5 System Commissioning

-

171

-

The adjustment is based on the combination of “startup comfort adjustment without

a load cell” and “startup comfort adjustment with a load cell”.

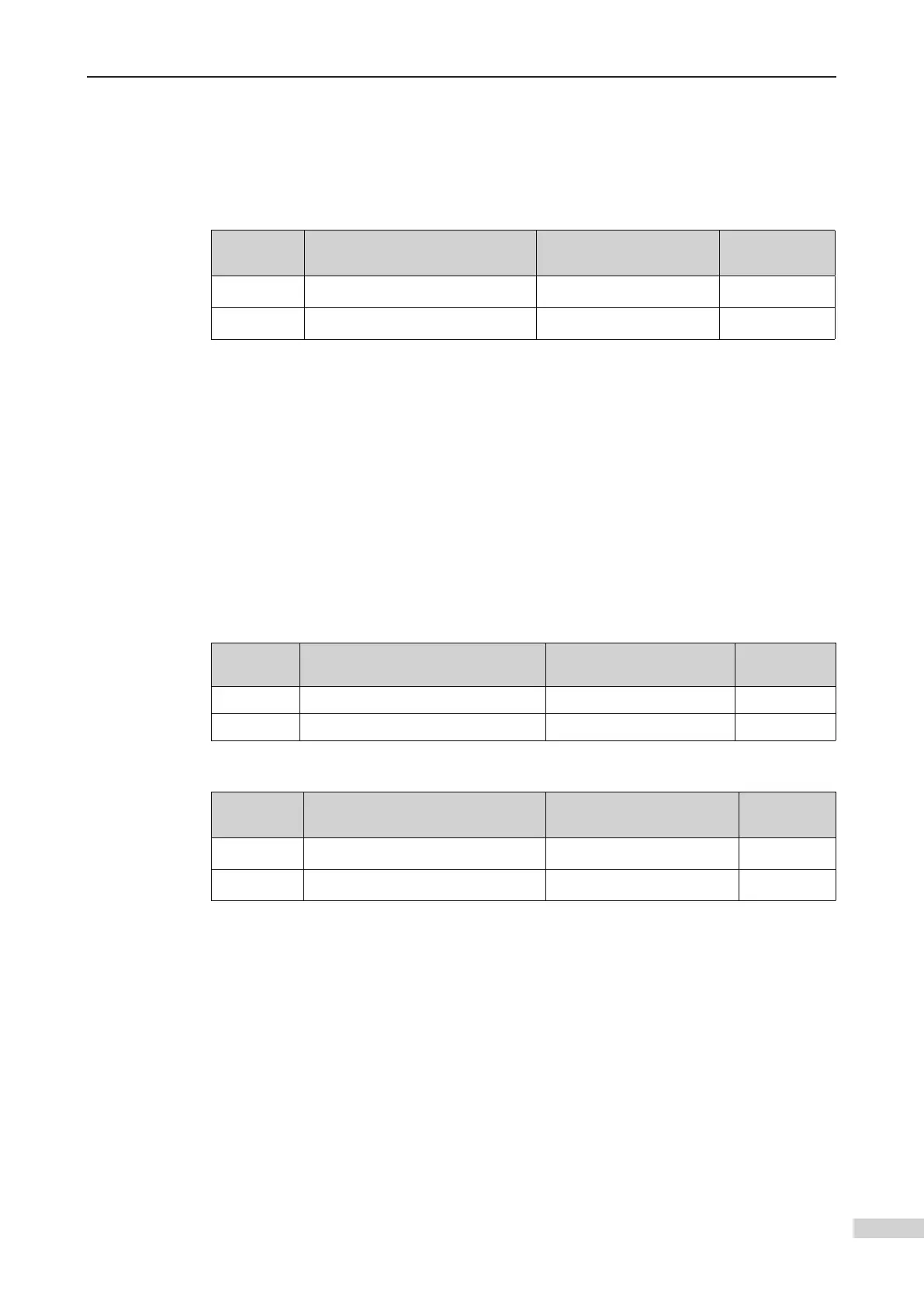

c) Handling of rollback at elevator startup and stop

The parameter setting related to rollback at elevator startup and stop is described in

the following table.

Function

Code

Name Setting Range Default

F3-19 Brake release delay 0.000 to 2.000s 0.600s

F8-11 Brake release delay 0.200 to 1.500s 0.600s

sends the brake release command to the moment when the brake is completely

released, during which the system retains the zero-speed torque current output. If

there is obvious rollback at elevator startup, increase F3-19 properly.

The system retains the zero-speed torque current output within the time set in F8-11

from the moment when the system sends the brake apply command; this is to prevent

rollback. If there is obvious rollback at elevator startup, increase F8-11 properly.

