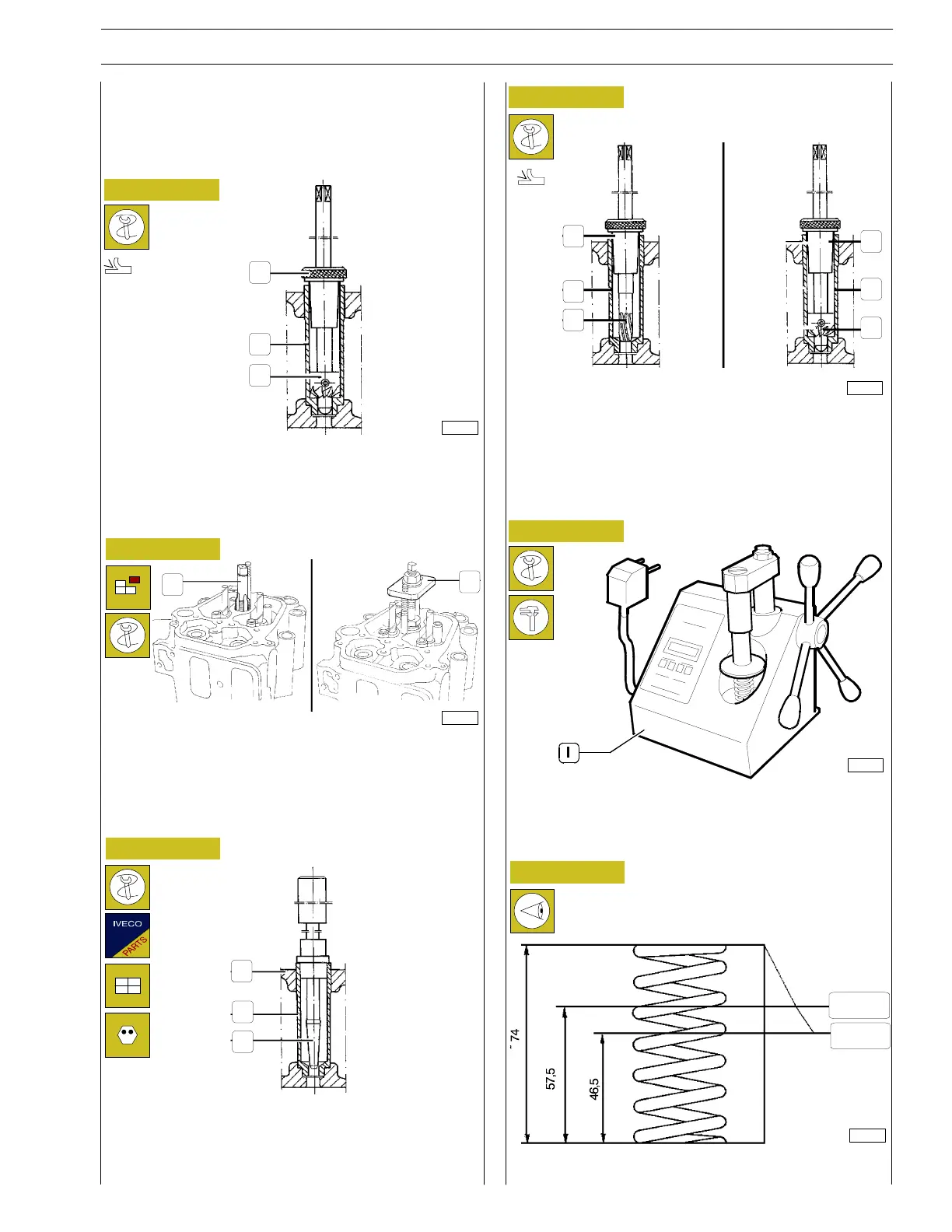

Figure 89

Figure 90

- Fit the new case (2) in the cylinder head (1) and

cold—head its bottom seat, on the cylinder head, with the

cold—heading tool 99365063 (3).

Figure 91

Figure 92

- Restore the hole in the case (2) with the reamer

99394017 (3) and the bushing 99394019 (1).

Restore the injector recessing, in relation to the face of the

cylinder head, with the milling cutter 99394018 (4) and

bushing 99394019 (1) that must be from 0.47 to 1.16

mm.

