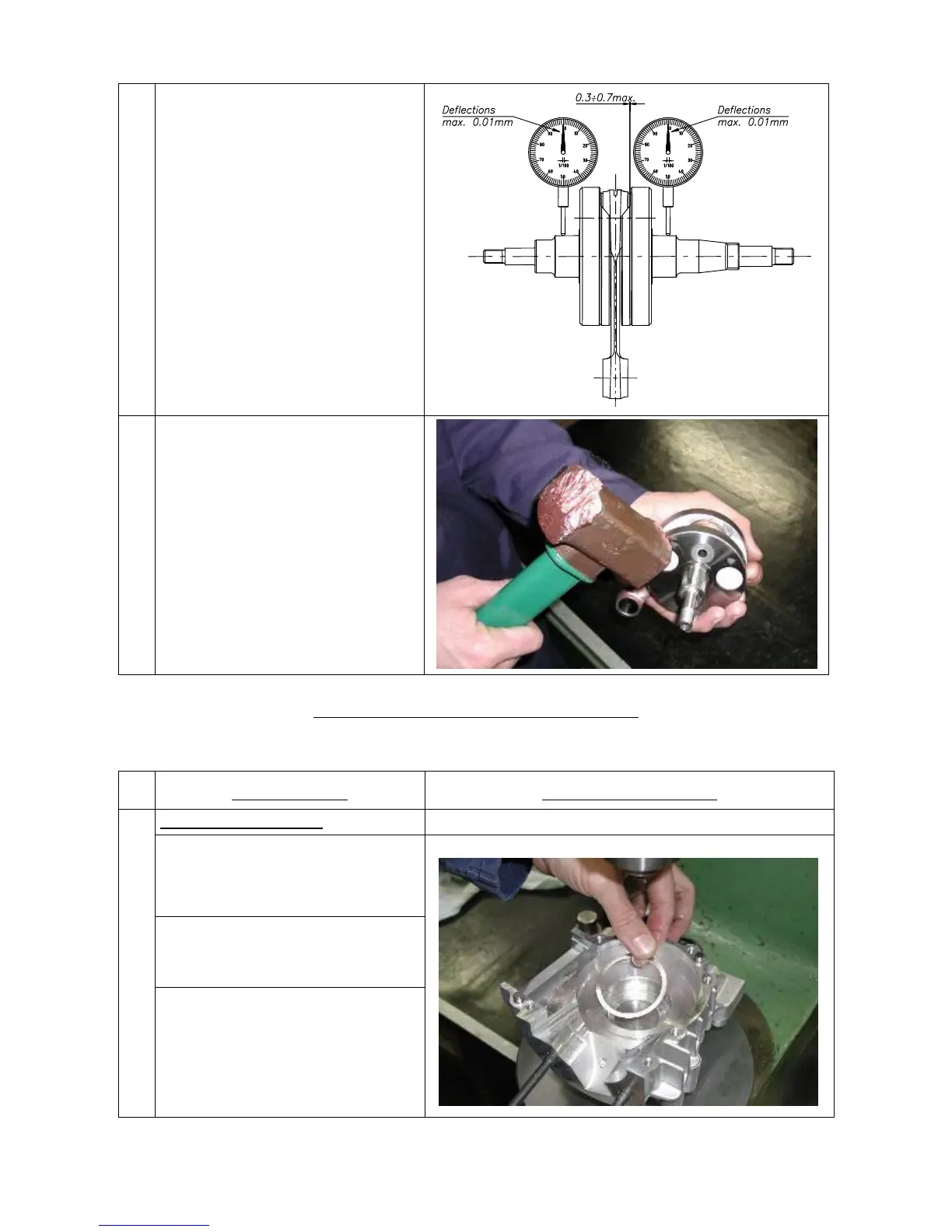

ROTATE CRANKSHAFT AND LOOK AT

DEFLECTION OF GAUGE NEEDLES.

DEFLECTION MUST BE, AFTER CENTERING

MAX. 0.01mm (see drawing).

