Page 66 of 97

8 – TROUBLESHOOTING

______________________________________________________________________________________________

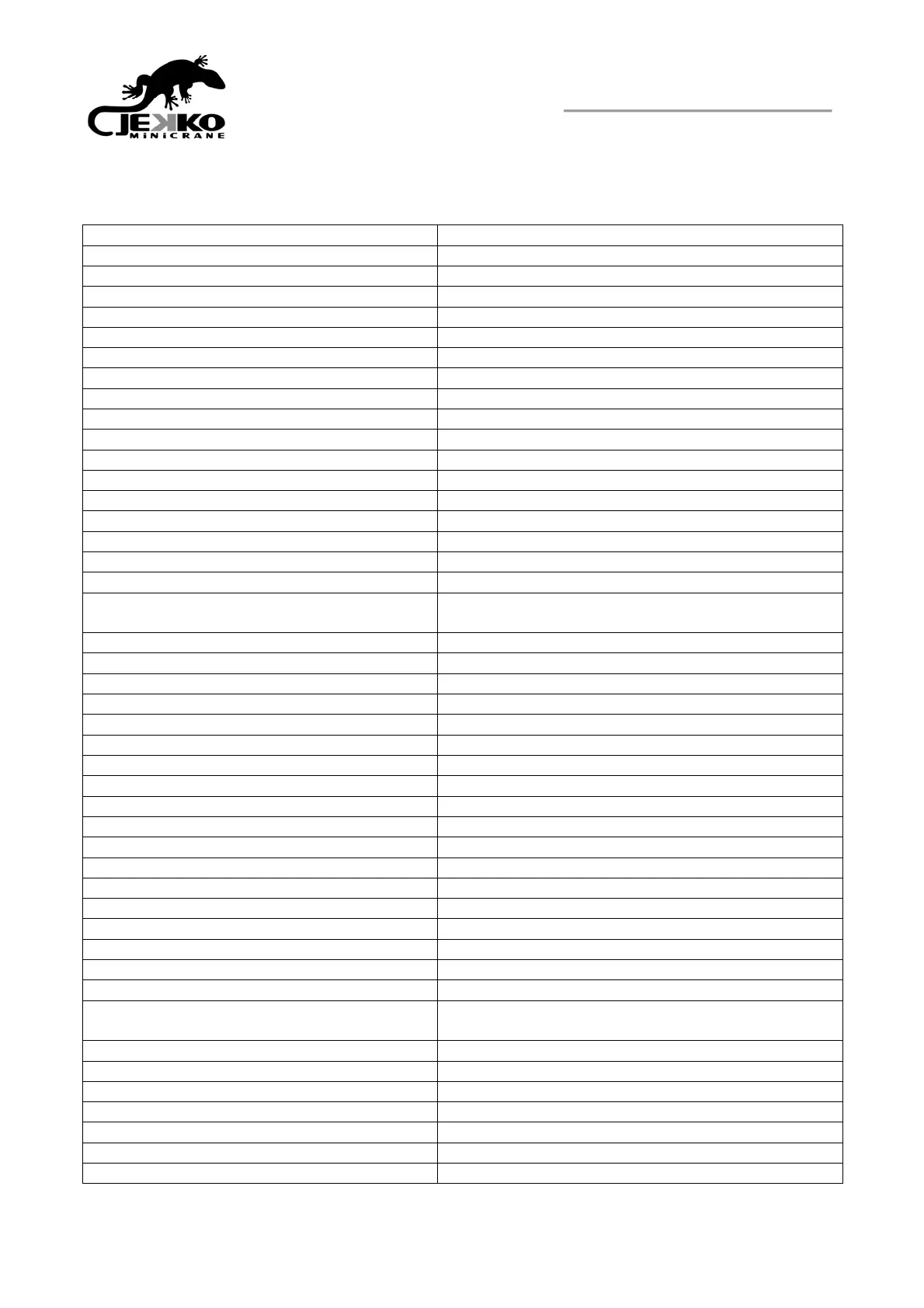

8.4 Machine alarms

ALARMS

CTION

1 alarm E2PROM HEAD → 1° Check fuses >2°Call service

2 pressure transducer disconnected → Check pressure transducer wiring

3 pressure transducer short-circuited → 1° Check fuses >2°Replace it

4 jib pressure transducer disconnected → Check jib pressure transducer wiring

5 jib pressure transducer short-circuited → 1° Check fuses >2°Replace it

6 winch strain gauge disconnected → Check strain gauge wiring

7 winch strain gauge short-circuited → 1° Check fuses >2°Replace it

8 angle sensor disconnected → Check wiring

9 angle sensor short-circuited → 1° Check fuses >2°Replace it

12 angle sensor disconnected → Check wiring

13 angle sensor short-circuited → 1° Check fuses >2°Replace it

14 angle sensor wrong value → Make calibration

15 Hydraulic Jib angle sensor disconnected → Check wiring

16 Hydraulic Jib angle sensor short-circuited → 1° Check fuses >2°Replace it

30-35 timeout (1-2-3-4-5-6) CANBUS ARM → 1° Check fuses >2°Call service

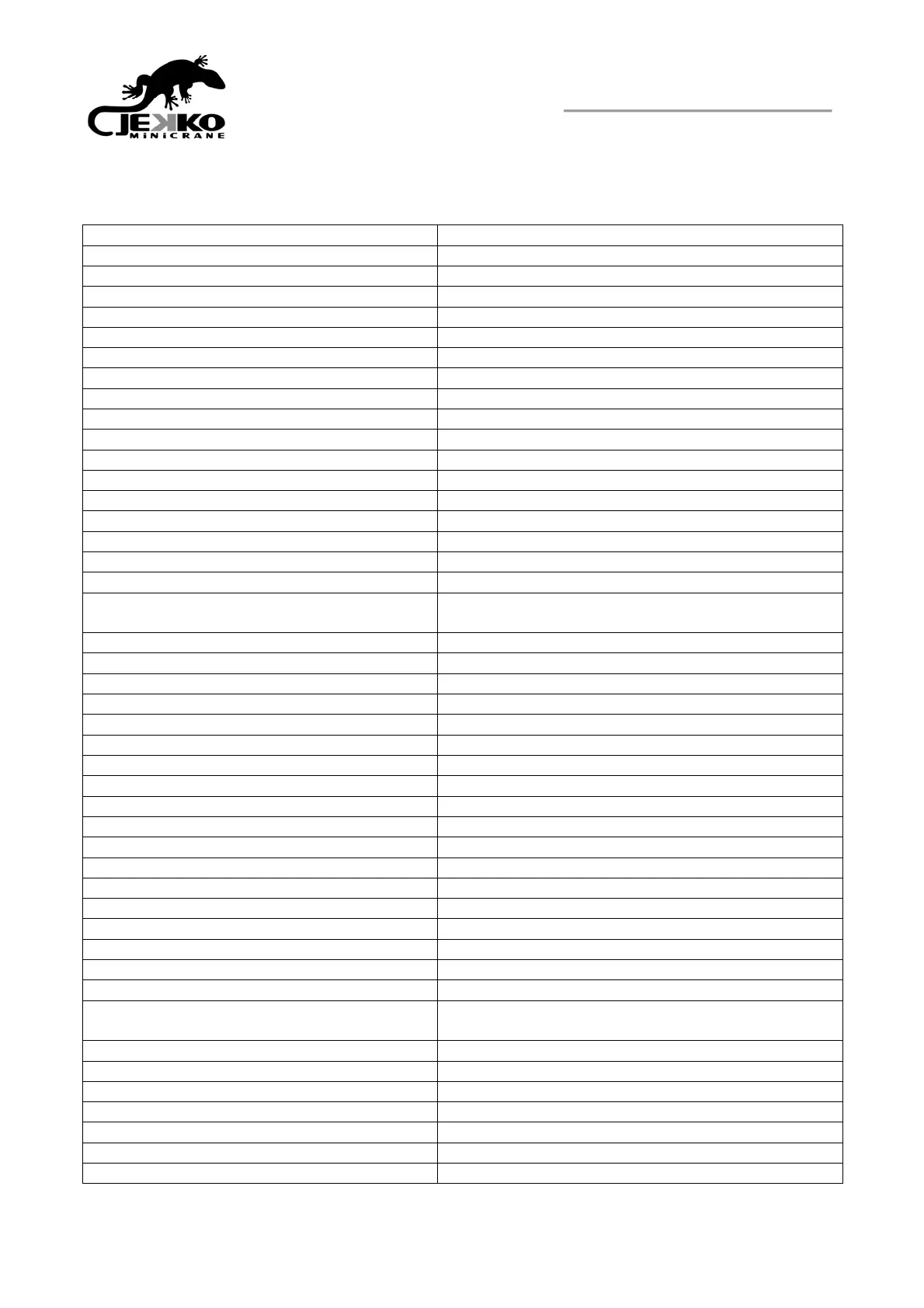

WARNINGS

CTION

10 local emergency held down → Reset the machine emergency push button

11 remote emergency held down → Reset the radio remote control emergency push

button

40-45 maintenance alarm → Carry out scheduled maintenance

51 block due to max pressure → Activate allowed function by the machine

52 block due to min pressure → Lift the boom

53 block due to max load → Lay the load to the ground or change n° of rope