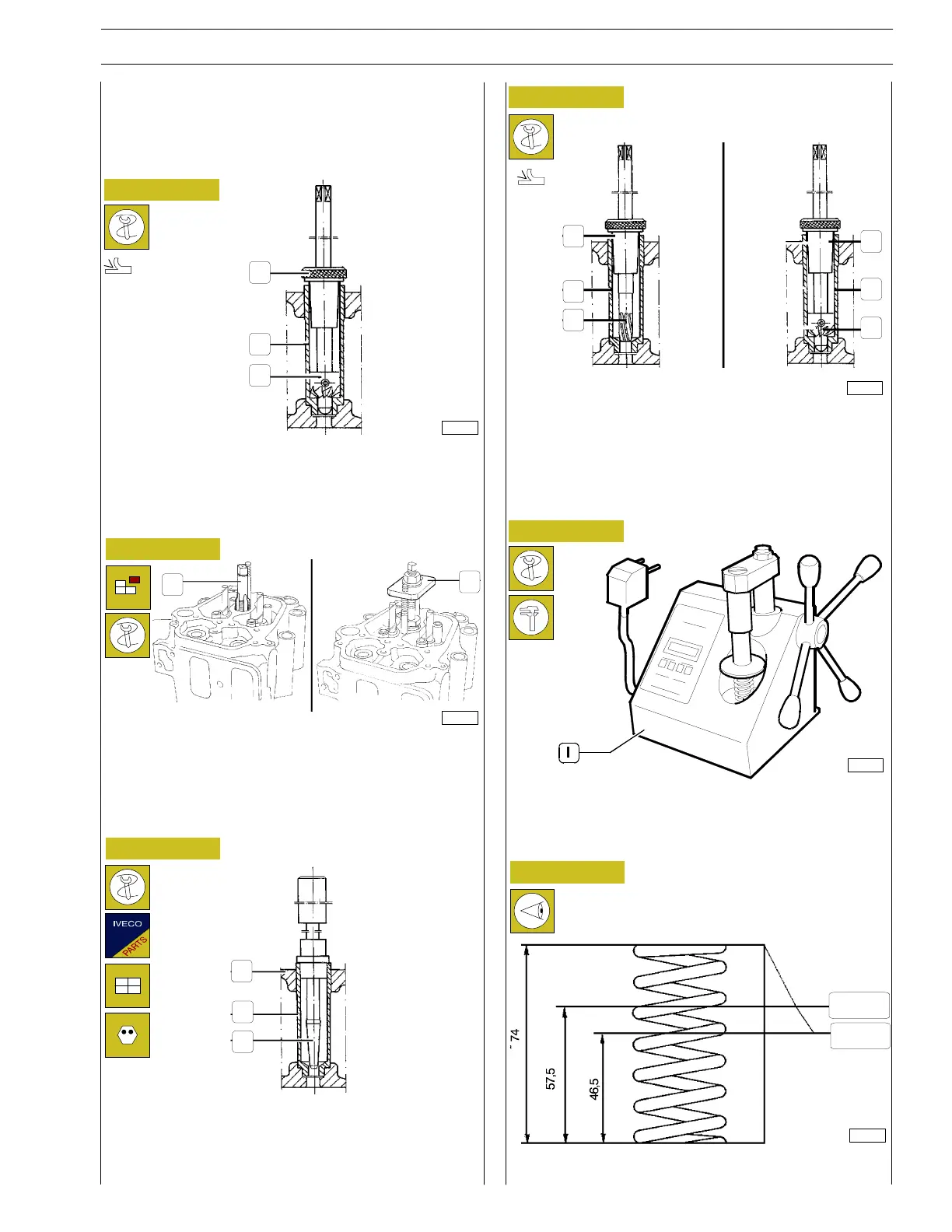

Figure 93

Figure 94

PRINCIPAL DATA FOR CHECKING SPRINGS FOR

INTAKE AND EXHAUST VALVE

kg 45± 2,5

kg 80±4

- Before mounting, check the flexibility of the valve spring

using tool 99305047. Compare the loading and

deformation data with those of the new spring indicated

in the following diagrams.

REPLACING THE INJECTOR—HOLDER

CASES

Imperfect coupling between the injector and case, forced into

the cylinder head or between the c ase and the seat on the

cylinder head, causes a loss of compression or water leakage.

In the first case, the trouble is eliminated by regrinding the seat

of the case (2) with the milling cutter 99394011 (3) and the

bushing 99394019 (1) taking account that the electro—injector

recessing from the cylinder h ead face must be from 0.47 to

1.16 mm.

In the second case, it is necessary to replace the case as follows:

- thread the case with the set of screw taps 99390800 (1);

- extract the case from the cylinder head with tool

99342145 (2).

1

2

3

1

2

1

2

3

1

2

1

2

3

4

16690

37722

82718

16859

2280

SECTION 4 - OVERHAUL AND TECHNICAL SPECIFICATIONS 37

VECTOR 8 ENGINES

Print P2D32V001E Base - April 2006

Loading...

Loading...