Electrical System

9.28

3507, 3508, 3509, 3512, 3513, 4007, 4008, 4009, 4012, 4013

c. Main Control Valve Solenoid Installation

1. Install the valve solenoid using new o-rings and

tighten the allenhead screws. Do not over tighten.

2. Connect the wire connector to the valve solenoid.

3. Connect the battery negative (-) cable to the battery

negative (-) terminal.

4. Start the machine and slowly move joystick to

engage function. If further troubleshooting is

required, refer to Section 9.5, “Electrical System

Schematics,” or Section 8.5, “Hydraulic Schematics.”

5. Close and secure the engine cover.

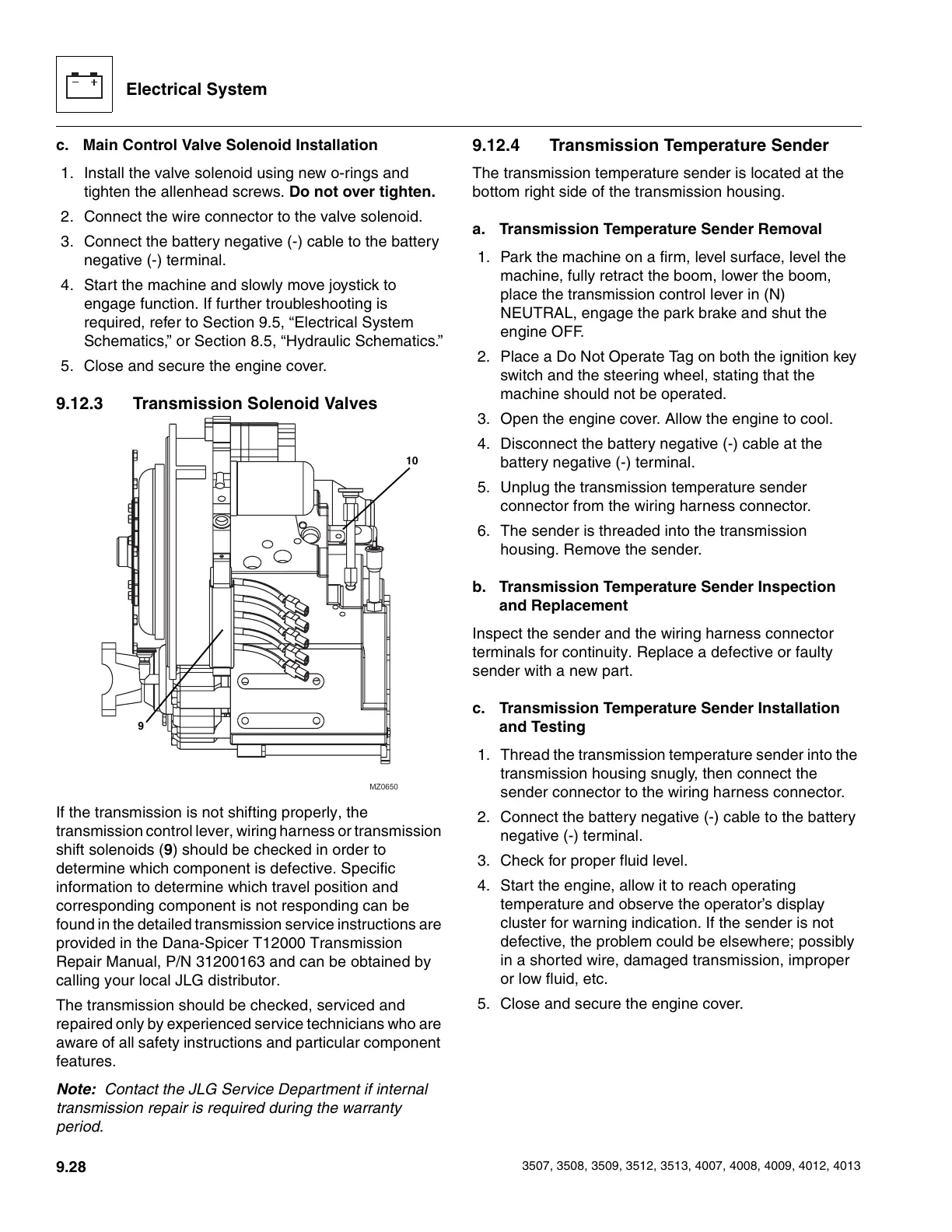

9.12.3 Transmission Solenoid Valves

If the transmission is not shifting properly, the

transmission control lever, wiring harness or transmission

shift solenoids (9) should be checked in order to

determine which component is defective. Specific

information to determine which travel position and

corresponding component is not responding can be

found in the detailed transmission service instructions are

provided in the Dana-Spicer T12000 Transmission

Repair Manual, P/N 31200163 and can be obtained by

calling your local JLG distributor.

The transmission should be checked, serviced and

repaired only by experienced service technicians who are

aware of all safety instructions and particular component

features.

Note: Contact the JLG Service Department if internal

transmission repair is required during the warranty

period.

9.12.4 Transmission Temperature Sender

The transmission temperature sender is located at the

bottom right side of the transmission housing.

a. Transmission Temperature Sender Removal

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, lower the boom,

place the transmission control lever in (N)

NEUTRAL, engage the park brake and shut the

engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

3. Open the engine cover. Allow the engine to cool.

4. Disconnect the battery negative (-) cable at the

battery negative (-) terminal.

5. Unplug the transmission temperature sender

connector from the wiring harness connector.

6. The sender is threaded into the transmission

housing. Remove the sender.

b. Transmission Temperature Sender Inspection

and Replacement

Inspect the sender and the wiring harness connector

terminals for continuity. Replace a defective or faulty

sender with a new part.

c. Transmission Temperature Sender Installation

and Testing

1. Thread the transmission temperature sender into the

transmission housing snugly, then connect the

sender connector to the wiring harness connector.

2. Connect the battery negative (-) cable to the battery

negative (-) terminal.

3. Check for proper fluid level.

4. Start the engine, allow it to reach operating

temperature and observe the operator’s display

cluster for warning indication. If the sender is not

defective, the problem could be elsewhere; possibly

in a shorted wire, damaged transmission, improper

or low fluid, etc.

5. Close and secure the engine cover.

MZ0650

9

10

Courtesy of Crane.Market

Loading...

Loading...