Page 55 of 97

4– USE OF THE MACHINE IN

REGULAR WORKING CONDITIONS

______________________________________________________________________________________________

4.3 Use of the crane

Once the machine is correctly stabilized (crane LED on), the 2-way solenoid valve automatically

makes oil flow from the truck to the crane system.

Key switch on LOCAL position:

Use the joysticks to carry out the moves indicated

o When the central key switches are up

, the crane can be operated (green moves)

o When the central key switches are down

, the jib can be operated (yellow moves)

Key switch turned to REMOTE position:

When the key switch is in this position, the radio remote control is activated:

o Start the radio remote control

o Use the uniaxial analogical joysticks to operate the crane and the jib

4.4 From crane configuration to truck configuration

CAUTION: switching from crane to truck configuration is possible only if the crane boom is in a

central horizontal position and carrying no load – the LED lit on the switchboard indicates that the

corresponding configuration is activated.

4.5 Stop and laying-up of the machine

• Make sure that the crane boom is in a central horizontal position and carrying no load

• Turn the key switch on the LOCAL position

• Retract the stabilizers and park the machine

• Turn the cutout switch on the OFF position

• Turn the battery switch on the OFF position

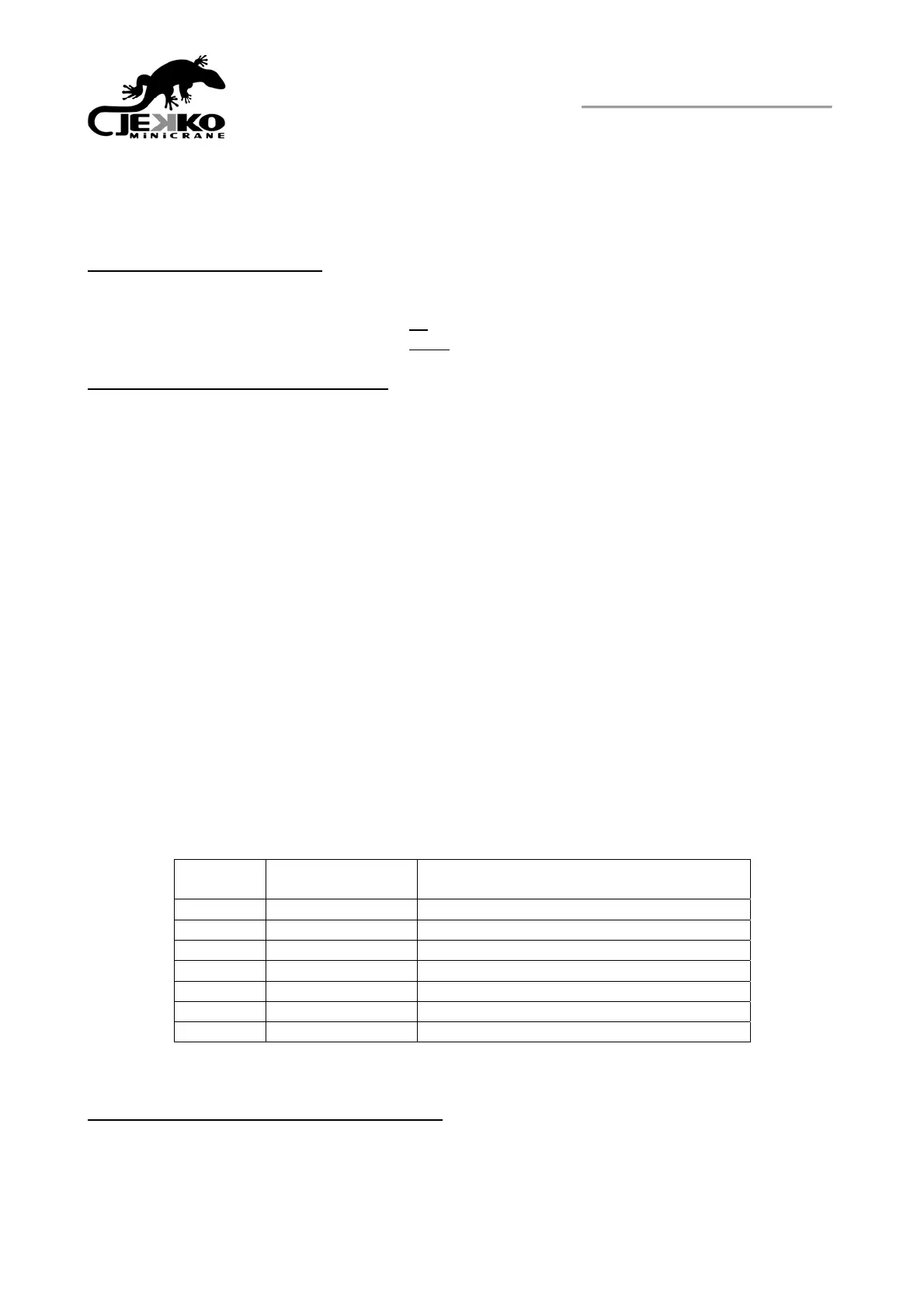

4.6 Settings of the tools installed

Access to page N° 6 MACHINE OPERATOR on the MAIN MENU:

1- in underpage “n° tool” select the number corresponding to the tool installed

ALUE SYMBOL ON

DISPLAY

DESCRIPTION

0 O Winch

1 M Manipulator MV300.3

2 JH Hydraulic jib with hook

3 JM Mechanical jib

4 H Hook

5 M2 Manipulator MR800.4

6 JW Hydraulic jib with rope

2- in underpage “n° rope” select the kind of line pull (single, double, triple) installed on the

winch

Once the values are set, save them on page 9.

For the tool use, see the relative section or the manual supplied.

Loading...

Loading...