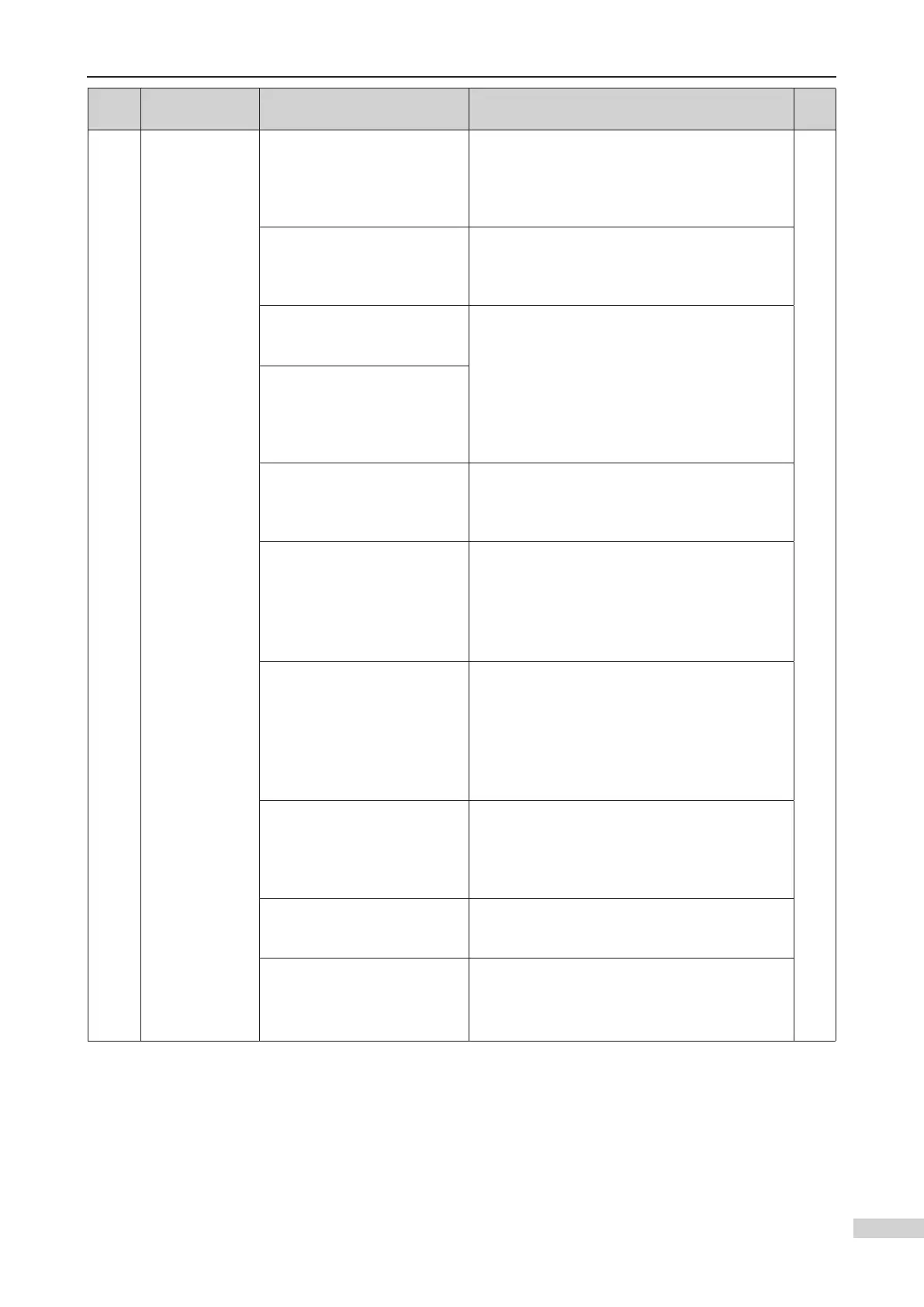

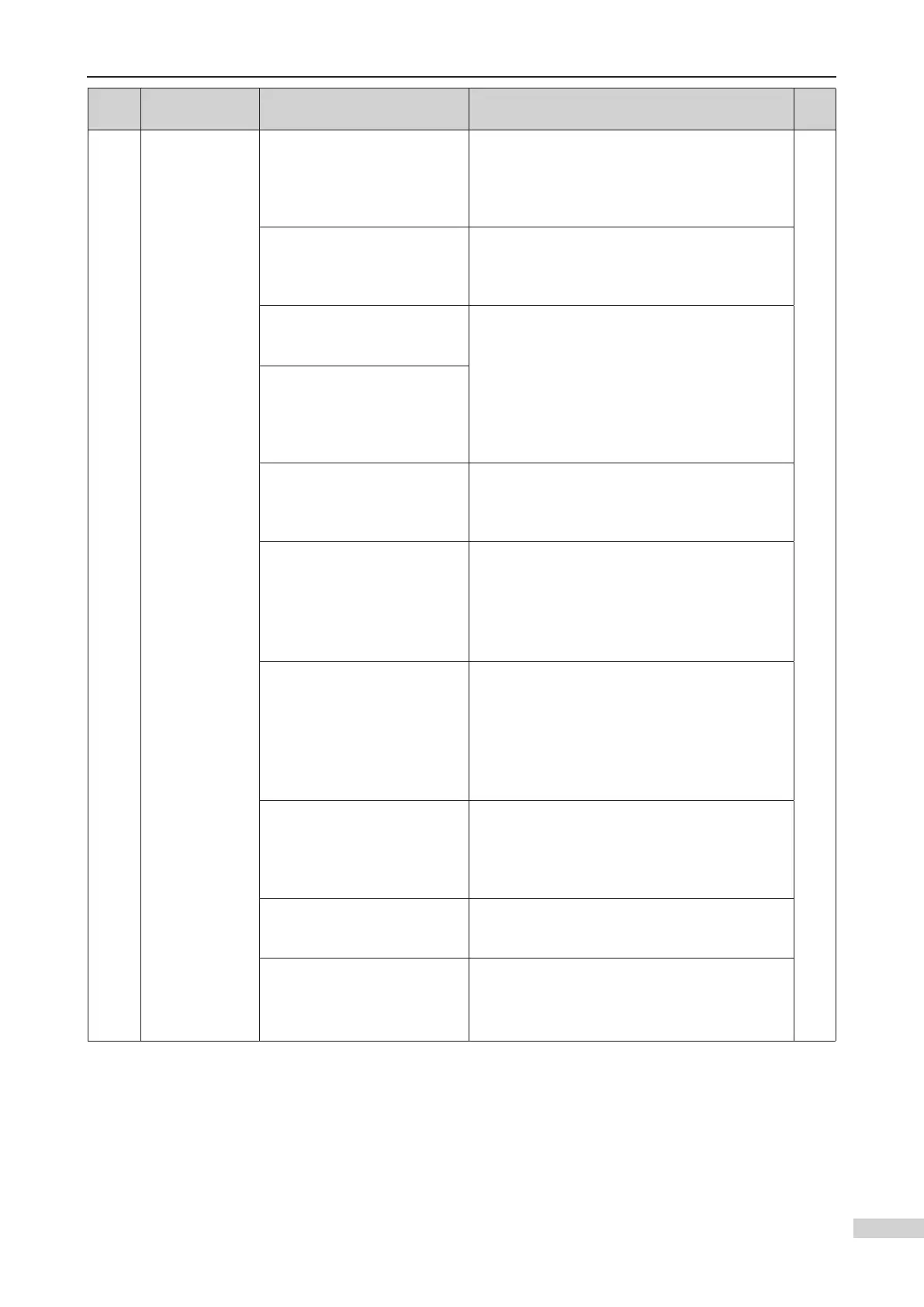

7 Troubleshooting

-

277

-

Fault

Code

Name Possible Causes Solution Level

Err35

Shaft auto-

tuning

data abnormal

Subcode 101: When shaft

auto-tuning is started, the

elevator is not at the bottom

switch is invalid,

◆

Check that the down slow-down switch is

4C

Subcode 102: The system is

not in the inspection state

(inspection switch not turned

on)

◆

when shaft auto-tuning is performed.

Subcode 103: It is judged upon

power-on that shaft auto-

tuning is not performed.

◆

Perform shaft auto-tuning again.

Subcodes 104, 113, 114: In

distance control mode, it is

judged at running startup

that shaft auto-tuning is not

performed.

Subcode 105: The elevator

running direction and the

pulse change are inconsistent.

◆

Check whether the elevator running direc-

tion is consistent with the pulse change in

F4-03: F4-03 increases in up direction and

decreases in down direction.

Subcodes 106, 107, 109: The

plate pulse length sensed at

up/down leveling is abnormal.

◆

Check that NO/NC state of the leveling

switch is set correctly.

◆

Check whether the leveling plates are in-

serted properly and whether there is strong

power interference if the leveling switch

signal blinks.

Subcodes 108, 110: No leveling

signal is received within 45s

continuous running.

◆

Check whether wiring of the leveling switch

is correct.

◆

large, causing running time-out. Increase

the speed set in F3-11 and perform shaft

auto-tuning again to ensure that learning

Subcodes 111, 115: The stored

cm.

◆

distance is normal, check installation of the

switch and its wiring.

auto-tuning is completed is

◆

set or the leveling plate is missing.

Subcode 116: The up and

down leveling signals are in

wrong sequence.

◆

Check whether the up and down leveling

wiring is correct.

◆

Check whether the up and down leveling

gaps are proper.

Loading...

Loading...