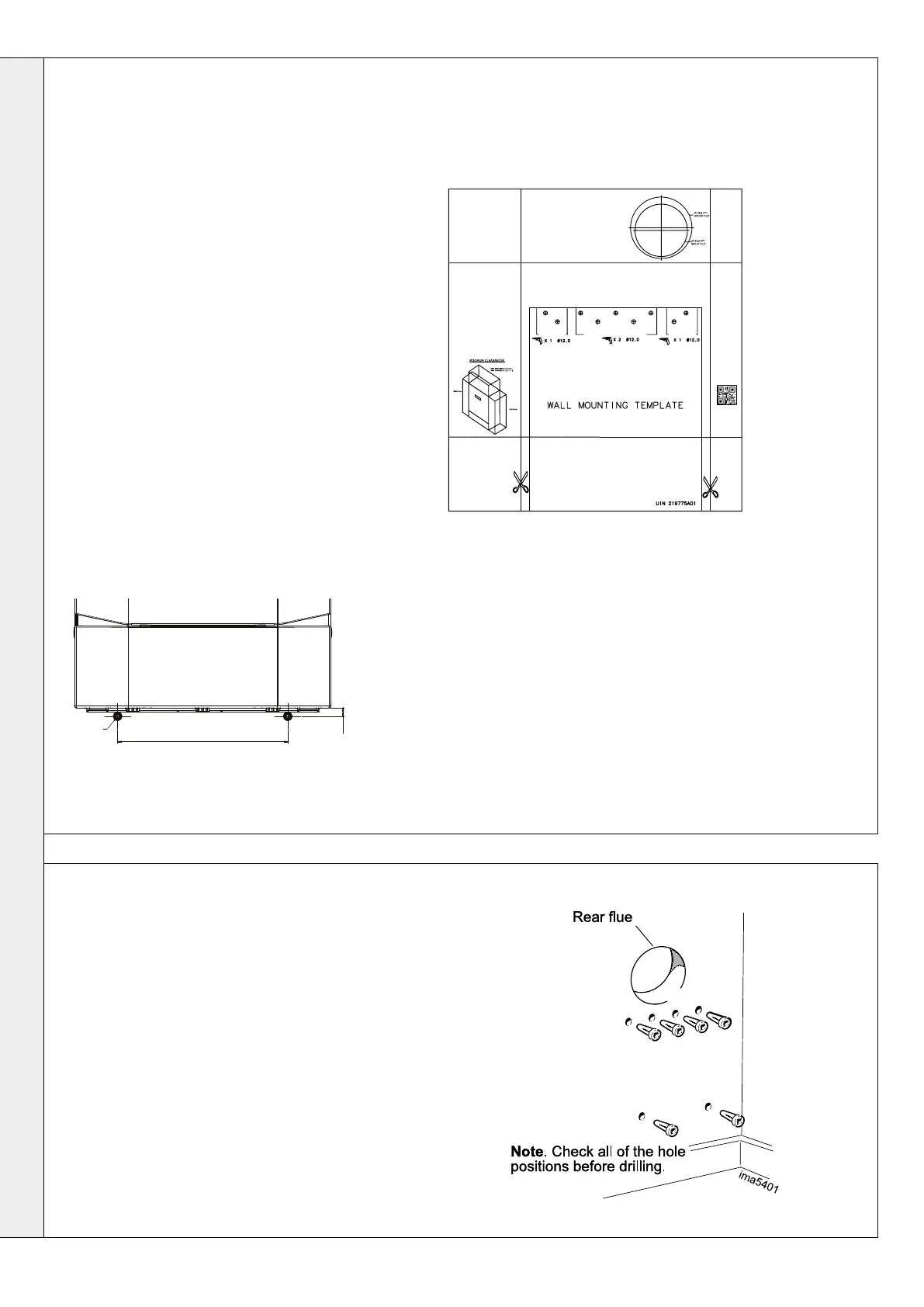

2.4 WALL MOUNTING TEMPLATE

2.5 PREPARING THE WALL

Note. The template shows the positions for the

top xing holes. Care must be taken to ensure

the correct holes are drilled.

1. Tape template into the selected position.

2. Ensure squareness by hanging a plumbline.

3. Mark on to the wall:

a. The top 4 wall mounting plate screw

positions.

b. The 2 boiler lower xing positions using

diagram below

c. The position of the ue duct. Mark

the centre of the hole as well as the

circumference.

4. Remove the template from the wall.

IMPORTANT. The wall must be vertical 90º (±5º)

from the perpendicular to allow safe operation of

the integral ue non return valve.

Ensure that, during the cutting operation, masonry

falling outside of the building does not cause

damage or personal injury.