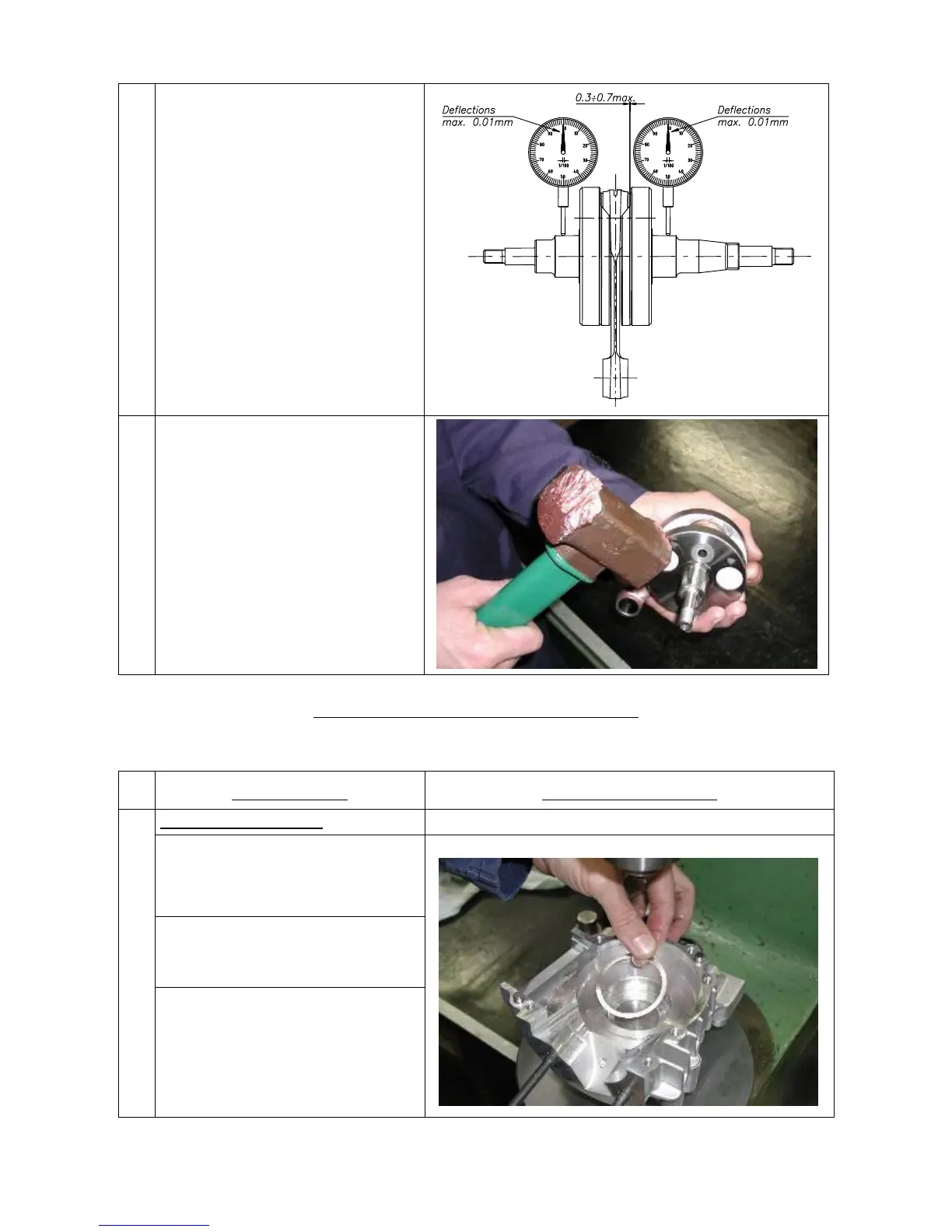

c.

ADJUST CENTERING WITH COPPER

HAMMER, IF NECESSARY

(see Fig.11).

3 – ENGINE ASSEMBLING

BEFORE REASSEMBLING, WASH ALL THE PARTS WITH KEROSENE

OPERATION

TOOLS REQUIRED

CRANKCASE REASSEMBLY:

a) CHECK STATUS OF CRANKCASE

BEARING.

VISUAL CHECK.

REPLACE AFTER 6 HRS MAX.

b) PLACE CRANKCASE HALVES UNDER

THE PRESS (OR HEAT CRANKCASE

HALF AT 70°C).

1.

c) INSERT BEARING SHIMS

(see Fig.1).

Fi

Loading...

Loading...