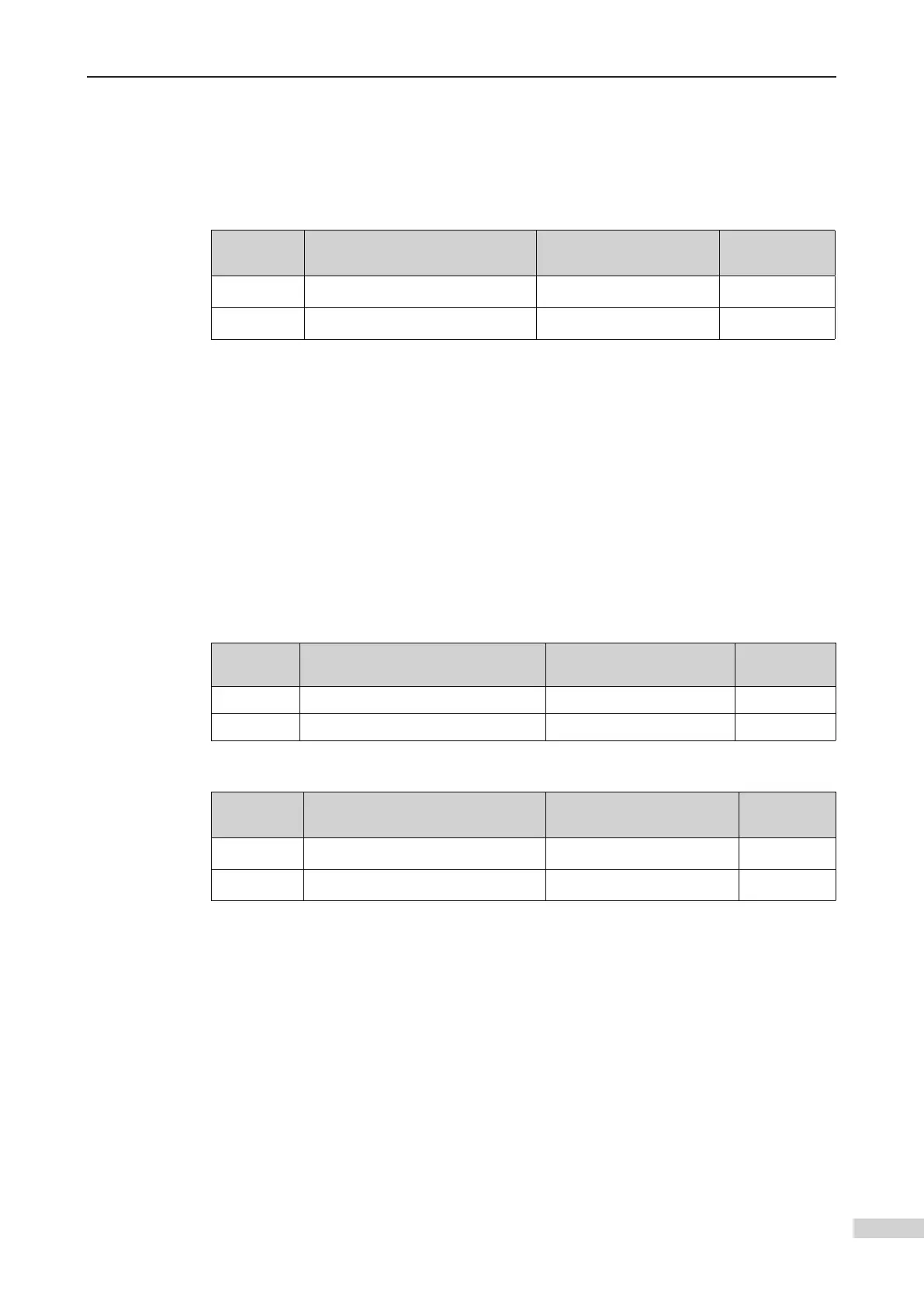

d) Handling of current noise at motor startup and stop

During elevator startup or stop, certain motors may generate noise when the current

is applied before the brake is released or the current is removed after the brake is

applied. To reduce motor noise, increase F2-16 or F2-17 properly.

Function

Code

Name Setting Range Default

F2-16 Torque acceleration time 1 to 500 1

F2-17 Torque deceleration time 1 to 3000 350

e

)

Adjustment at large mechanical static friction

Function

Code

Name Setting Range Default

F3-00 Startup speed 0.000m/s

F3-01 Startup holding time 0.000 to 5.000s 0.000s

Startup timing sequence for eliminating static friction

Loading...

Loading...