2.6 MOUNTING THE BOILER

2.7 VENTILATION

The ventilation requirements of these boilers is dependant on

the type of ue system used, and their heat input. All vents must

be permanent with no means of closing, and positioned to avoid

accidental obstruction by blocking or ooding.

30/30P, 40/40P, 60/60P

Detail reference should be made to BS. 5440 Pt. 2. In IE refer to

the current edition of I.S. 813.

The following notes are for general guidance only:

If installed as a room sealed appliance in a room or internal

space, then no purpose provided ventilation is required.

If installed as an open ued appliance in a room or internal space

then a permanent air vent is required. The sizes given below are for

vents directly communicating with outside air. For other situations

refer to BS. 5440 Pt. 2. In IE refer to the current edition of I.S. 813.

Boiler Size 30 & 30P 40 & 40P 60 & 60P

Minimum vent

free area (cm

2

)

117 167 269

If installed in a compartment, then permanent air vents are

required at high and low level. These vents may communicate

direct to outside air, or to a room/internal space. If to a room/

internal space, it must itself be adequately ventilated as above.

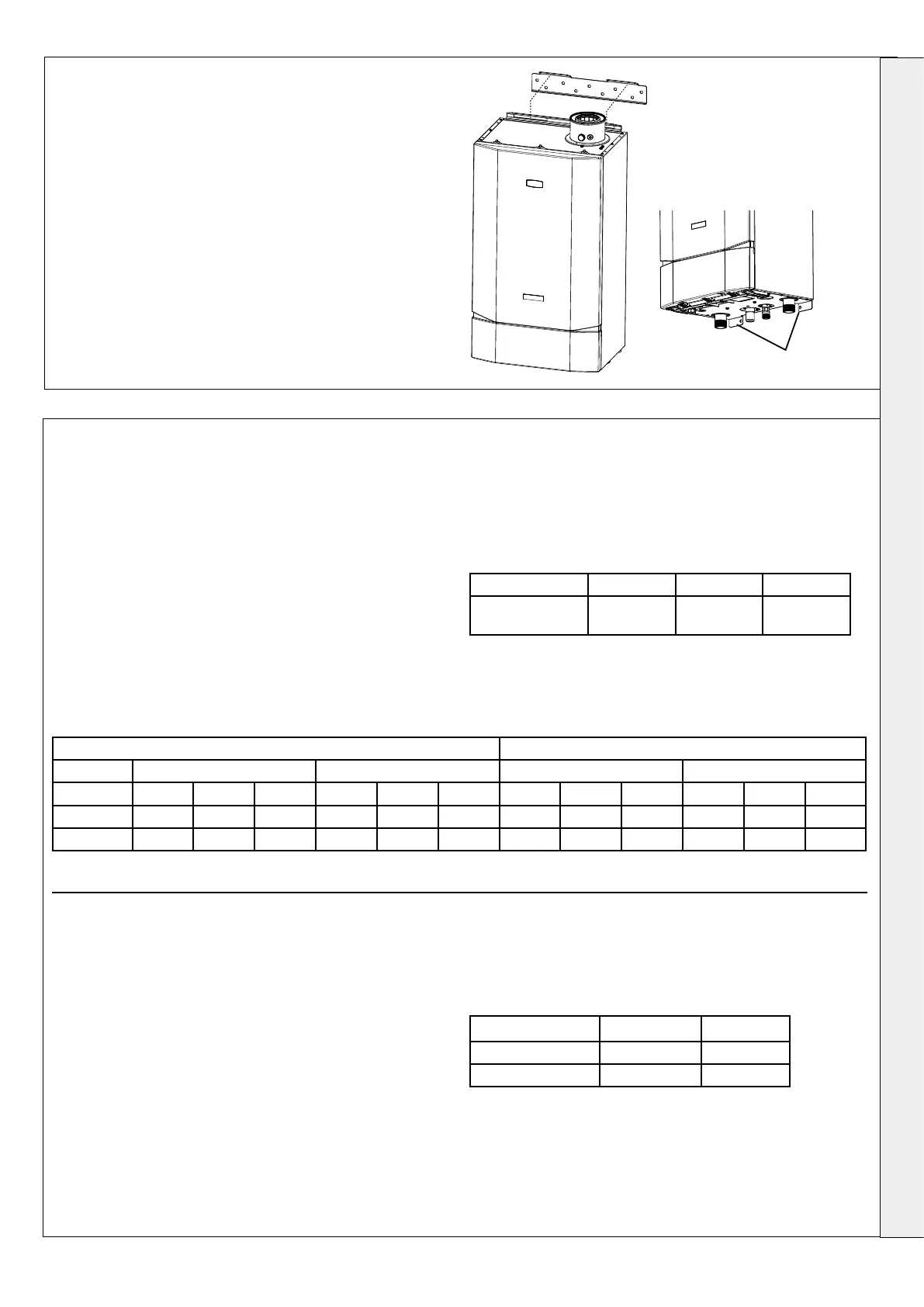

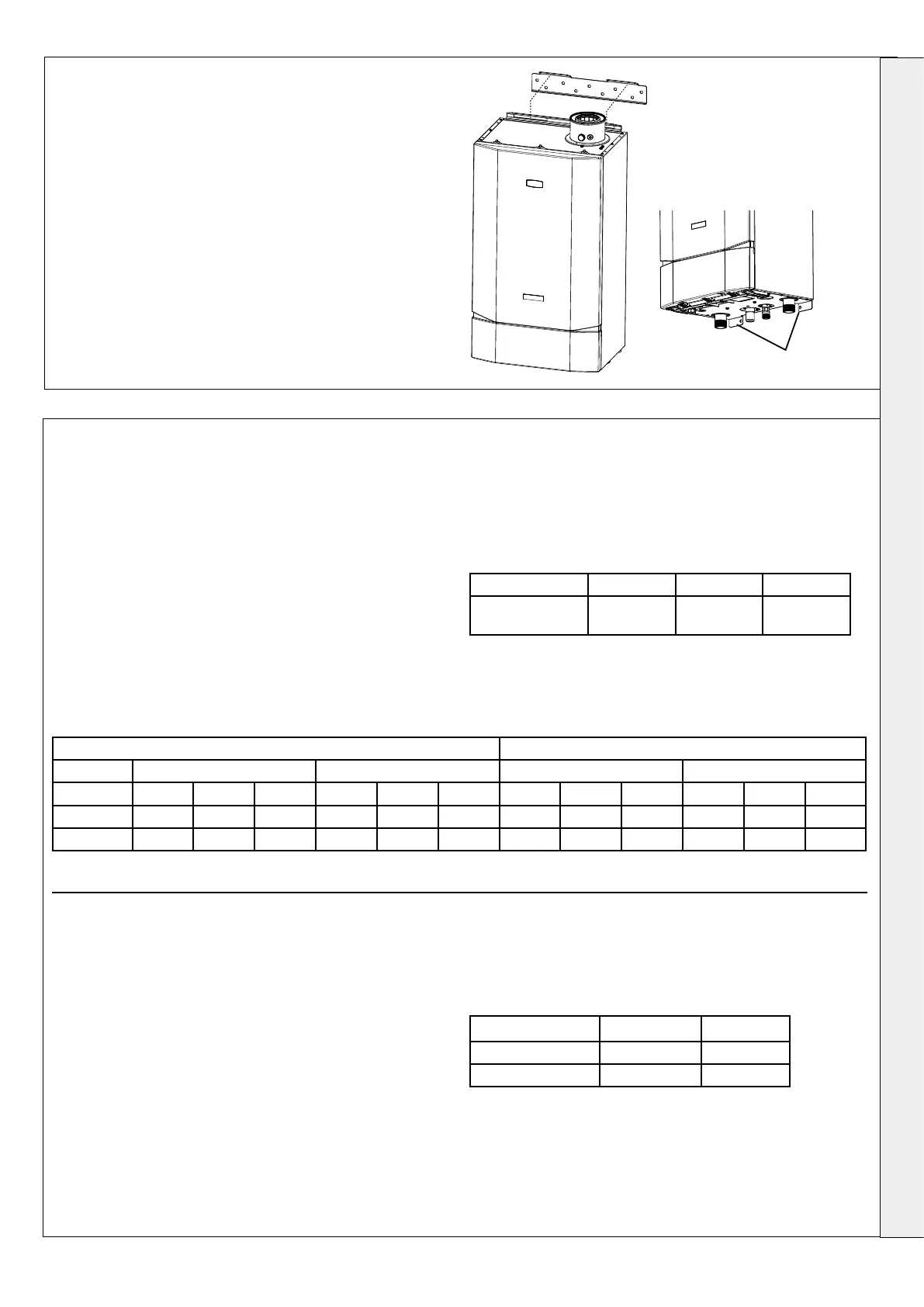

• Due care should be taken when lifting the boilers, with

respect to their weights, see Table 2 on Page 6. Also

refer to Section 1.4 Safe Handling.

1. Lift the boiler onto the wall mounting plate as shown.

Note: It is not necessary to hold the boiler at an angle

to engage the wall mounting plate.

2. Using the remaining coach screws, secure the bottom

of the boiler to the wall through the attached brackets.

IMPORTANT NOTE It is essential that these bolts be

tted prior to making up the ow and return connections to

the boiler to prevent the boiler becoming detached .

