28 - IE

INSTALLERUSER

MAINTENANCE TECHNICIAN

For example, if these values are

read on the display it means

that the appliance is in ignition

3.5 FUNCTIONING ANOMALIES WITH ELECTRIC REARM.

For example, if these values

are read on the display it

means that the appliance

has a temperature dierence

(∆t) between system ow and return greater

than 40°C. e blocks are temporary and the

boiler rearms automatically when the anomaly

disappears.

N.B.: maintenance interventions must be carried

out by a qualified technician (e.g. Immergas

Aer-Sales Technical Assistance Service).

- Smell of gas. Caused by leakage from gas circuit

pipelines. Check sealing eciency of gas intake

circuit.

- Irregular combustion or noisiness. is may be

caused by: a dirty burner, incorrect combustion

parameters, intake-exhaust terminal not

correctly installed. Clean the above components

and ensure correct installation of the terminal,

check correct setting of the gas valve (O-Set

setting) and correct percentage of CO

2

in ue

gases.

- Siphon blocked. is may be caused by dirt or

combustion products deposited inside. Check,

by means of the condensate drain cap, that

there are no residues of material blocking the

ow of condensate.

- Heat exchanger blocked. is may be caused

by the trap being blocked. Check, by means of

the condensate drain cap, (accessible only aer

the casing front has been removed) that there

are no residues of material blocking the ow of

condensate.

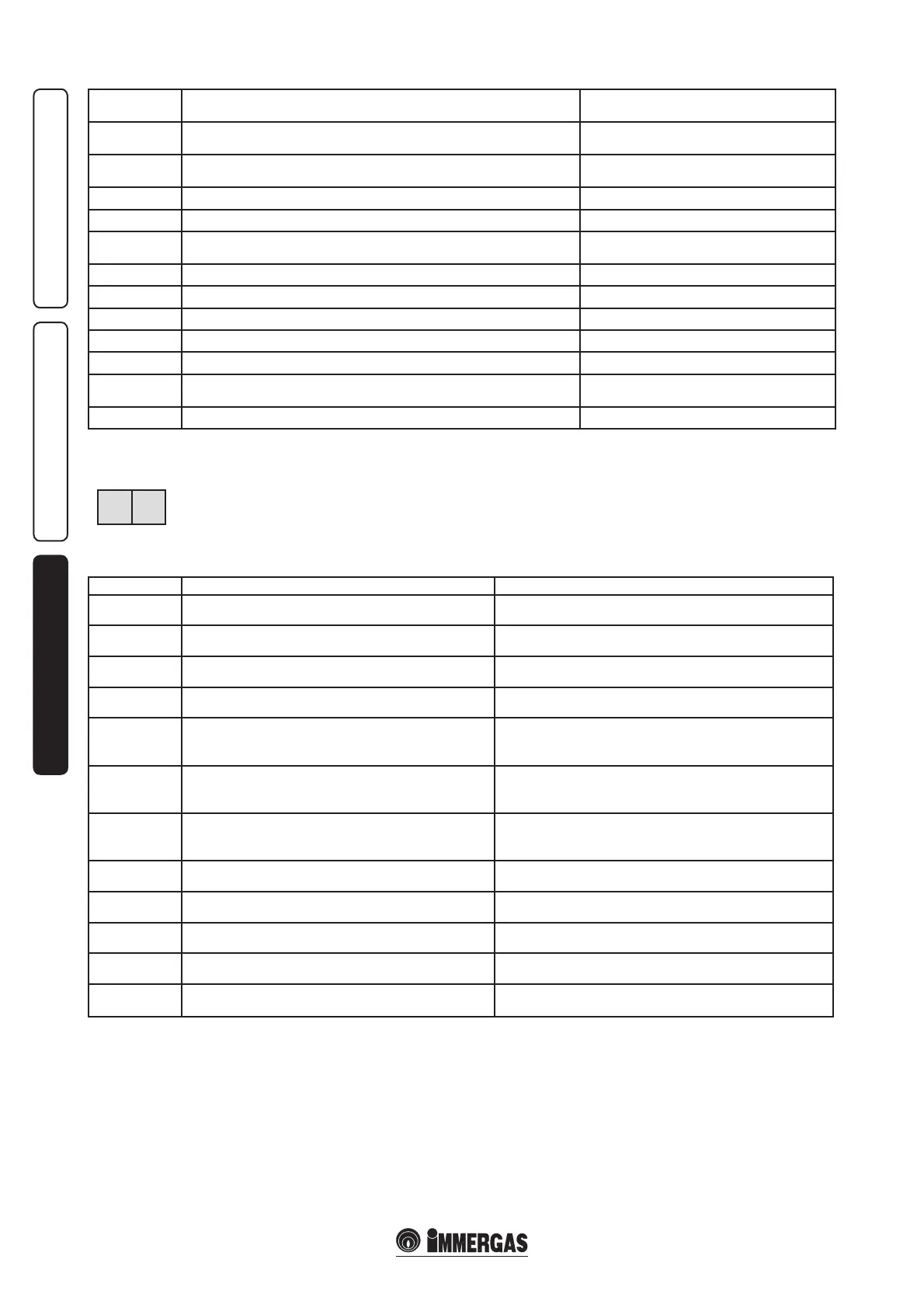

E 02

Code Description Remedy

b 18 System ow temperature over 92°C Check the circulation of water in the system

b 19 System return temperature over 87°C Check the circulation of water in the system

b 24 Inverted ow return probes Check probes position

b 25 Increase of the system ow temperature too quick Check the circulation of water in the system

b 26 No water/Water pressure insucient

Check the correct water pressure inside the system

Take the water pressure in the system to a value between 1 and 1.2 bar

Check for any leaks in the circuit

b 28 Fan breakdown (no Hall signal)

Check fan

Check fuse "F3"

Check P.C.B.

b 29 Fan fault

Check fan

Check fuse "F3"

Check P.C.B.

b 30 Temperature dierence between system ow greater than 40°C Check the circulation of water in the system

b 33 DHW probe anomaly (short circuit) Check/replace DHW probe

b 38 DHW probe anomaly (open) Check/replace DHW probe

b 65 Fan start stand-by (insucient air ow rate) Check fan functioning

b 118

Ionisation current loss during burner ignition (aer 3 attempts

becomes "02" error ignition block)

Check presence of gas and electric power supply

Check the gas supply pressure

E 12 over-temperature safety thermostat intervention or ue safety thermostat intervention

Check water overheating thermostat

Check ue safety thermostat

E 13 Error detected in P.C.B. output

Check P.C.B.

Replace the P.C.B.

E 14 Block in the ow probe control circuit

Check delivery probe/P.C.B.

Replace the P.C.B.

E 18 System ow temperature too high (over 95°C) Check the circulation of water in the system

E 19 System return temperature too high (over 87°C) Check the circulation of water in the system

E 25 Increase of the system ow temperature too quick

Check the circulation of water in the system

Check main exchanger

E 30 Temperature dierence between system ow and return too great Check the circulation of water in the system

E 31 System ow probe anomaly (short circuit) Replace system ow probe

E 32 System return probe anomaly (short circuit) Replace system return probe

E 36 System ow probe anomaly (open) Replace system ow probe

E 37 System return probe anomaly (open) Replace system return probe

E 114 Cascade address not valid

Check address set on the board (See cascade and zone

regulator assistance board)

FUSE 24 Vac missing Check the external transformer. Check P.C.B.

block conditions. To eliminate the block, press

the RESET button positioned on the boiler panel.

Loading...

Loading...