54 block due to rope up → Unwind the rope or telescope in

55 block due to rope down → Wind the rope

56 block due to machine instability SPD360 → Activate allowed function by the machine

57 clockwise slewing block SPD265 → Turn the boom to the opposite sector

58 counterclockwise slewing block SPD265 → Turn the boom to the opposite sector

59 block due to pressure transducer alarm → Check and/or replace for probable failure

60 block due to jib pressure transducer alarm → Check and/or replace for probable failure

61 block due to winch strain gauge alarm → Check and/or replace for probable failure

62 block due to angle sensor alarm → Check and/or replace for probable failure

63 block due to anticollision → Lower the boom

64 block due to global safety system → 1° Check fuses >2°Call service

65 block due to max angle → Lower the boom

66 slowing down because of the anticollision → No action, safety system

67 slowing down because of the max angle → No action, safety system

68 block of mechanical jib → You are not on a correct jib lifting area, see

lifting diagram!

70 block due to wrong tool selected → Select the right tool on the menu

71 slewing block → Activate allowed function by the machine

72 hook lifting tool → Winch is automatically locked

73 clockwise slewing block SPD360 → Restore the correct stabilisation of the machine

74 counterclockwise slewing block SPD360 → Restore the correct stabilisation of the machine

75 wrong stabilisation SPD360 → Restore the correct stabilisation of the machine

76 wrong stabilisation SPD500 → Restore the correct stabilisation of the machine

Loading...

Loading...