Electrical System

9.30

3507, 3508, 3509, 3512, 3513, 4007, 4008, 4009, 4012, 4013

9.12.7 Engine Oil Pressure Sender

The engine oil pressure sender is located below the

injector pump.

a. Engine Oil Pressure Sender Removal

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, lower the boom,

place the transmission control lever in (N)

NEUTRAL, engage the park brake and shut the

engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

3. Open the engine cover. Allow the engine to cool.

4. Disconnect the battery negative (-) cable at the

battery negative (-) terminal.

5. Unplug the engine oil pressure sender connector

from the wiring harness connector.

6. The sender is threaded into the engine block.

Remove the sender.

b. Engine Oil Pressure Sender Inspection and

Replacement

Inspect the sender and the wiring harness connector

terminals for continuity. Replace a defective or faulty

sender with a new part.

c. Engine Oil Pressure Sender Installation and

Testing

1. Thread the engine oil pressure sender into the

engine block snugly, then connect the sender

connector to the wiring harness connector.

2. Connect the battery negative (-) cable to the battery

negative (-) terminal.

3. Check for proper oil level.

4. Start the engine, and observe the operator’s display

for warning indication. If the sender is not defective,

the problem could be elsewhere; possibly in a a

shorted wire, improper-running engine, low oil,

obstructed or faulty oil pump, defective instrument

display.

5. Close and secure the engine cover.

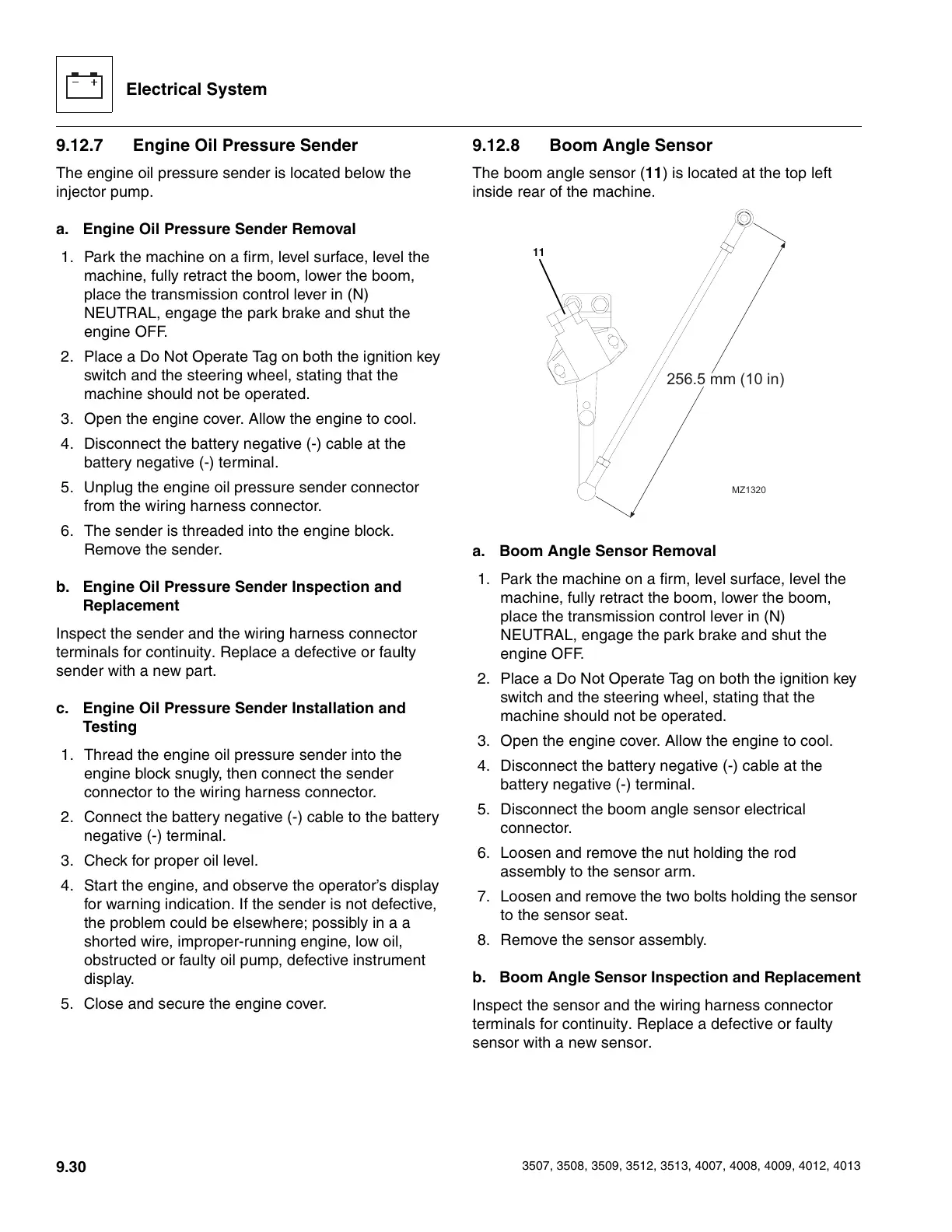

9.12.8 Boom Angle Sensor

The boom angle sensor (11) is located at the top left

inside rear of the machine.

a. Boom Angle Sensor Removal

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, lower the boom,

place the transmission control lever in (N)

NEUTRAL, engage the park brake and shut the

engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

3. Open the engine cover. Allow the engine to cool.

4. Disconnect the battery negative (-) cable at the

battery negative (-) terminal.

5. Disconnect the boom angle sensor electrical

connector.

6. Loosen and remove the nut holding the rod

assembly to the sensor arm.

7. Loosen and remove the two bolts holding the sensor

to the sensor seat.

8. Remove the sensor assembly.

b. Boom Angle Sensor Inspection and Replacement

Inspect the sensor and the wiring harness connector

terminals for continuity. Replace a defective or faulty

sensor with a new sensor.

MZ1320

256.5 mm (10 in)

11

Courtesy of Crane.Market

Loading...

Loading...