The temperature within the boiler room shall not exceed 25ºC within 100mm of the oor, 32ºC at mid height and 40ºC within 100mm

of the ceiling.

BOILERS 70kW AND OVER

80, 80P, 100, 100P, 120, 120P, 150 and multiple boiler

applications

Detail reference should be made to BS. 6644 and IGEM/UP/10

for inputs between 70kW and 1.8MW (net). In IE refer to the

current edition of I.S.820. The following notes are for general

guidance only:

If ventilation is to be provided by means of permanent high and

low vents communicating direct with outside air, then reference

can be made to the sizes below. For other ventilation options

refer to BS. 6644 and IGEM/UP/10. In IE refer to the current

edition of I.S.820.

80, 80P, 100, 100P, 120, 120P & 150

Open Flued Installations

Required area (cm

2

) per kW of total rated input (net)

Boiler Room Enclosure

Low level (inlet) 4 10

High level (outlet) 2 5

Note: Where a boiler installation is to operate in summer months (e.g.

DHW) additional ventilation requirements are stated, if operating for

more than 50% of time (refer to BS6644) and IGEM/UP/10.

Room Sealed Installations

A minimum of 2cm

2

free area per kW of net heat input at both

high and low level is required for boiler rooms. For enclosures

refer to BS6644 and IGEM/UP/10.

Room Sealed Application - Min. Vent Free Area (cm

2

) Open Flue Application - Min. Vent Free Area (cm

2

)

To a room or internal space To outside Air To a room or internal space To Outside Air

Boiler Size 30 40 60 30 40 60 30 40 60 30 40 60

High Level 310 410 610 155 205 305 310 410 610 155 205 305

Low level 310 410 610 155 205 305 620 820 1220 310 410 610

Ventilation Requirements (not exceeding 70kW net Input) when installed in a compartment

BOILERS NOT EXCEEDING 70kW

17

Installation & Servicing

SECTION 2 - INSTALLATION

INSTALLATION

Loading...

Loading...