Reference Thermal Solution

29 Thermal and Mechanical Design Guidelines

4.4 Environmental Reliability Requirements

The environmental reliability requirements for the reference thermal solution are

shown in

Table 5 and Table 6. These should be considered as general guidelines.

Validation test plans should be defined by the user based on anticipated use

conditions and resulting reliability requirements.

The ATX testing will be performed with the sample board mounted on a test fixture

and includes a processor heatsink with a mass of 550g. The test profiles are

unpackaged board level limits.

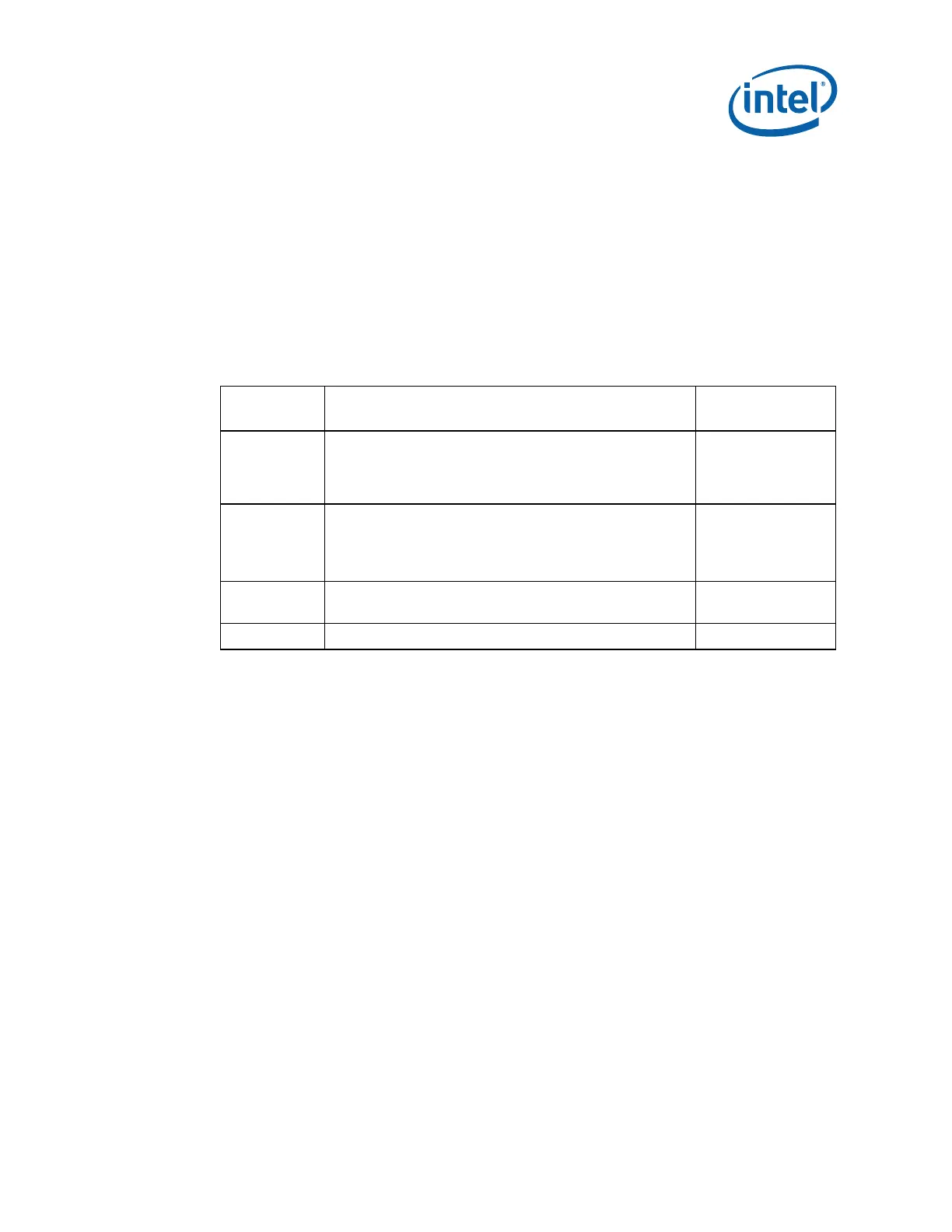

Table 5. ATX Reference Thermal Solution Environmental Reliability Requirements

(Board Level)

Test

1

Requirement Pass/Fail

Criteria

2

Mechanical

Shock

• 3 drops for + and - directions in each of 3

perpendicular axes (i.e., total 18 drops).

• Profile: 50 G, Trapezoidal waveform, 4.3 m/s

[170 in/s] minimum velocity change

Visual\Electrical

Check

Random

Vibration

• Duration: 10 min/axis, 3 axes

• Frequency Range: 0.01 g2/Hz @ 5Hz ramping to

0.02 g2/Hz @20 Hz, 0.02 g2/Hz @ 20 Hz to 500 Hz

• Power Spectral Density (PSD) Profile: 3.13 g RMS

Visual/Electrical

Check

Thermal

Cycling

• Non-Operating, -40 °C to +70 °C Thermal

Performance

Humidity • 85 % relative humidity / 55 °C Visual Check

NOTES:

1. The above tests should be performed on a sample size of at least 12 assemblies from 3

different lots of material.

2. Additional Pass/Fail Criteria may be added at the discretion of the user.

The current plan for BTX reference solution testing is to mount the sample board

mounted in a representative BTX chassis with a thermal module assembly having a

mass of 900g. The test profiles are unpackaged system level limits.

Loading...

Loading...