OptidriveODP‐2UserGuideRevisions1.30

42

www.invertekdrives.com

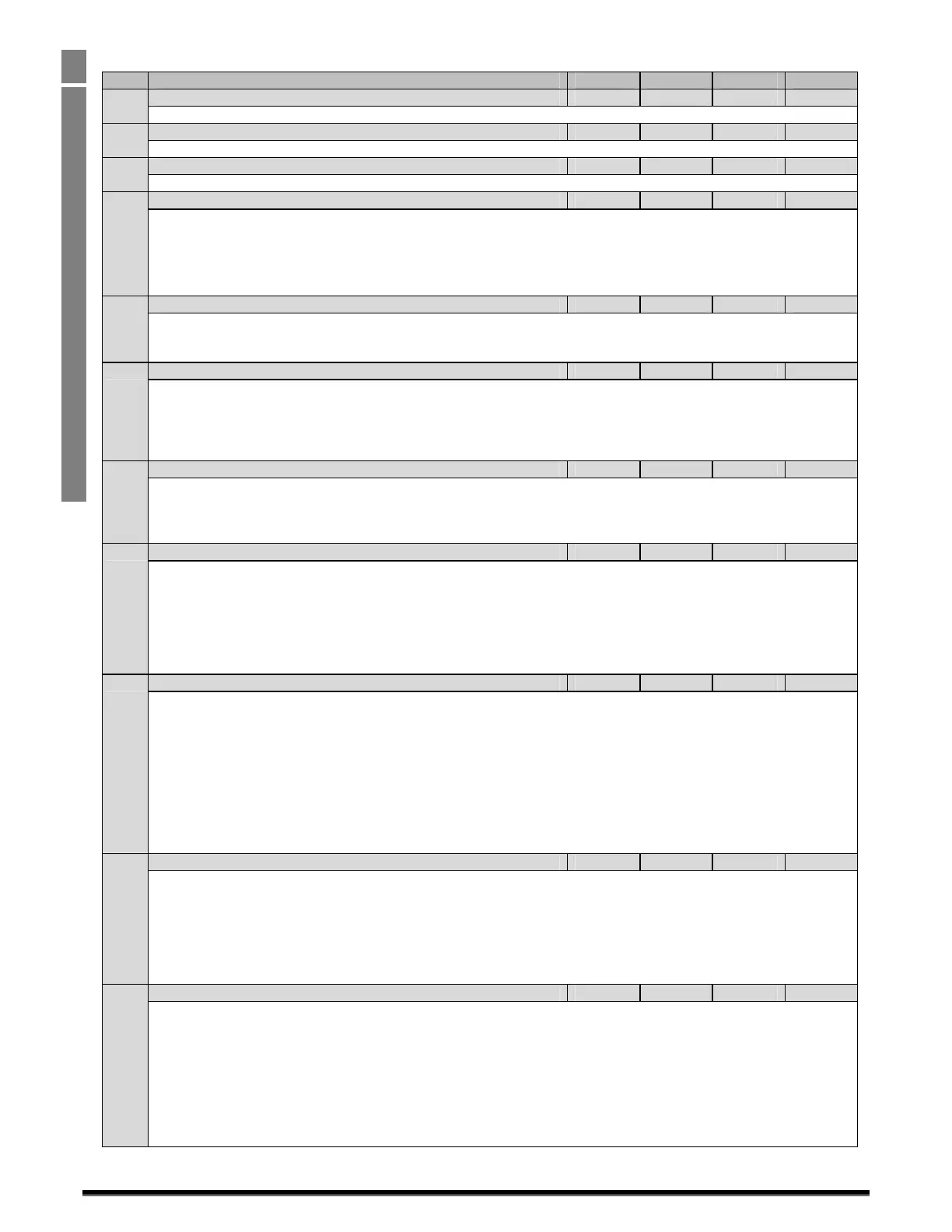

8ExtendedParameters

8.4. ParameterGroup5–CommunicationParameters

Par. Name Minimum Maximum Default Units

P5‐01 DriveFieldbusAddress 0 63 1 ‐

SetsthefieldbusaddressfortheOptidrive

P5‐02 CANOpenBaudRate 125 1000 500 kbps

SetsthebaudratewhenCANOpencommunicationsareused

P5‐03 ModbusRTUBaudRate 9.6 115.2 115.2 kbps

SetsthebaudratewhenModbusRTUcommunicationsareused

P5‐04 ModbusDataFormat ‐ ‐ ‐ ‐

SetstheexpectedModbustelegramdataformatasfollows

n-1:NoParity,1stopbit

n-2:Noparity,2stopbits

0-1:Oddparity,1stopbit

E-1:Evenparity,1stopbit

P5‐05 CommunicationsLossTimeout 0.0 5.0 2.0 Seconds

Setsthewatchdogtimeperiodforthecommunicationschannel.IfavalidtelegramisnotreceivedbytheOptidrivewithinthis

