SECTION 3 - INDUSTRIAL APPLICATION 71

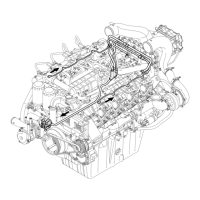

VECTOR 8 ENGINES

Print P2D32V001E Base - April 2006

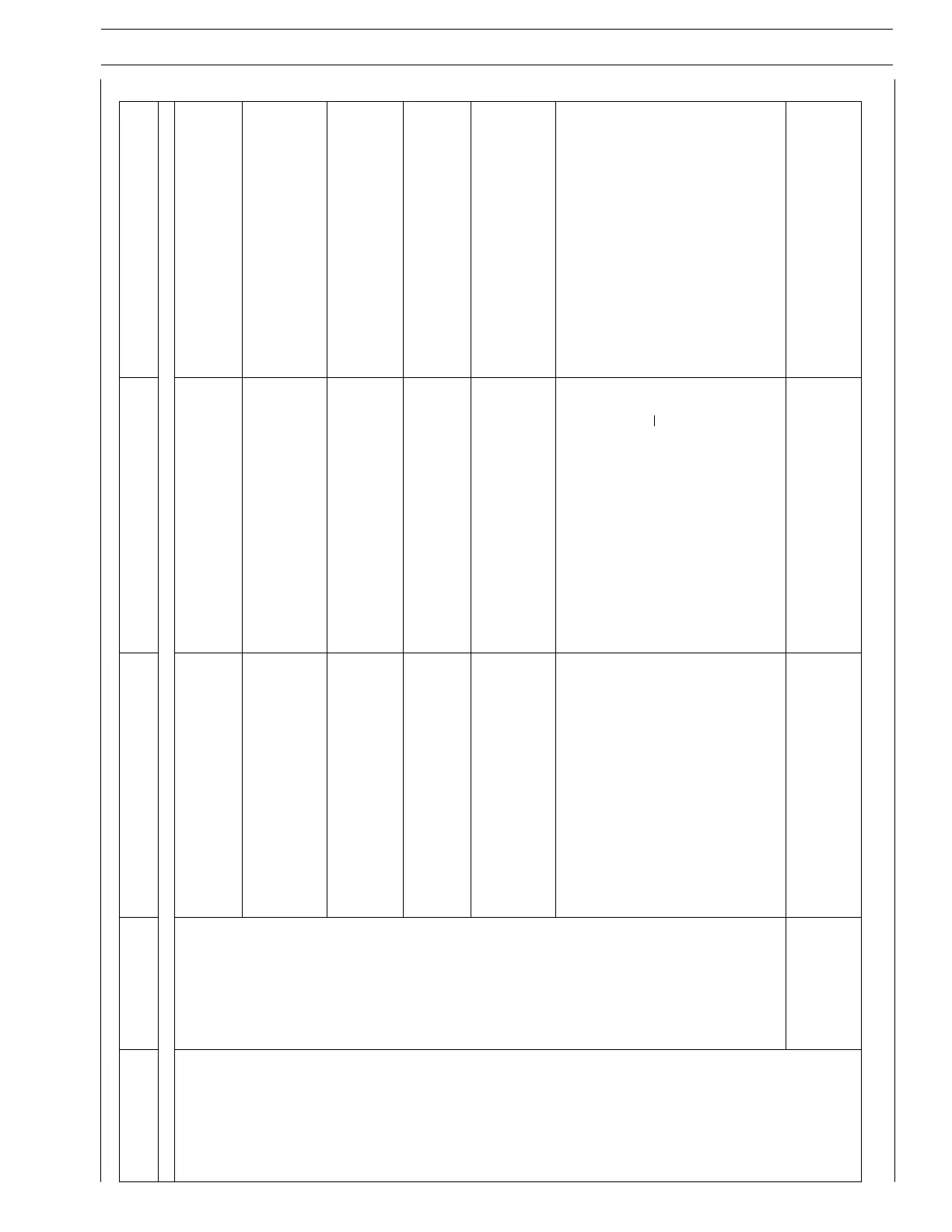

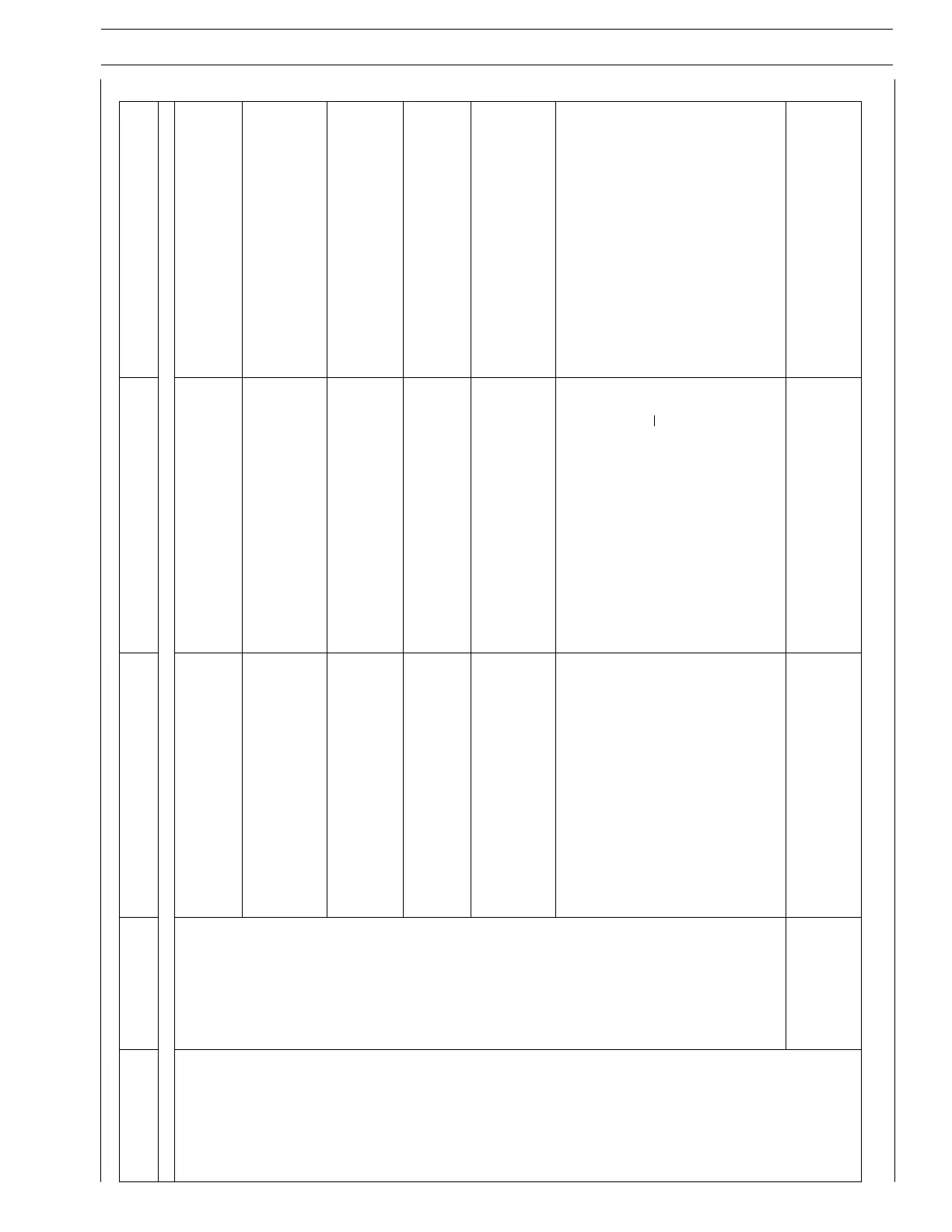

Symptom

Visible

trouble

Possible cause Repair Notes

Attributable to electrical malfunctioning:

Starting motor cables connected

improperly or not connected at all

Connect electrical cables properly

Starter motor defective. Replace starter motor.

(Changing the motor must be the last activity

to do if all the preceding checks have proved

negative).

The relay for starter motor shorted or

circuit open.

Check cable integrity before requesting relay

replacement

In this case the diagnosis is available in the

unit

Unit diagnosis inhibited at startup

Check diagnosis codes present in order to

verify the cause.

The engine will not

start.

No sign of starting.

Trouble in the ADEM III electronic control

unit.

(Short circuit)

Check unit cabling integrity before replacing

it

No enabled diagnosis is available (the unit is

damaged)

Crankshaft sensor: no signal or signal not

plausible.

Check the sensor is clean and correctly

secured.

Check the phonic wheel is clean and integral.

Check the integrity of the sensor (R ~

920

Ω).

If the sensor is integral, check the wiring

between the sensor connector (wiring side)

pin 1 and the XJ2 EDC connector pin 49,

between the sensor connector (wiring side)

pin 2 and the XJ2 EDC connector pin 48.

The engine fails to start because after a few

turns the control unit turns off the starter

motor.

This check cannot be made with the motor

fitted: it i s necessary to remove the flywheel

housing.

Total absence of

pressure in the rail

Pressure sensor damaged

Check the trouble level of sensor and wiring

and change the defective components.

Loading...

Loading...