Janome-America.com

Page 13

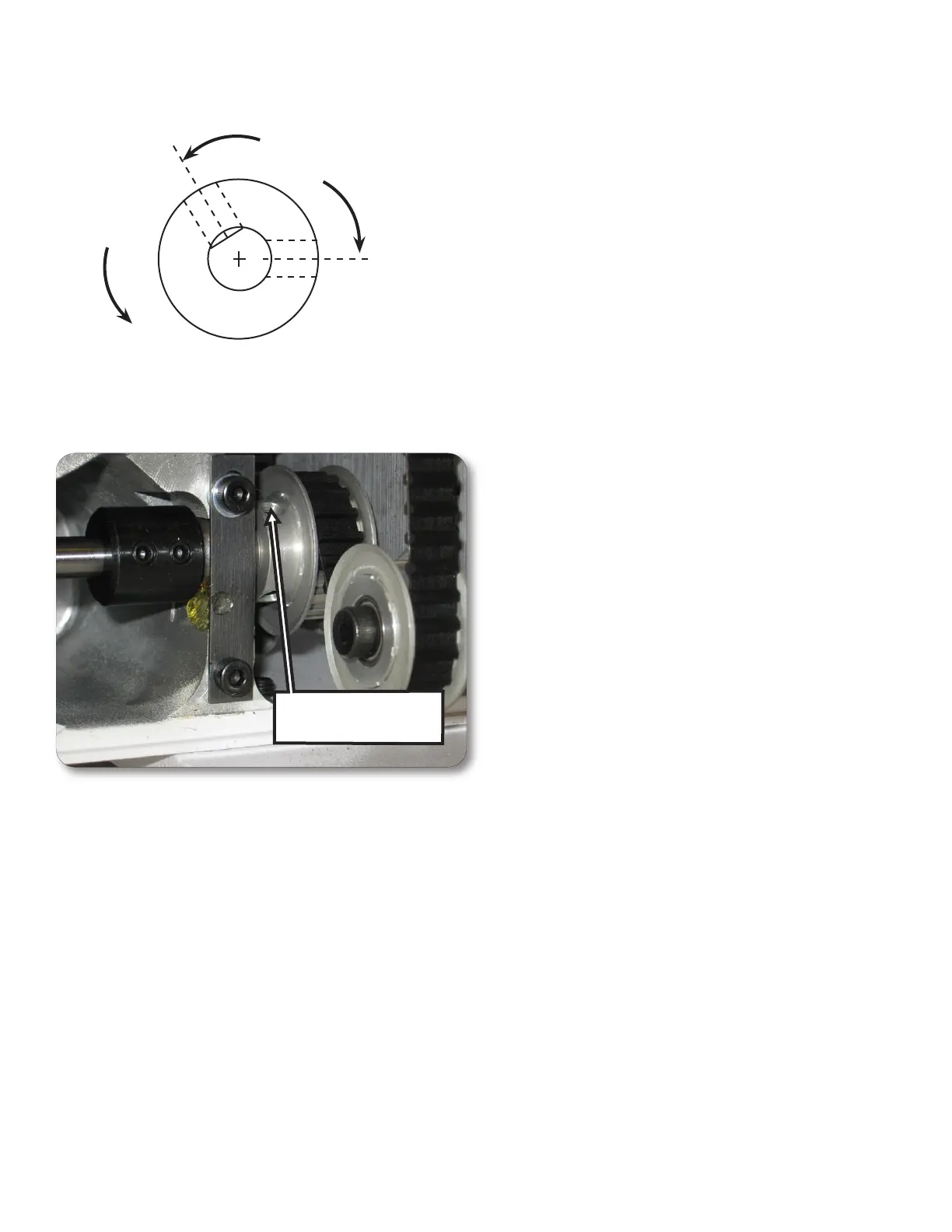

Figure 4.5

Hook-sha Timing

Pulley 1

st

screw

Hook-sha ming pulley

Tools needed: (2.5 mm handle hex tool)

Note: The hook-sha ming pulley rotates the

opposite direcon as the main sha ming pulley.

Carefully note the labeled rst screw (Figure 4.5).

Note: The hook-sha collar does not have a at.

The at is located on the hook-sha ming pulley

rst screw.

Important Hook-Sha Notes

The hook-sha turns two mes per stch and rotates

in the opposite direcon as the main sha. Please

carefully note which screw is the rst screw in the

direcon of moon and on the at.

The hook-sha pulley is set to a specic seng from

the end of the sha to allow proper needle-to-hook

distance adjustment. Adjust the collar to remove axial

play, not the hook-sha pulley, or the seng can be

thrown o, which may make it so needle-to-hook

distance cannot be adjusted.