timeperiod,thedrivewillassumealossofcommunicationshasoccurredandreactasselectedbelow.Settingtozerodisables

thefunction.

P5‐06 CommunicationsLossAction 0 3 0 ‐

Controlsthebehaviourofthedrivefollowingalossofcommunicationsasdeterminedbytheaboveparametersetting.

0:Trip&CoastToStop

1:RamptoStopThenTrip

2:RamptoStopOnly(NoTrip)

3:RunatPresetSpeed8

P5‐07 FieldbusRampControl 0 1 0 ‐

SelectswhethertheaccelerationanddecelerationrampsarecontroldirectlyviatheFieldbus,orbyinternaldriveparametersP1‐

03andP1‐04.

0:Disabled.Rampsarecontrolfrominternaldriveparameters

1:Enabled.RampsarecontrolleddirectlybytheFieldbus

P5‐08 FieldbusProcessDataOutputWord4Select 0 4 0 ‐

Whenusinganoptionalfieldbusinterface,thisparameterconfigurestheparametersourceforthe4

t

processdataword

transferredfromthedrivetothenetworkmasterduringcycliccommunications

0:OutputTorque–0to2000=0to200.0%

1:OutputPower–OutputpowerinkWtotwodecimalplaces,e.g.400=4.00kW

2:DigitalInputStatus–Bit0in

dicatesdigitalinput1status,bit1indicatesdigitalinput2statusetc.

