7

Version 1.1 (11/2011) en

Original language

9006 Hybrid Control for RollerDrive

Product information

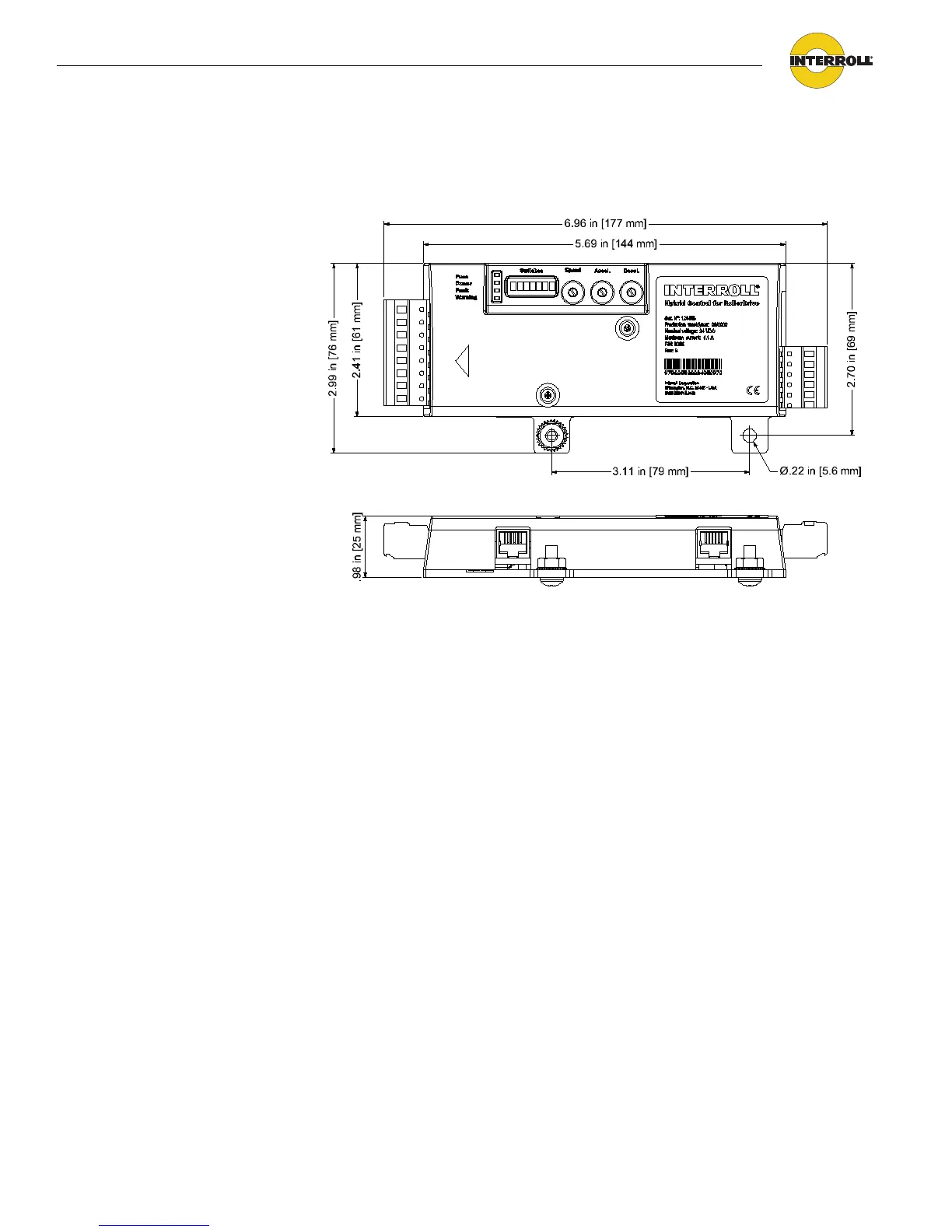

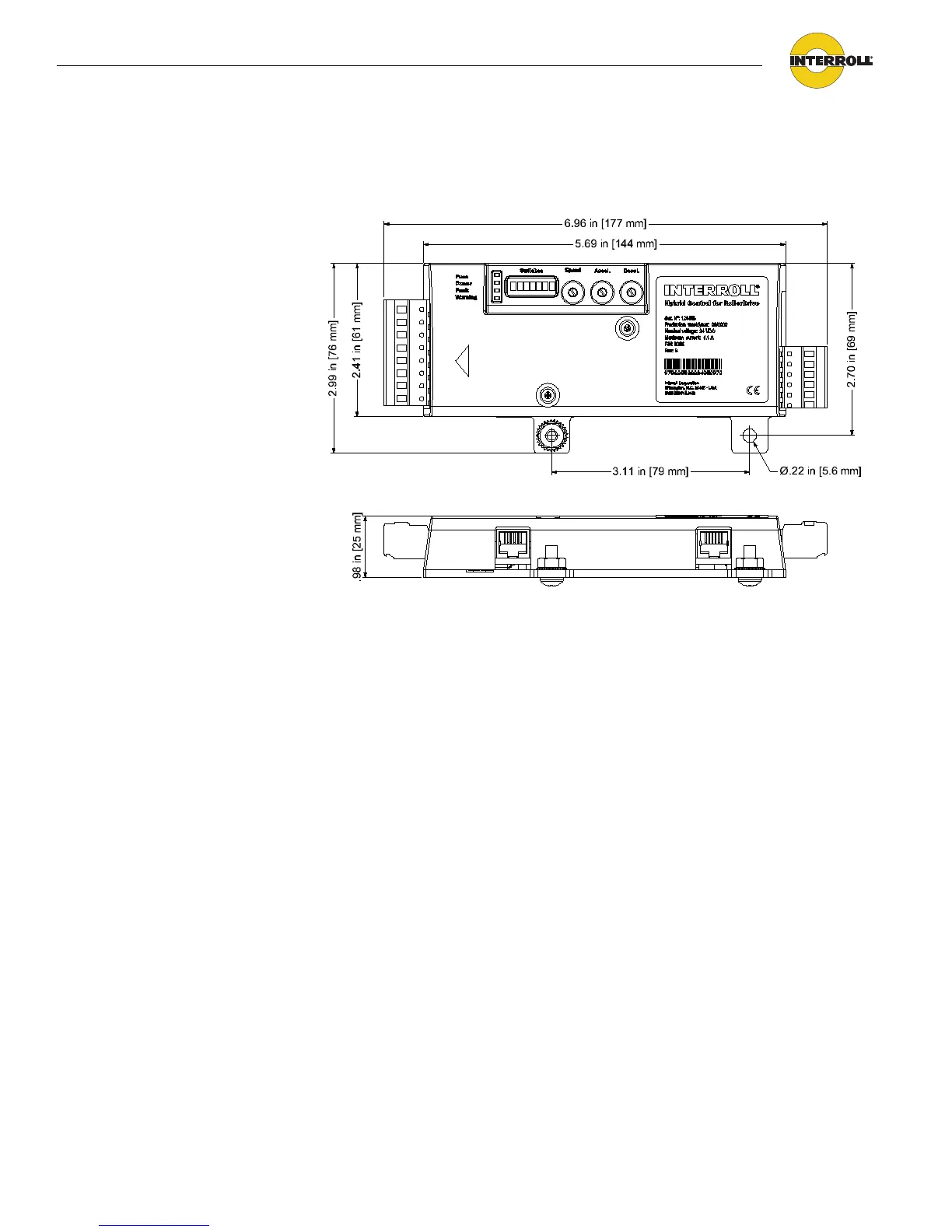

Dimensions

Mounting hardware The following mounting hardware is supplied:

• 2x button head screw 10-32 UNF x 0.5"

• 2x nut with captive star washer 10-32 UNF

ZPA technology

ZPA is short for zero pressure accumulation. The 9006 provides true

zero pressure accumulation and other control options to a conveyor system.

Each 9006 controls a RollerDrive unit, which in turn drives idler rollers

using O-rings or other belts. The 9006, the RollerDrive, and the idler

rollers (with associated sensors and switches) are assembled into a short

conveyor section – a zone.

Zero pressure accumulation occurs as zones hold packages until the next

downstream zone clears its sensor. When accumulation occurs, a low signal is

passed upstream until each consecutive zone is occupied. Packages never push

each other, and no line pressure occurs.

A logic-controlled, zero pressure conveyor is created when a number of zones

are connected together and a simple six-wire phone cable links each

9006 electronically. The RollerDrives only operate when a package is

detected by a photoeye. If the downstream zone is empty, the package moves

forward.

Loading...

Loading...