6-56 4181384 First Edition

HYDRAULICS

6

Disassembly and Assembly

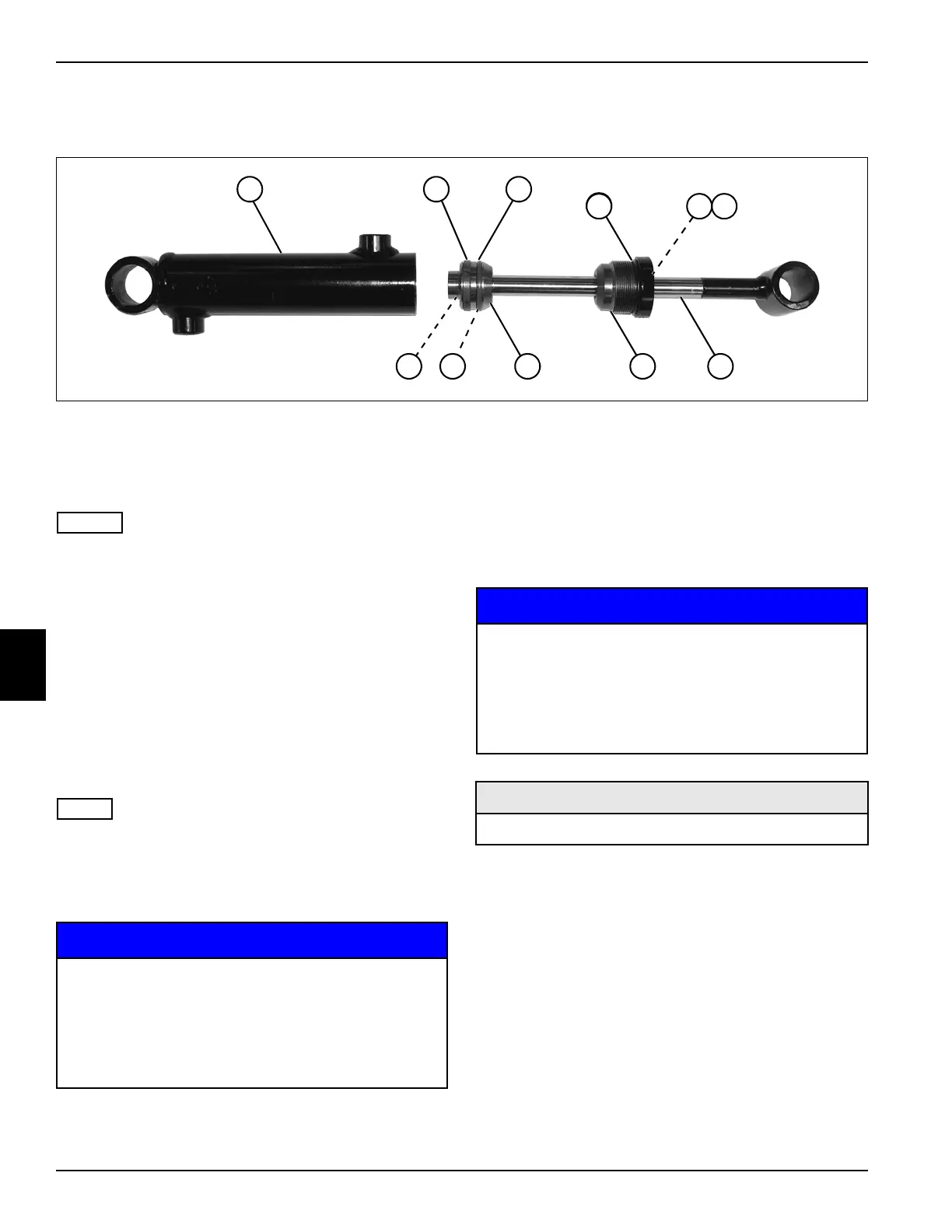

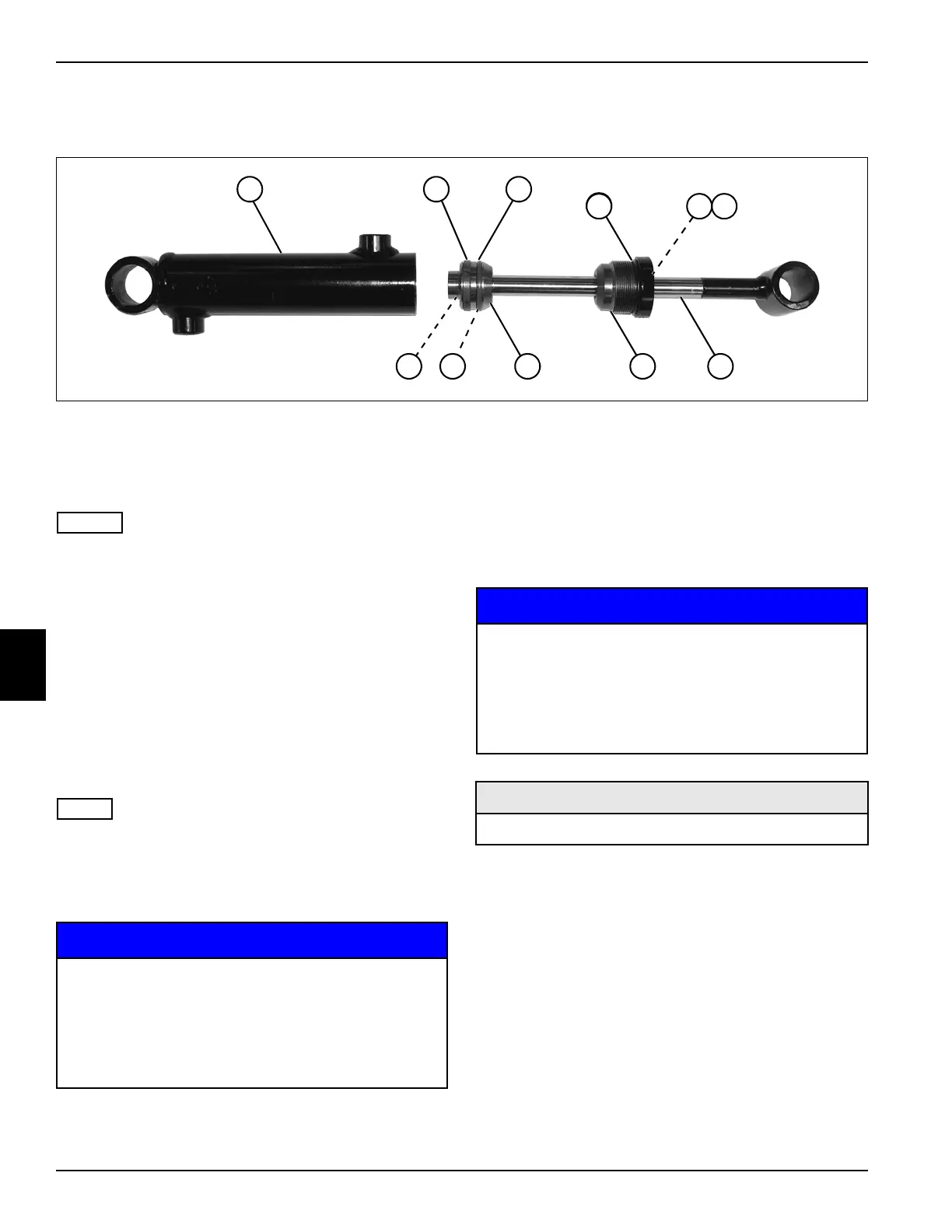

See Figure 6-53.

Figure 6-53

NOTES

• During repair of cylinder, use extreme care not to

damage the barrel, piston, rod, and sealing surfaces

of the cylinder.

• Seal kit accommodates more than one cylinder ram

design and may contain unused components. During

disassembly, retain and compare existing O-rings

and seals to seal kit components to ensure correct

O-rings and seals are used.

1. Drain oil from lift cylinder.

2. Disassemble the lift cylinder as shown.

3. Use a spanner wrench to remove rod guide assembly

(8) from barrel.

NOTE

Note orientation of rod end to barrel to ease assembly.

4. Pull rod assembly out of barrel.

5. Remove piston (9) from rod (7). Be careful not to

damage piston end when unscrewing from rod.

NOTICE

6. Clean all parts using clean solvent, and dry using

compressed air.

7. Inspect all parts for excessive wear, cracks, broken

parts and scoring of the cylinder barrel, piston, and

rod.

Assembly Notes

NOTICE

• Lubricate all parts, O-rings, seals, and wiper with

clean hydraulic oil before assembly.

• Assemble the lift cylinder by reversing the order of

disassembly.

1 Barrel 4 O-Ring 7 Rod 10 O-Ring

2 Piston Ring 5 Wiper Seal 8 Rod Guide 11 O-Ring

3 Seal 6 Rod Wiper 9 Piston

TN1318

1 2

4

6

3

8 7

4 5

91011

It is important that all components are absolutely

clean, as contamination can result in serious

damage and/or improper operation.

Never use shop towels or rags to dry parts after

cleaning, as lint may clog passages. Dry parts

using compressed air.

It is important that all components are absolutely

clean, as contamination can result in serious

damage and/or improper operation.

Never use shop towels or rags to dry parts after

cleaning, as lint may clog passages. Dry parts

using compressed air.

Required Materials

Seal Kit (Jacobsen P/N 002301010)

Loading...

Loading...