3:AnalogInput2SignalLevel–0to1000=0to100.0%

4:DriveHeatsinkTemperature–0to100=0to100°C

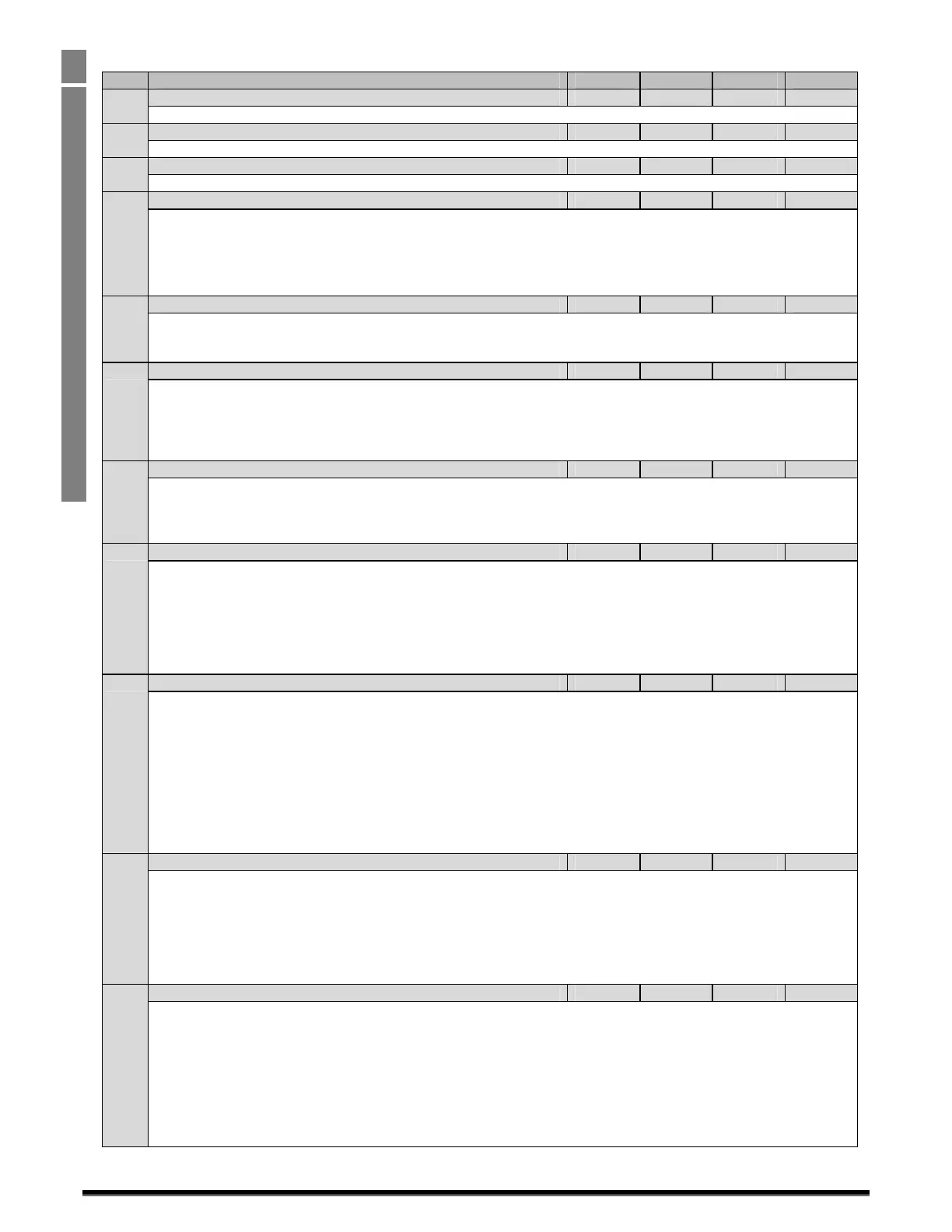

P5‐12 FieldbusProcessDataOutputWord3Select 0 7 0 ‐

Whenusinganoptionalfieldbusinterface,thisparameterconfigurestheparametersourceforthe3

r

processdataword

transferredfromthedrivetothenetworkmasterduringcycliccommunications

0:Motorcurrent–Outputcurrentto1decimalplace,e.g.100=10.0Amps

1:Power(x.xxkW)OutputpowerinkWtotwodecimalplaces,e.g.400=4.00kW

2:Digitalinputstatus–Bit0indi

catesdigitalinput1status,bit1indicatesdigitalinput2statusetc.

3:AnalogInpu t2SignalLevel‐0to1000=0to100.0%

4:DriveHeatsinkTemperature–0to100=0to100°C

5:Userregister1–UserDefinedRegister1Value

6:Us

erregister2–UserDefinedRegister1Value

7:P0‐80value–UserSelecteddatavalue.

P5‐13 FieldbusProcessDataInputWord4Select 0 1 0 ‐

Whenusinganoptionalfieldbusinterface,thisparameterconfiguresdestinationforthe4

t

processdatawordreceivedbythe

drivefromthenetworkmasterduringcycliccommunications

0:FieldbusRampControl–Thisoptionmustbeselectedifthedriveaccelerationanddecelerationrampsaretobecontrolled

fromthefieldbus.P5‐07mustalsobesetto1toenablethisfunction.

1:Us

erregister4–ThevaluereceivedbythedriveinPDI4istransferredtoUserRegister4.Thisoptionallowsthefunctionof

theprocessdatawordtobedefinedinParameterGroup9.Inthiscase,UserRegister4shouldnotbewrittentowithinanyPLC

fu

nctioncode,althoughthevaluecanberead.

P5‐14 FieldbusProcessDataInputWord3Select 0 2 0 ‐

Whenusinganoptionalfieldbusinterface,thisparameterconfiguresdestinationforthe3

r

processdatawordreceivedbythe

drivefromthenetworkmasterduringcycliccommunications

0:Torquelimit/reference–Thisoptionmustbeselectedifthedriveoutputtorquelimit/setpointistobecontrolledfromthe

fieldbus.ThisalsorequiressettingP4‐06=3.

1:UserPIDreferenceregister–Thisop

tionallowsthesetpointtothePIDcontrollertobereceivedfromtheFieldbus.Inorder

forthisoptiontobeused,P9‐38mustbesetto1,andthePIDUsersetpointmustnotbeutilisedwithinthePLCfunction.

2:Userregister3‐Thevaluere

ceivedbythedriveinPDI3istransferredtoUserRegister3.Thisoptionallowsthefunctionofthe

processdatawordtobedefinedinParameterGroup9.Inthiscase,UserRegister3shouldnotbewrittentowithinanyPLC

functioncode,althoughthevaluecanbere

ad.

Loading...

Loading...