Optidrive HVAC User Guide V2.00

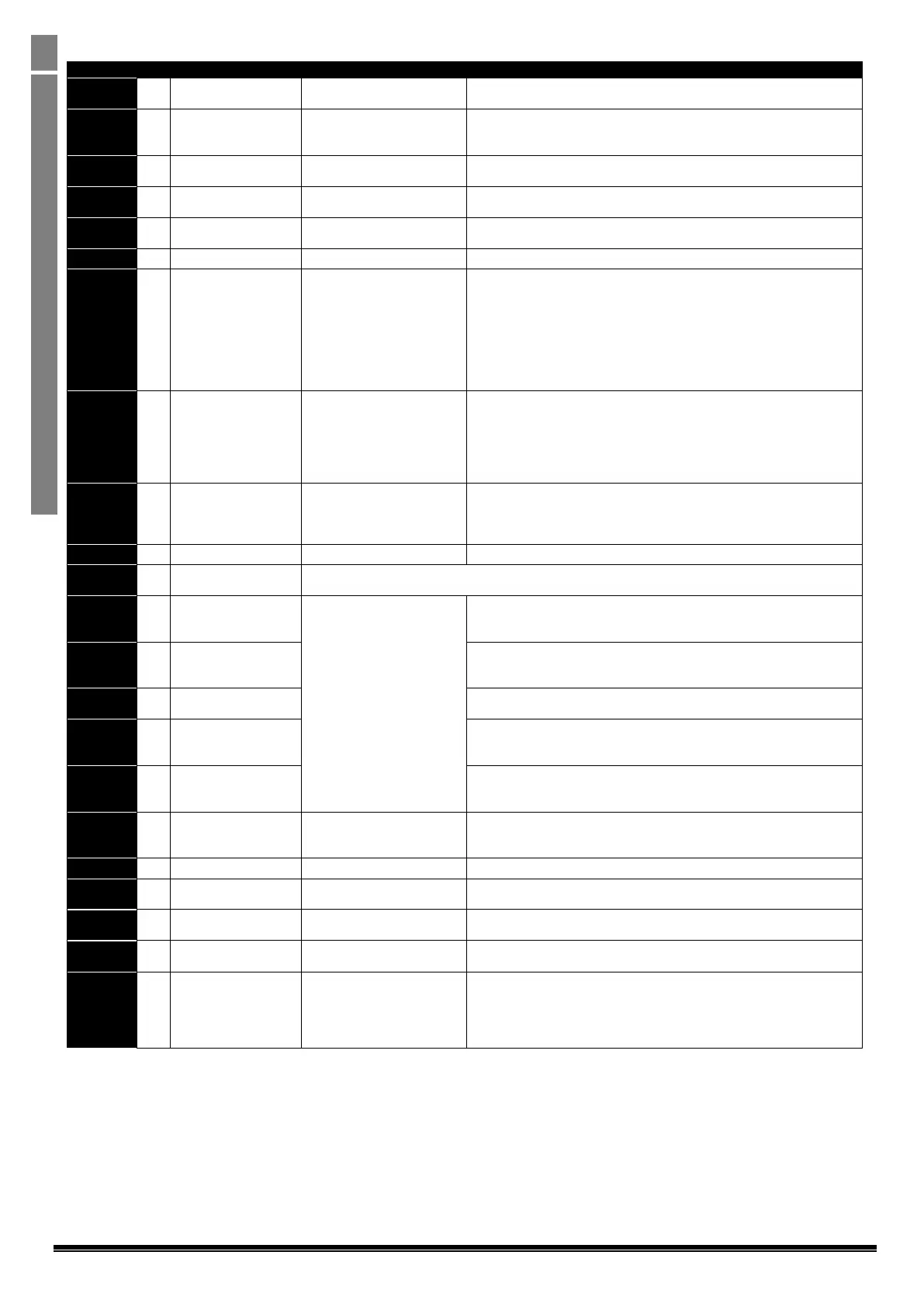

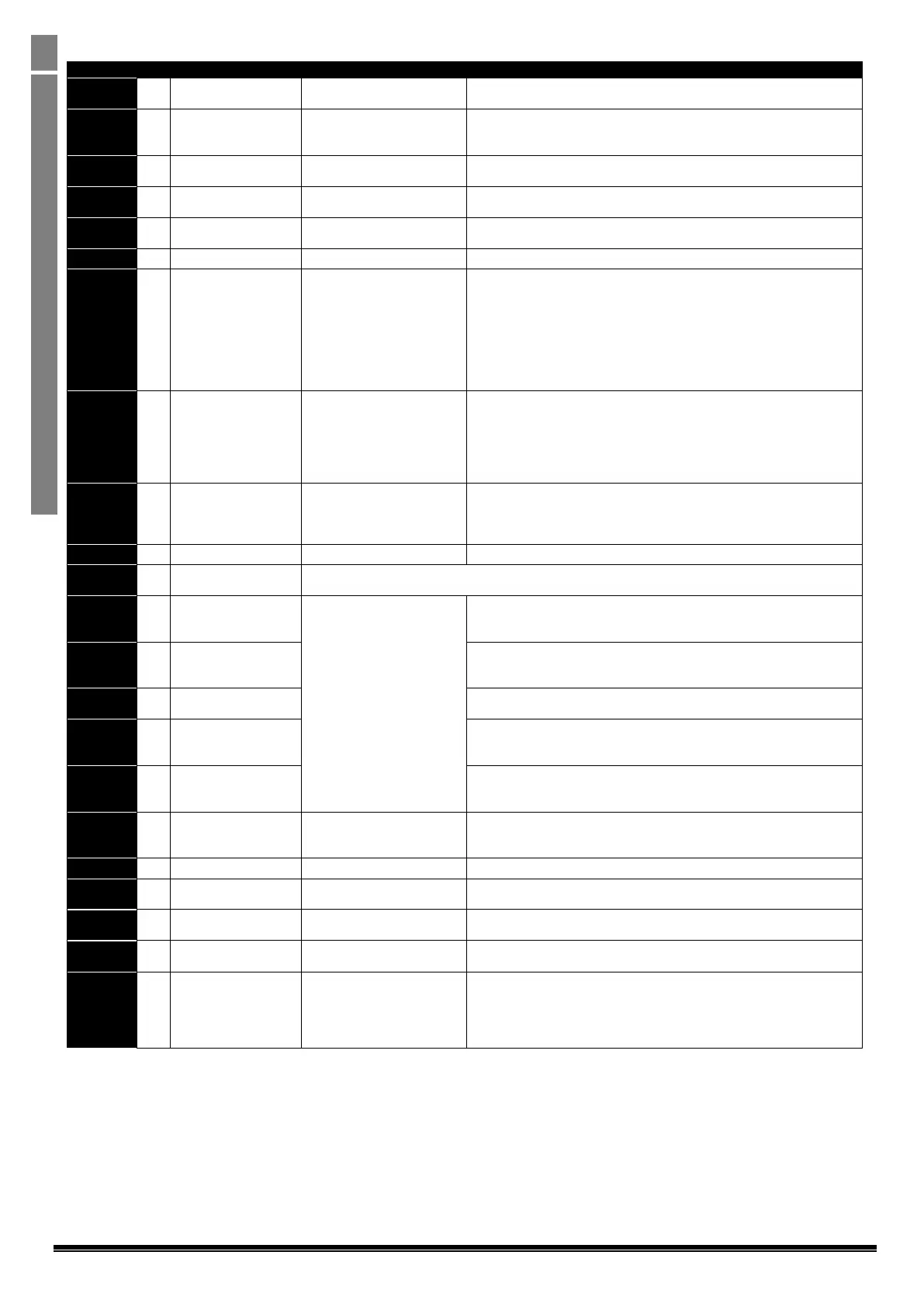

Parameters not saved, factory defaults are reloaded.

If problem reoccurs, refer to your IDL Authorised Distributor.

4-20mA signal out of

range

The reference signal on Analog Input 1 or 2 (Terminals 6 or 10) has dropped

below the minimum threshold of 3mA when signal format is set to 4-20mA.

Check the signal source and wiring to the Optidrive terminals.

Parameters not saved, factory defaults are reloaded.

If problem reoccurs, refer to your IDL Authorised Distributor.

User Parameter default has been loaded. Press the Stop key. Three button

default – see section 5.9

Motor PTC Over Temperature

The connected motor PTC device has caused the drive to trip (analog input 2

configured for PTC device).

Check and if necessary, replace the drive internal cooling fan

Ambient Temperature too

High

The measured temperature around the drive is above the operating limit.

Ensure the drive internal cooling fan is operating

Ensure that the required space around the drive as shown in sections 3.8

thru 3.10 has been observed, and that the cooling airflow path to and from

the drive is not restricted

Increase the cooling airflow to the drive

Reduce the effective switching frequency setting in parameter P2-24

Reduce the load on the motor / drive

Current Monitoring Function has detected current levels above the normal

operating condition for the application.

Check mechanical load has not changed and that the load is not jammed or

stalling.

For pump application check for potential pump blockage

For fan applications check airstream to and from the fan is not restricted

Current Monitoring Function has detected current levels below the normal

operating condition for the application.

Check for mechanical breakages causing loss of load (e.g. belt break).

