11

UK

5 Installation

Before installing and removing the unit: Make sure that no pressure is

applied to the system and there is no medium in the pipe� Also always

note the potential dangers related to extreme machine or medium

temperatures�

5.1 Installation location / environment

• Installation preferably in closed, metal tanks or pipes�

• The sensor must be in electrical contact with the metal process connection�

When installed in plastic tanks, there may be deterioration caused by

electromagnetic interference�

► Check the function by an application test�

► If disturbances occur, appropriate measures must be taken

(shielding, grounding, etc )

A correct fit and function of the unit and ingress resistance of the

connection are only ensured using ifm adapters�

For use of process connections from other manufacturers:

► Ensure mechanical compatibility�

As a rule, ifm does not assume any responsibility for ingress resistance,

hygiene and function, in particular with non-existing compatibility and

incorrect installation�

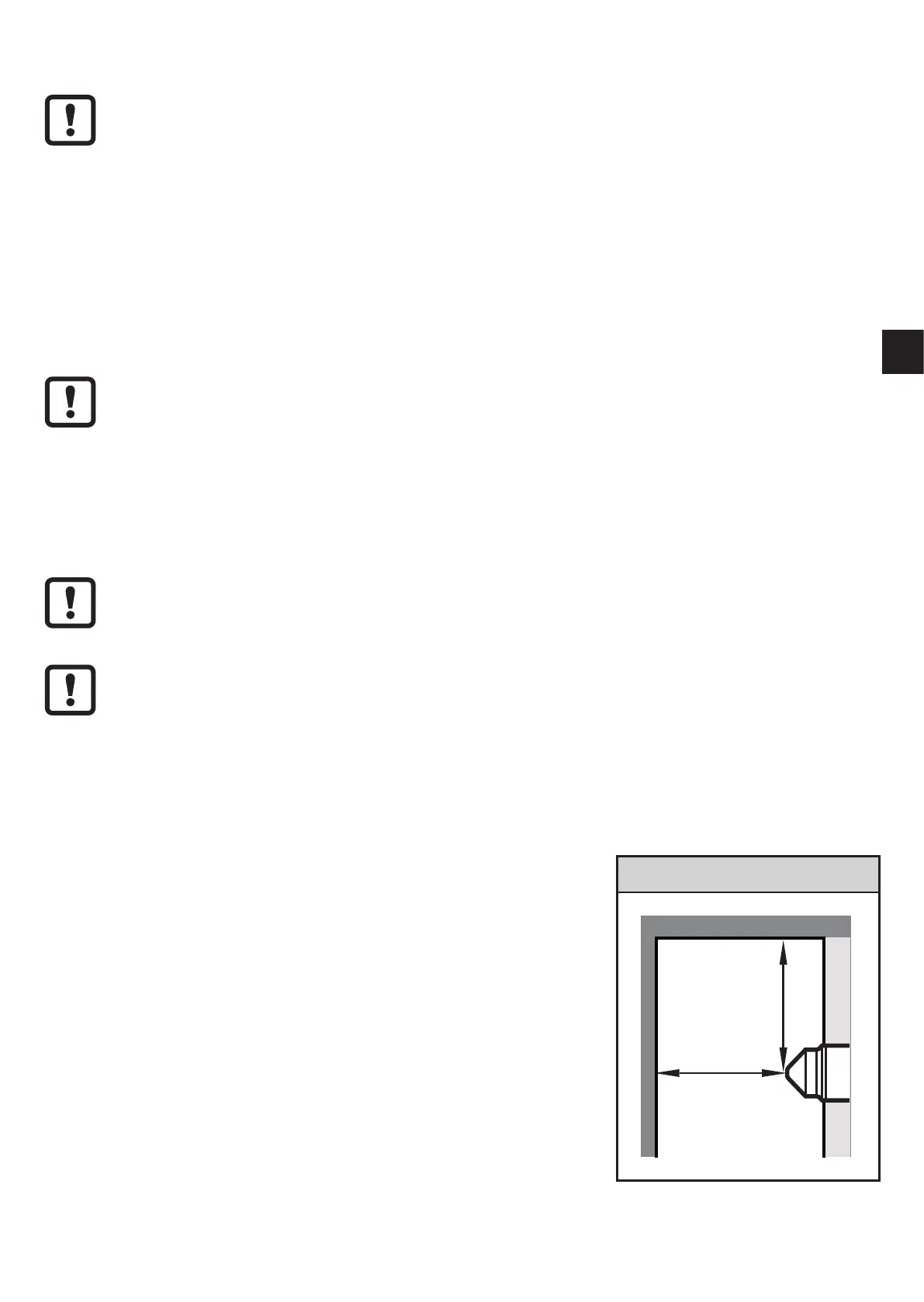

When installed in restricted spaces (e�g� pipes, tank

corners, structures) or in agitators and other moving

objects:

► To avoid malfunction and damage on sensor

and plant, adhere to a distance of min� 15 mm

to neighbouring objects (e�g� pipe/tank walls,

structures, other sensors) (fig� 6-1)�

Fig. 6-1

15 mm

15 mm

Loading...

Loading...