Reference Thermal Solution

27 Thermal and Mechanical Design Guidelines

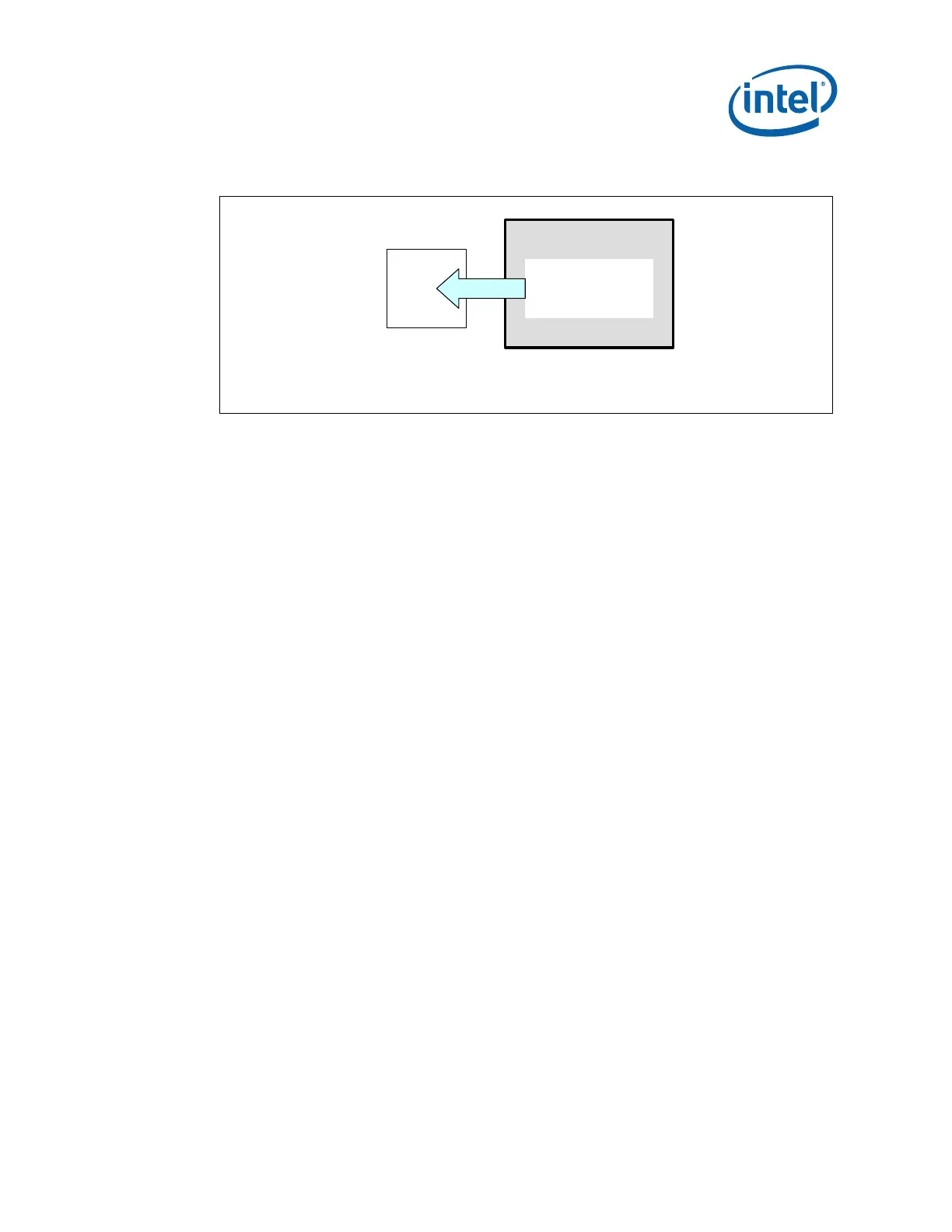

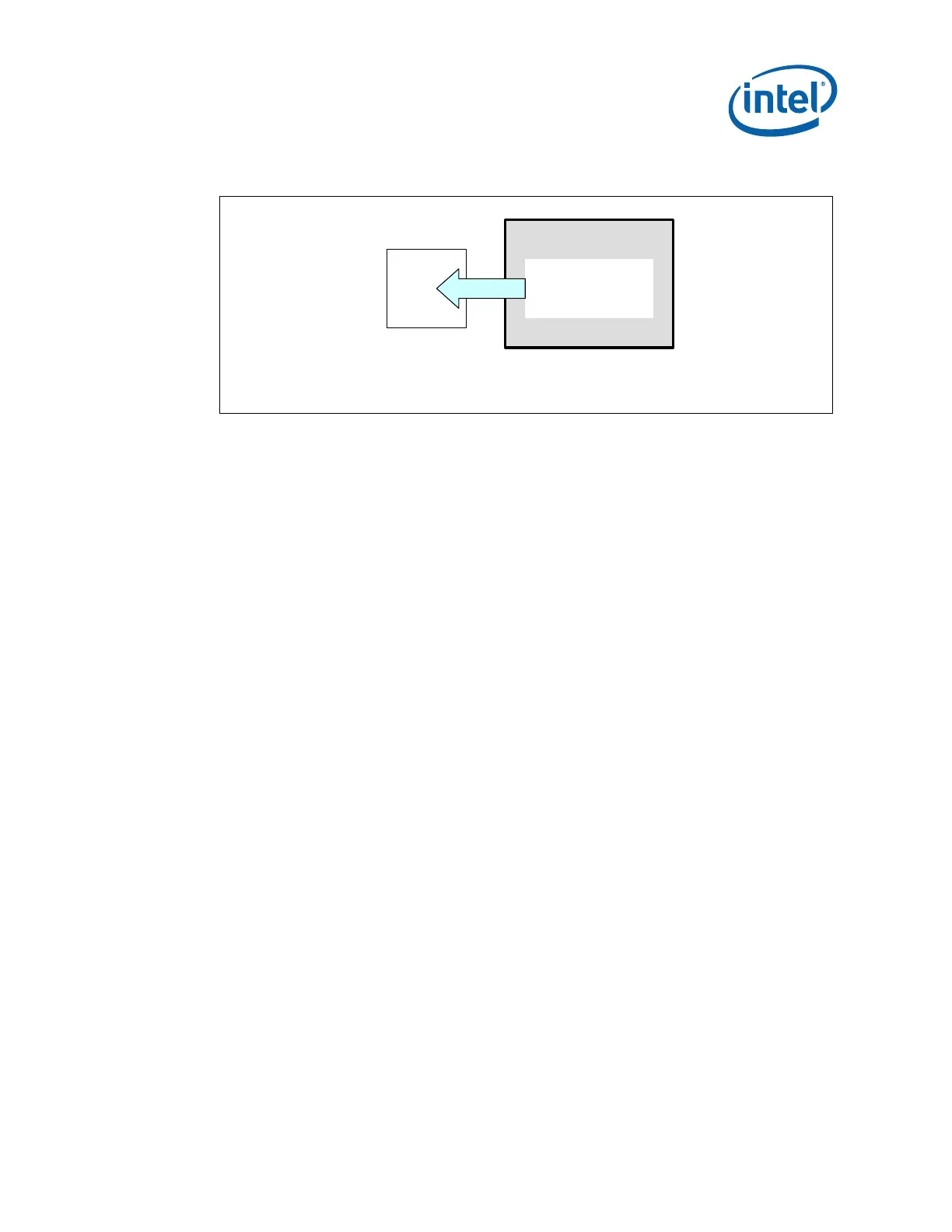

Figure 11. Processor Heatsink Orientation to Provide Airflow to (G)MCH Heatsink on a

Balanced Technology Extended (BTX) Platform

BTX Thermal

Module Assembly

over processor

Airflow Direction

GMCH

Top View

4.2 Reference Design Mechanical Envelope

The motherboard component keep-out restrictions for the (G)MCH on an ATX platform

are included in

Appendix B, Figure 15. The motherboard component keep-out

restrictions for the (G)MCH on a BTX platform are included in Appendix B, Figure 16.

4.3 Thermal Solution Assembly

The reference thermal solution for the (G)MCH for an ATX chassis is shown in

Figure 12 and is an aluminum extruded heatsink that uses two ramp retainers, a wire

preload clip, and four motherboard anchors. Refer to

Appendix B for the mechanical

drawings. The heatsink is attached to the motherboard by assembling the anchors into

the board, placing the heatsink, with the wire preload clip over the (G)MCH and

anchors at each of the corners, and securing the plastic ramp retainers through the

anchor loops before snapping each retainer into the fin gap. Leave the wire preload

clip loose in the extrusion during the wave solder process. The assembly is then sent

through the wave process. Post wave, the wire preload clip is snapped into place on

the hooks located on each of the ramp retainers. The clip provides the mechanical

preload to the package. This mechanical preload is necessary to provide both

sufficient pressure to minimize thermal contact resistance and improvement for solder

ball joint reliability. The mechanical stiffness and orientation of the extruded heat sink

also provides protection to reduce solder ball reliability risk. A thermal interface

material (Honeywell PCM45F) is pre-applied to the heatsink bottom over an area

which contacts the package die.

The design concept for the (G)MCH in a BTX chassis is shown in

Figure 13. The

heatsink is aluminum extruded and utilizes a Z-clip for attach. The clip is secured to

the system motherboard via two solder down anchors around the (G)MCH. The clip

helps to provide a mechanical preload to the package via the heatsink. A thermal

interface material (Honeywell PCM45F) will be pre-applied to the heatsink bottom over

an area in contact with the package die.

Note: To minimize solder ball joint reliability risk, the BTX Z-clip heatsink is intended to be

used with the Support Retention Mechanism (SRM) described in the Balanced

Technology Extended (BTX) Interface Specification. For additional information on

designing the BTX chassis to minimize solder ball joint reliability, refer to the Balanced

Technology Extended (BTX) Chassis Design Guide.

Loading...

Loading...