20

CORRECT CONDITION

STEP AND

ITEMS TO

CHECK

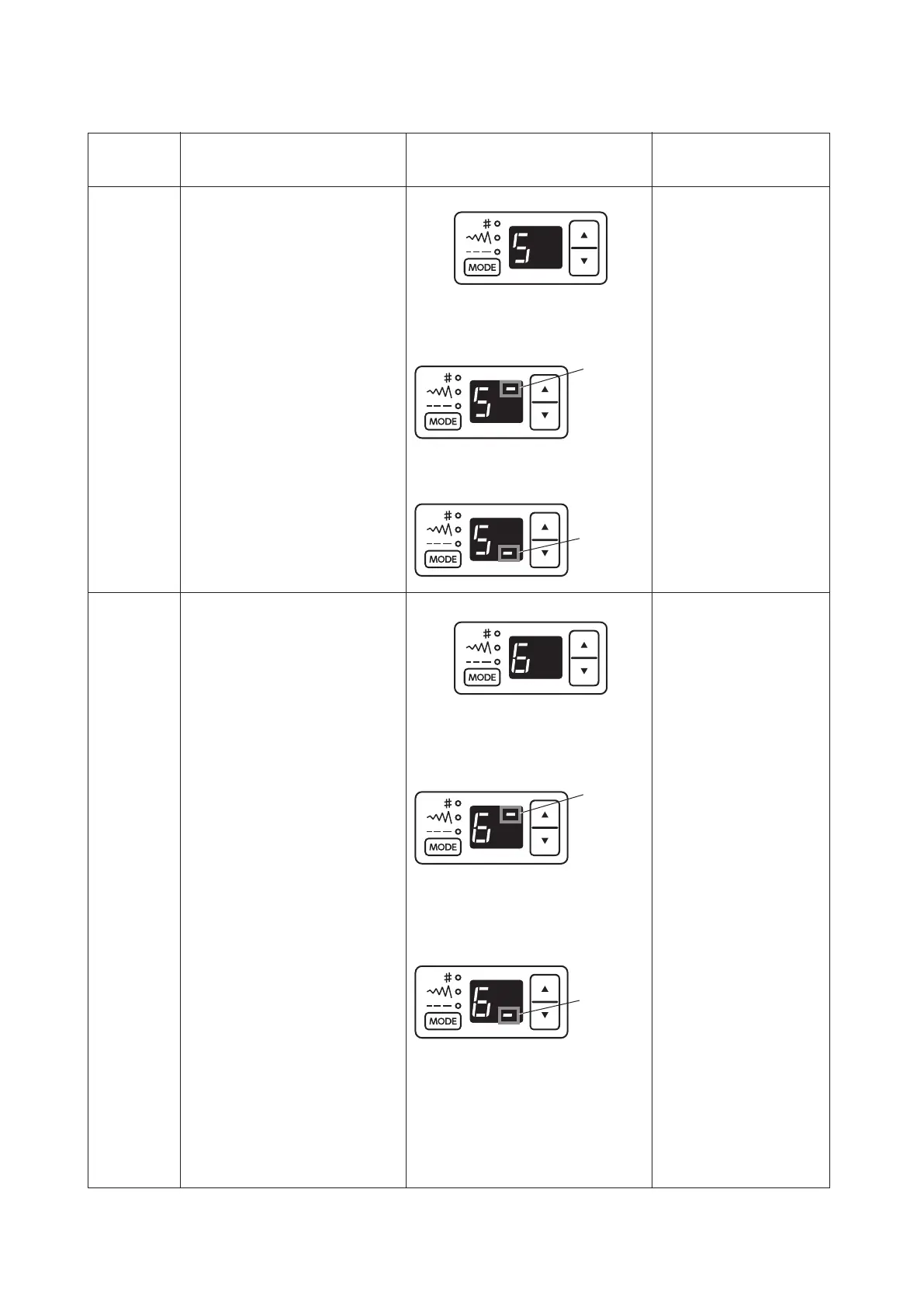

05)

UPPER SHAFT

POSITIONING

SENSOR

PROCEDURE DEFECTIVE CONDITION

Turnthehandwheeltowardyou.

Lowertheneedlebartoitslowest

position(zigzagphase).

Presstheneedleup/downbutton.

Raisetheneedlebarfromits

lowestpositiontoitshighest

position(feedphase).

Presstheneedleup/downbutton.

Iftheresultiscorrectcondition,

pressthe

MODEkey

toproceed

thenextstep.

Iftheresultisdefectivecondition,

pressthereversestitchbuttonto

proceedthenextstep.

Zigzagmotordoesnotget

defaultposition.

Buzzer does not sound.

–REMEDY–

Replacethezigzagmotor.

ReplacethecircuitboardA.

Feedmotordoesnotget

defaultposition.

Buzzerdoesnotsound.

–REMEDY–

Replacethezigzagwidth

motor.

Replacethefeedmotor.

ReplacethecircuitboardA.

Buzzerdoesnotsound.

Stitchwidthorlength

symboldoesnotappear.

–REMEDY–

ReplacethecircuitboardA.

