1-27

1-28

18 - IE

INSTALLERUSER

MAINTENANCE TECHNICIAN

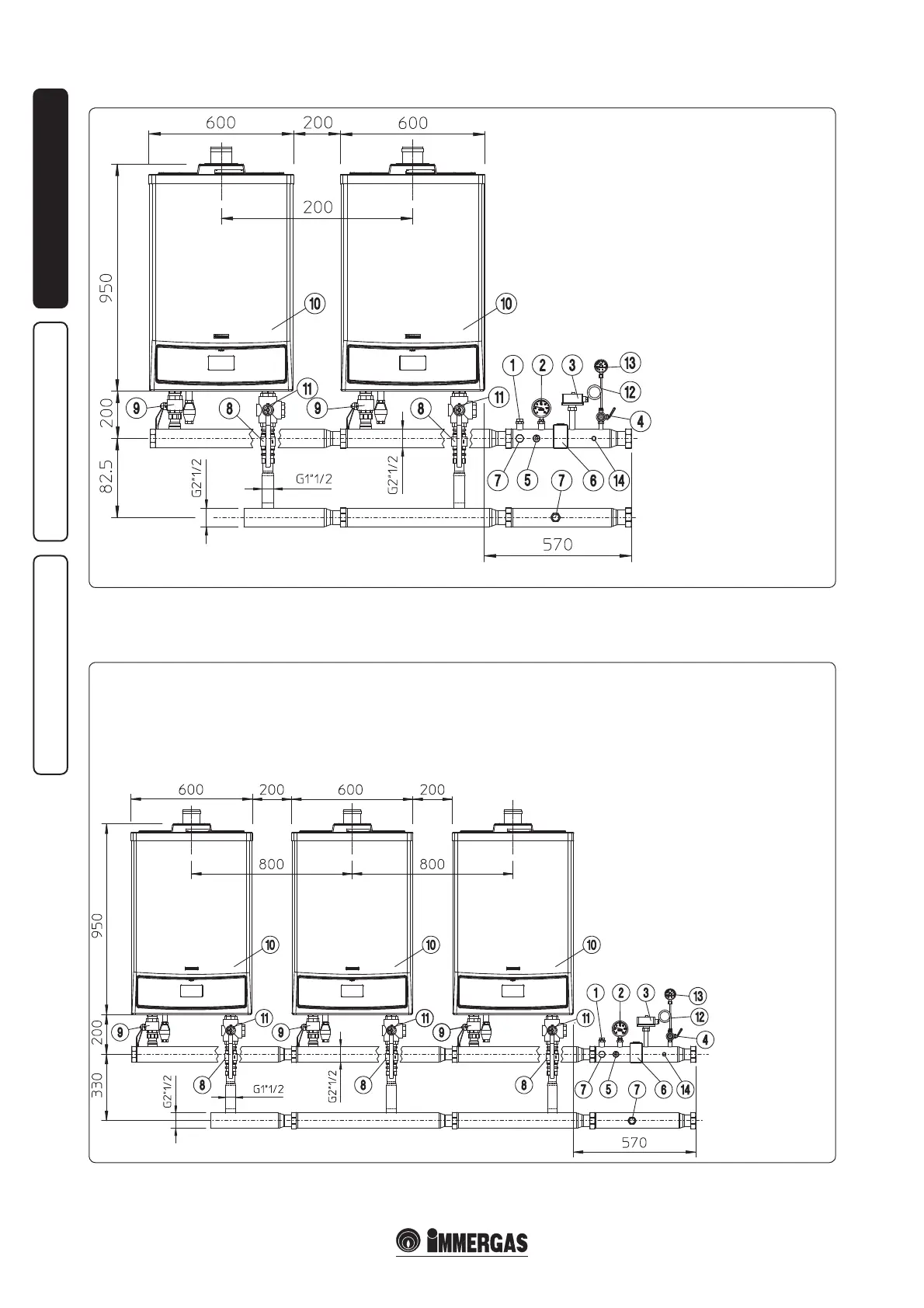

1.22 HYDRAULIC DIAGRAM FOR NO. 2 BOILERS IN CASCADE WITH OPTIONAL.

Attention: the modular boilers, i.e. installed

in cascade (set) with an Immergas original

Key:

