OptidriveODP‐2UserGuideRevisions1.30

22

www.invertekdrives.com

4ElectricalInstallation

4.10. SafeTorqueOff

SafeTorqueOFFwillbereferredtoas“STO”throughtheremainderofthissection.

4.10.1. Responsibilities

Theoverallsystemdesignerisresponsiblefordefiningtherequirementsof the overall“SafetyControlSystem”withinwhichthedrivewillbe

incorporated; furthermore the system designer is responsible for ensuring that the complete system is risk assessed and that the “Safety

controlSystem”requirementshavebeenentirelymetandthatth

efunctionisfullyverified,thismustincludeconfirmationtestingofthe“STO”

functionbeforedrivecommissioning.

Thesystemdesignershalldeterminethepossiblerisksandhazardswithinthesystembycarryingout athoroughriskandhazardanalysis,the

outcomeof theanalysisshould providean estimateof thepossiblehazards,fu

rthermoredeterminetherisklevelsandidentify anyneedsfor

riskreduction.The“STO”functionshouldbeevaluatedtoensureitcansufficientlymeettherisklevelrequired.

4.10.2. WhatSTOProvides

Thepurposeofthe“STO“functionistoprovideamethodofpreventingthedrivefromcreatingtorqueinthemotorintheabsenceofthe“STO“

inputsignals(Terminal12withrespecttoTerminal13),thisallowsthedrivetobeincorporatedintoacompletesafetycontrolsystemwhere

“STO“re

quirementsneedtobefulfilled.

1

The“STO“functioncantypicallyeliminatetheneedforelectro‐mechanicalcontactorswithcross‐checkingauxiliarycontactsaspernormally

requiredtoprovidesafetyfunctions.

2

Thedrivehasthe“STO“Functionbuilt‐inasstandardandcomplieswiththedefinitionof“Safetorqueoff“asdefinedbyIEC61800‐5‐2:2007.

The“STO“Functionalsocorrespondstoanuncontrolledstopinaccordancewithcategory0(EmergencyOff),ofIEC60204‐1.Thismeansthat

themotorw

illcoasttoastopwhenthe“STO”functionisactivated,thismethodofstoppingshouldbeconfirmedasbeingacceptabletothe

systemthemotorisdriving.

The“STO“functionisrecognisedasafailsafemethodeveninthecasewherethe“STO“signalisabsentandasi

nglefaultwithinthedrivehas

occured,thedrivehasbeenproveninrespectofthisbymeetingthefollowingsafetystandards:

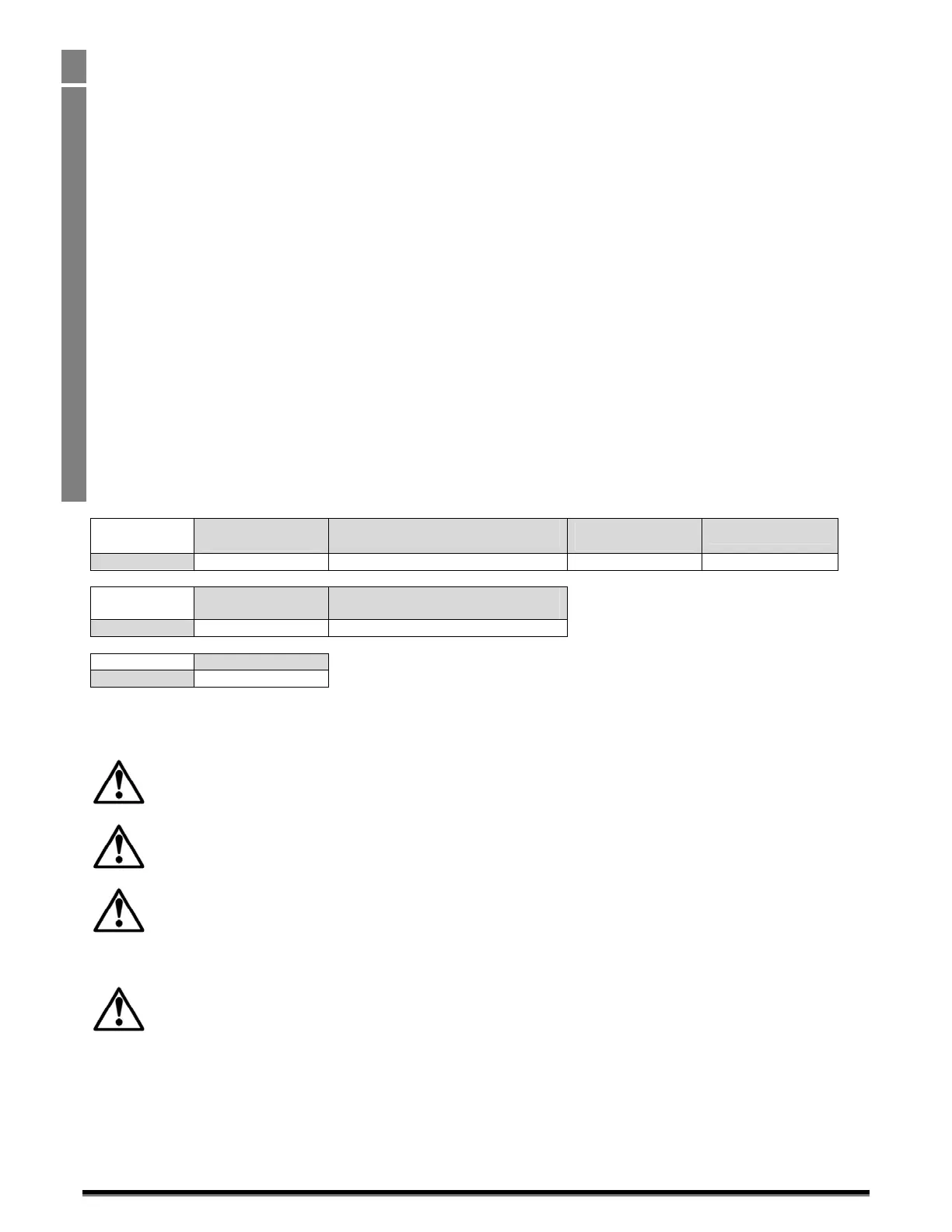

SIL

(SafetyIntegrityLev el)

PFH

D

(ProbabilityofdangerousFailuresperHour)

SFF

(Safefailurefraction%)

Lifetimeassumed

EN61800‐5‐2 2 1.23E‐091/h(0.12%ofSIL2) 50 20Yrs

PL

(Performancelevel)

CCF(%)

(CommonCauseFailure)

ENISO13849‐1 PLd 1

SILCL

EN62061 SILCL2

Note:ThevaluesacheivedabovemaybejepardisedifthedriveisinstalledoutsideoftheEnvironmentallimitsdetailedinsection10.1

“Environmental“.

4.10.3. WhatSTOdoesnotprovide

DisconnectandISOLATEthedrivebeforeattemptinganyworkonit.The“STO“functiondoesnotpreventhighvoltagesfrombeing

presentatthedrivepowerterminals.

1

Note : The “STO“ function does not prevent the drive from an unexpected re‐start. As soon as the “STO“inputs receive the

relevantsignalitispossible(subjecttoparametersettings)torestartautomatically,Basedonthis,thefunctionshouldnotbeused

forcarryingoutshort‐termnon‐electricalmachineryop

erations(suchascleaningormaintenancework).

2

Note:Insomeapplicationsadditionalmeasuresmayberequiredtofulfilthesystemssafetyfunctionneeds:the“STO“function

doesnotprovidemotorbraking.Inthecasewheremotorbrakingisrequiredatimedelaysafetyrelayand/oramechanicalbrake

arrangementorsimilarmethodshouldbeadopted,considerationshou

ldbemadeovertherequiredsafetyfunctionwhenbraking

as

thedrivebrakingcircuitalonecannotberelieduponasafailsafemethod.

Whenusingpermanentmagnetmotorsandintheunlikelyeventofamultipleoutputpowerdevicesfailingthenthemotorcould

effectivelyrotatethemotorshaf

tby180/pdegrees(Wherepdenotesnumberofmotorpolepairs).

Loading...

Loading...