1. Cut the ue hole ensuring that the hole

is square to the wall. Both wall faces

immediately around the cut hole should be at.

2. Drill 4 boiler top xing holes with a 12mm

masonry drill and insert the plastic plugs

provided, for the wall mounting plate.

3. Drill the 2 boiler lower xing holes with a 12mm

masonry drill, insert the plastic plugs provided .

4. Fix the wall bracket into place with 4 M10x70

hex head coach screws provided.

Note: Horizontal ue runs must be

inclined at 1.5-3

o

to the horizontal to allow

condensate to drain back to the boiler.

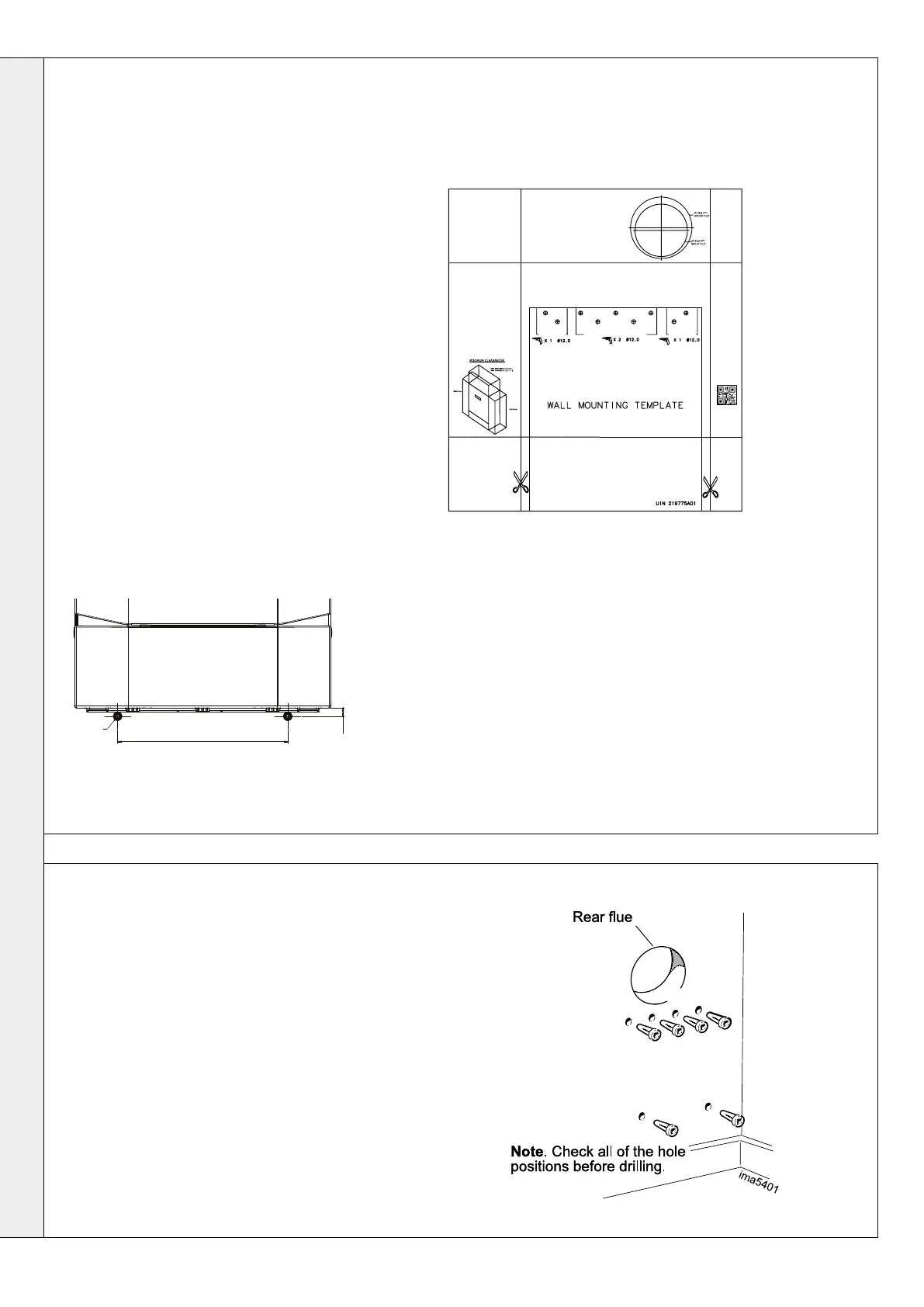

BOILER LOWER FIXING POSITIONS

mm332

Ø12mm

850mm to top of boiler

mm17

B

16

Installation & Servicing

SECTION 2 - INSTALLATION

INSTALLATION

Loading...

Loading...