The QMP 18 VERSA ulizes long collars with two

screws in line to help prevent the collar from pping

when ghtened, causing variaon of ghtness or

play, as the collar rotates 360º. To ensure that there

is no ghtness or play, the collar should be checked

through a full rotaon unl it has minimal ghtness

and minimal play.

4. Checking and Securing Flats and Screws - Connued

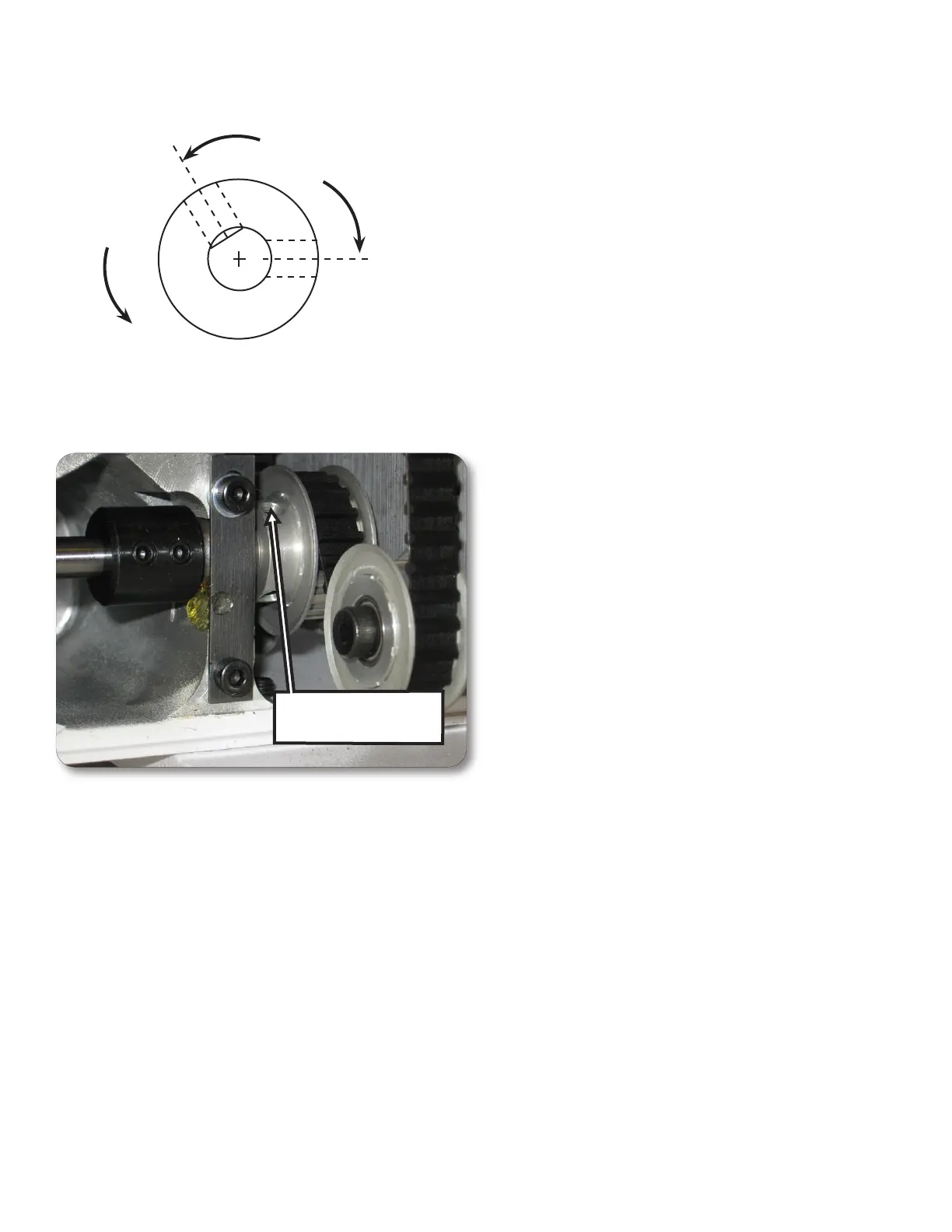

First Screw, First Posion Rule

The rst screw or rst posion is almost always*

located 120° apart in the direcon of rotaon from

the second screw or second posion. The rst screw

in direcon of rotaon goes on the at. (Figure 4.4)

* (The pitman screws are only 90 degrees apart

instead of 120 degrees.)

120

o

Position 2

Direction of

Rotation

Position 1

Figure 4.4

Note: First screw in direcon of moon goes on the

at. The rst screw is 120º before the 2nd screw. The

2nd screw is then 240 degrees before the 1st screw.

Loading...

Loading...