1 - ermometer pocket

2 - ermometer

3 - Manual rearm thermostat

4 - Manometer-holder cock

5 - Probe for fuel shut-o valve bulb

6 - Manual rearm pressure switch

7 - Attachment for expansion vessel

8 - System return non-return valve

9 - System cut-o valves

10 - Generator

11 - ree-way draining valve

12 - Damper coil

13 - Manometer

14 - Connection for minimum pressure switch

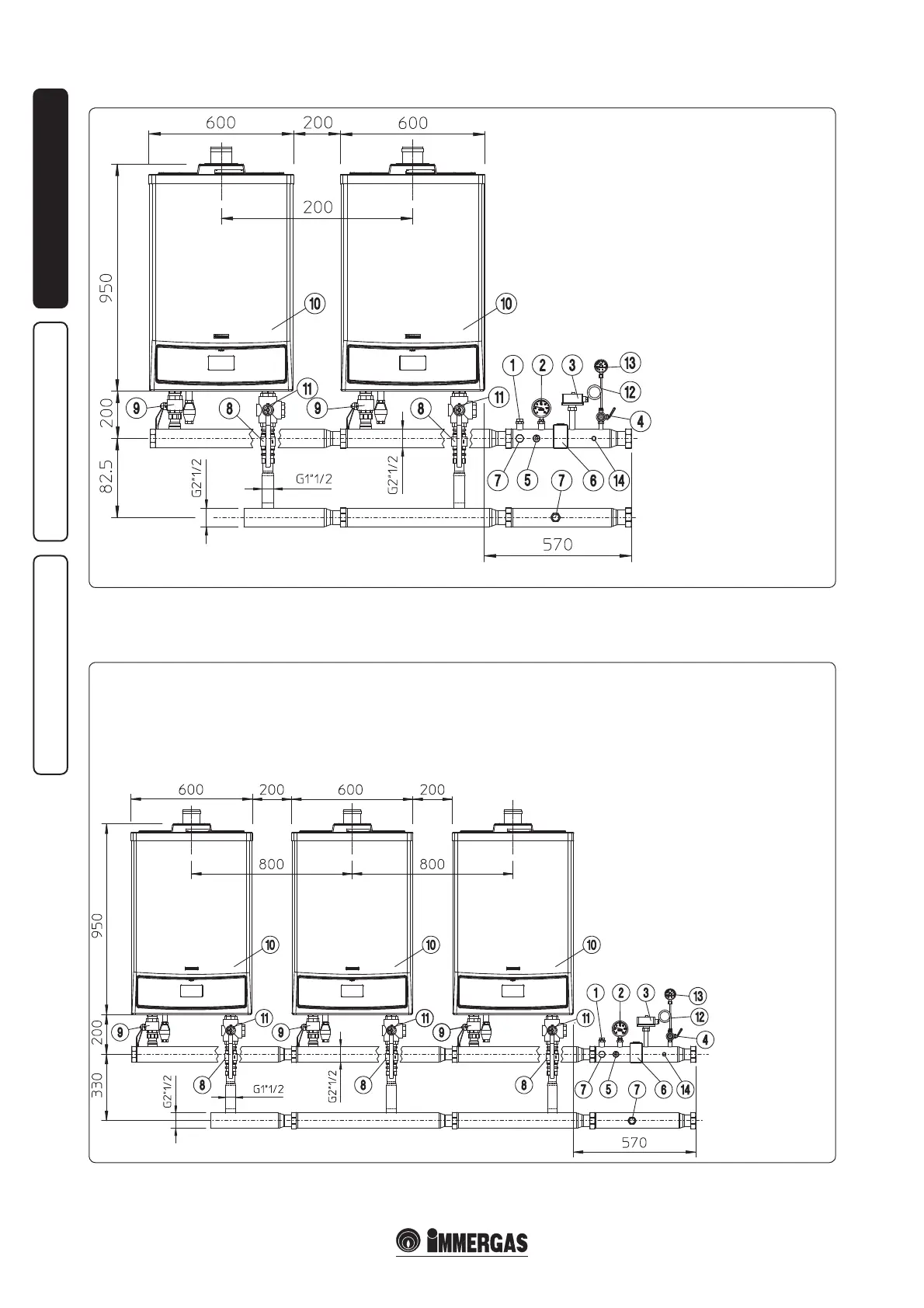

1.23 HYDRAULIC DIAGRAM FOR NO. 3 BOILERS IN CASCADE WITH OPTIONAL.

Attention: the modular boilers, i.e. installed

in cascade (set) with an Immergas original

connection kit, must be considered a unique

appliance, which assumes the serial number

(factory number) of the boiler nearest to the

safety devices.

Key:

1 - ermometer pocket

2 - ermometer

3 - Manual rearm thermostat

4 - Manometer-holder cock

5 - Probe for fuel shut-o valve bulb

6 - Manual rearm pressure switch

7 - Attachment for expansion vessel

8 - System return non-return valve

9 - System cut-o valves

10 - Generator

11 - ree-way draining valve

12 - Damper coil

13 - Manometer

14 - Connection for minimum pressure

switch

connection kit, must be considered a unique

appliance, which assumes the serial number

N.B.: before closing one or both the system cut-

o cocks (9), the boiler must be switched o.

(factory number) of the boiler nearest to the

safety devices.

Loading...

Loading...