Check motor has not become disconnected from the drive.

Drive output fault, refer to your IDL Authorised Distributor

Internal STO circuit

Error

Refer to your Invertek Sales Partner

Measured motor stator resistance varies between phases. Ensure the motor

is correctly connected and free from faults. Check the windings for correct

resistance and balance.

Measured motor stator resistance is too large. Ensure the motor is correctly

connected and free from faults. Check that the power rating corresponds to

the power rating of the connected drive.

Measured motor inductance is too low. Ensure the motor is correctly

connected and free from faults.

Measured motor inductance is too large. Ensure the motor is correctly

connected and free from faults. Check that the power rating corresponds to

the power rating of the connected drive.

Measured motor parameters are not convergent. Ensure the motor is

correctly connected and free from faults. Check that the power rating

corresponds to the power rating of the connected drive.

Low Pressure Detected by Pipe

Fill Function

Check the pump system for leaks for burst pipes.

Check the Pipe fill function has been commissioned correctly (P3-16 & P3-

17)

Output (Motor) Phase Loss

One of the motor output phases is not connected to the drive.

Modbus communication error

detected

Fitted communication Module

Fault

Internal communication to the inserted Communications Option Module has

been lost. Check the module is correctly inserted

Internal communication to the inserted I/O Option Module has been lost.

Check the module is correctly inserted

A valid BACnet telegram has not been received within the watchdog time

limit set in P5-05

Check the network master / PLC is still operating

Check the connection cables

Increase the value of P5-05 to a suitable level

82-HVMAN-IN_V2.00

Loading...

Loading...