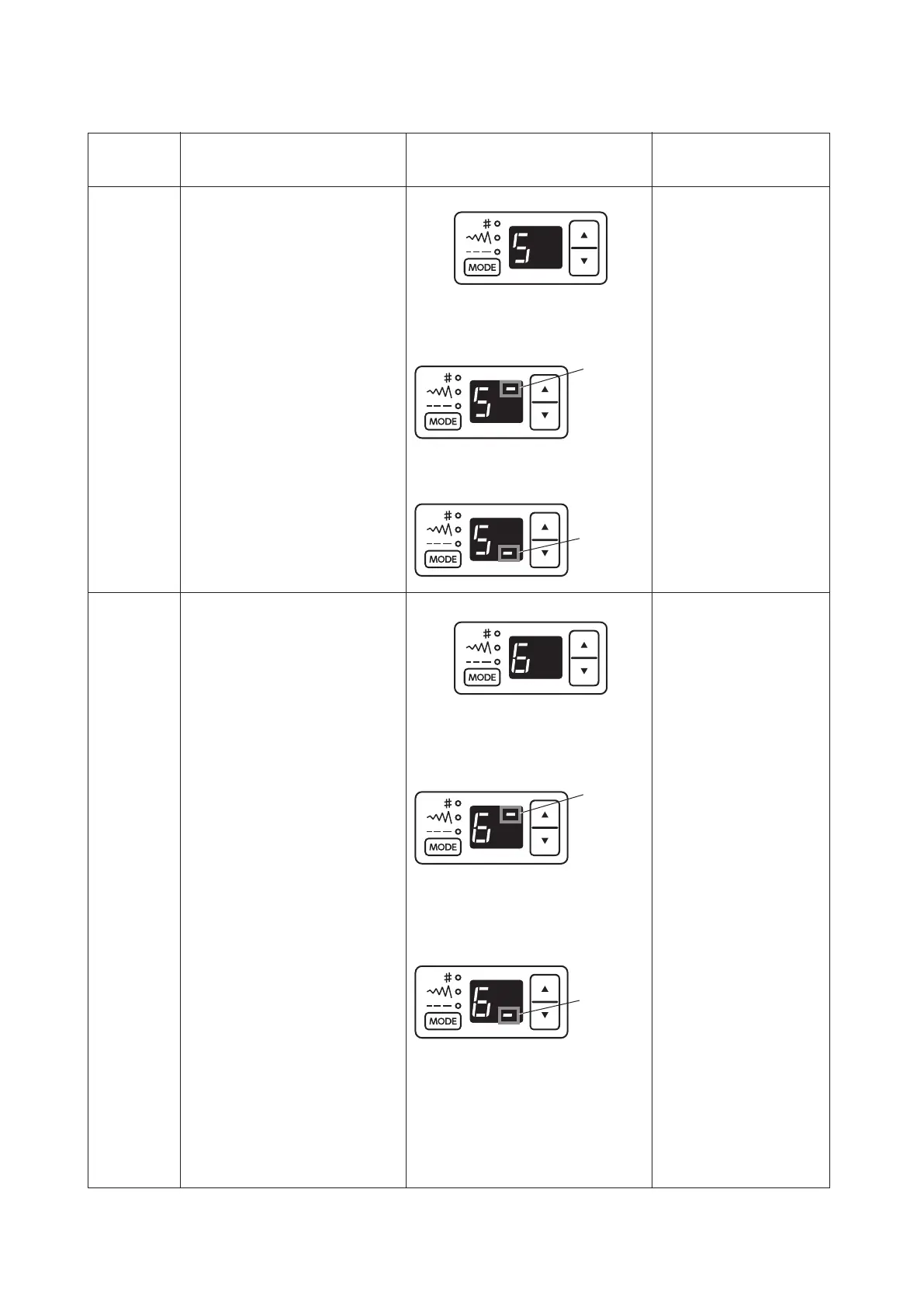

06)

ZIGZAG

MOTOR

(STEP MOTOR)

AND

FEED MOTOR

LEDdisplays“5”.

Turnthehandwheel.

LEDdisplaysthetopbarsymbol

whentheneedlebarisatzigzag

phase.

Presstheneedleup/downbutton

whenLEDdisplaystopbarsymbol.

TheZigzagmotorwillbeinitialized

andgetitsdefaultposition.

Presstheneedleup/downbutton

LEDdisplays“6”

SELF-DIAGNOSTIC TEST

Turnthehandwheeltowardyou.

Lowertheneedlebarfromits

highesttolowestposition.

Raisetheneedlebarfromits

lowestpositiontohighest

position.

Iftheresultiscorrectcondition,

pressthe

MODEkey

toproceed

thenextstep.

Iftheresultisdefectivecondition,

pressthereversestitchbuttonto

proceedthenextstep.

Topbar

symbol

Topbar

symbol

Bottom

bar

symbol

Bottom

bar

symbol

LEDdisplaysneedlelowest

positionsymbolwhentheneedlebar

isatfeedphase.

whenLEDdisplaysbottombar

symbol.

Thefeedmotorwillbeinitializedand

getitsdefaultposition.

Loading...

Loading...